Smart Actuators Offer New Motion Control, Economic, Flexibility and Safety Advantages for Truck and Off-Highway Vehicles

Smart actuators are making operation of heavy duty automotive and mobile off highway (MOH) equipment easier, safer and less expensive. Thanks to digital intelligence and connectivity built into the actuator housing itself, smart linear actuators can track critical parameters remotely and react to them automatically. They can deliver real-time operating status, and network flexibly and inexpensively with other systems. Compared to hydraulic and pneumatic options, smart actuators provide a smaller component footprint; greater control and accuracy; lower maintenance and energy costs; and quieter operation.

Truck and off-highway vehicles are integrating smart actuators in order to enhance their communication, control and performance.

Enriching the man/machine dialogue

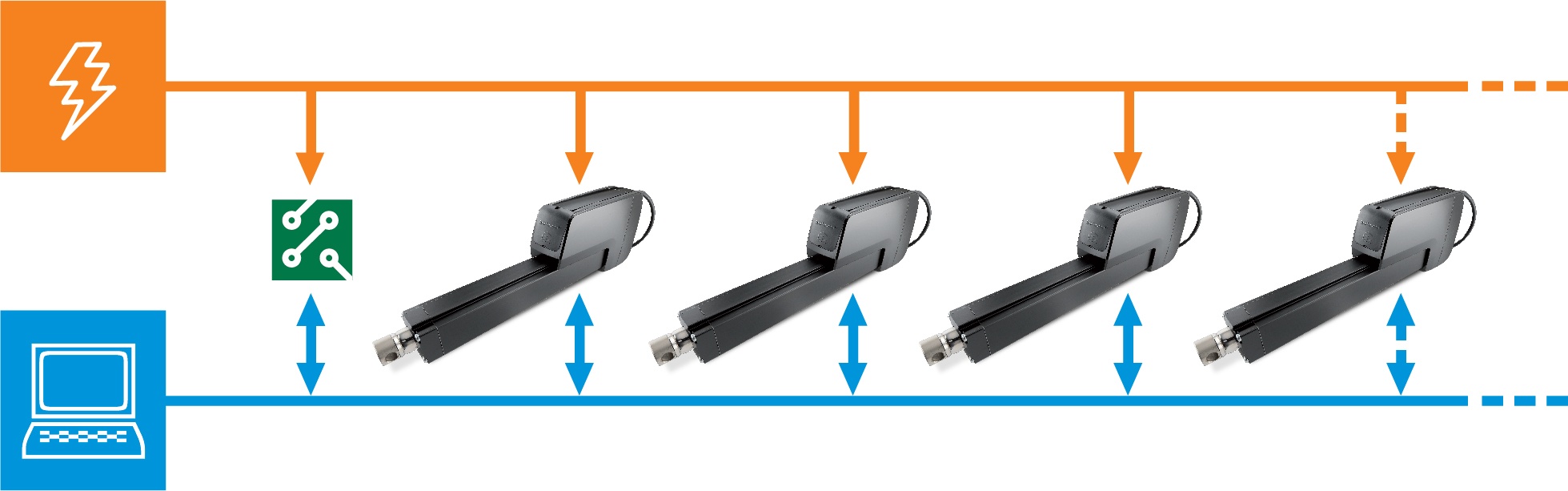

Smart actuators communicate with a vehicle’s electronic control unit (ECU), reducing the need for multiple, single-function controllers or multiple ECUs. They can accept commands and provide status information in return. They know their position and speed, and monitor safety related data such as load or temperature. (Figure 1) This information provides the basis for a dialogue between the end user and the device. Support for networking standards such as J1939 CAN bus provides the channel over which that dialogue takes place.

Figure 1 - Smart actuators integrate electronics within the actuator housing, enabling switching, synchronization and networking to be managed automatically based on signals from a common external source, such as a programmable logic controller (PLC).

Deploying J1939-compatible communications in tandem with advanced embedded electronics gives users greater ability to tell each actuator how fast to move, and where to move and stop. And once that signal is sent, users can receive instant feedback as to whether the actuator has behaved as instructed. (Figure 2)

Figure 2: Smart actuators exchange operating data across a vehicle’s digital network using only two wires.

Having a comparable dialogue with an actuator that is not on a network would require an external infrastructure involving wired-in encoders, limit switches, potentiometers and switches. Smart actuators achieve comparable functionality, but with capability designed into their electronics. Removing the complexity of the external infrastructure frees control system designers and users to focus on applications objectives, while reducing footprint and operating costs, and improving installation and maintenance efficiency.

Smart position control

Such advanced position control and switching enables programming of the drive to perform with an infinite number of movement profiles and custom motion strategies. Users can, for example, program the actuator to seek forward a few millimeters or make a small set of movements back and forth to reach a desired position.

And because the system knows what it is supposed to do and monitors performance in real time, it can flag potential variances and trigger advanced algorithms to manage alarms, corrections or shutdown. Here are just some of the capabilities that embedded electronics and communications can offer:

• Integrated motor control, which enables operation and controllability via digital and/or analog I/O.

• Analog and digital position feedback, which enables a higher level of controllability.

• Synchronization, which enables multiple actuators to self adjust to handle large or awkward loads.

• Condition monitoring of critical parameters such as voltage, current and temperature.

• Electronic load monitoring, which ensures consistent overload protection.

• Dynamic braking, which reduces coast at the end of stroke, improving repeatability.

• End-of-stroke Indication, which improves both safety and performance.

Smart diagnostics and maintenance

In addition to returning real-time performance data, constant monitoring of temperature, current, speed and voltage has maintenance benefits as well. This enables advanced diagnostics, self-testing and error handling, and transmitting feedback across the network as quickly as ten times per second. If the system detects a problem, surpassing a temperature threshold for example, the actuator can finish its program and send an error flag to the computer, all in fractions of a second.

Although smart actuators themselves require little maintenance, self-monitoring can reduce overall maintenance costs by sensing wear or helping synchronize replacement schedules with planned machine downtime. They can also share monitoring data in the cloud so that technicians anywhere in the world can dial in to troubleshoot a particular actuator. If an actuator needs replacing, it would take only about twenty minutes, compared to the hours or even days of troubleshooting, disassembly, reassembly, system bleeding and testing that might be required of a fluid-driven actuator.

Application flexibility

Because so much functionality is software defined, digital actuators offer significant application flexibility as well. The same actuator configured to operate with a 500-pound trip point, for example, could be reconfigured for 2000-pound trip point. Such universal applicability eliminates the need to implement a separate controller for each application, while reducing engineering time, wiring and spare inventory carrying costs.

Ergonomics

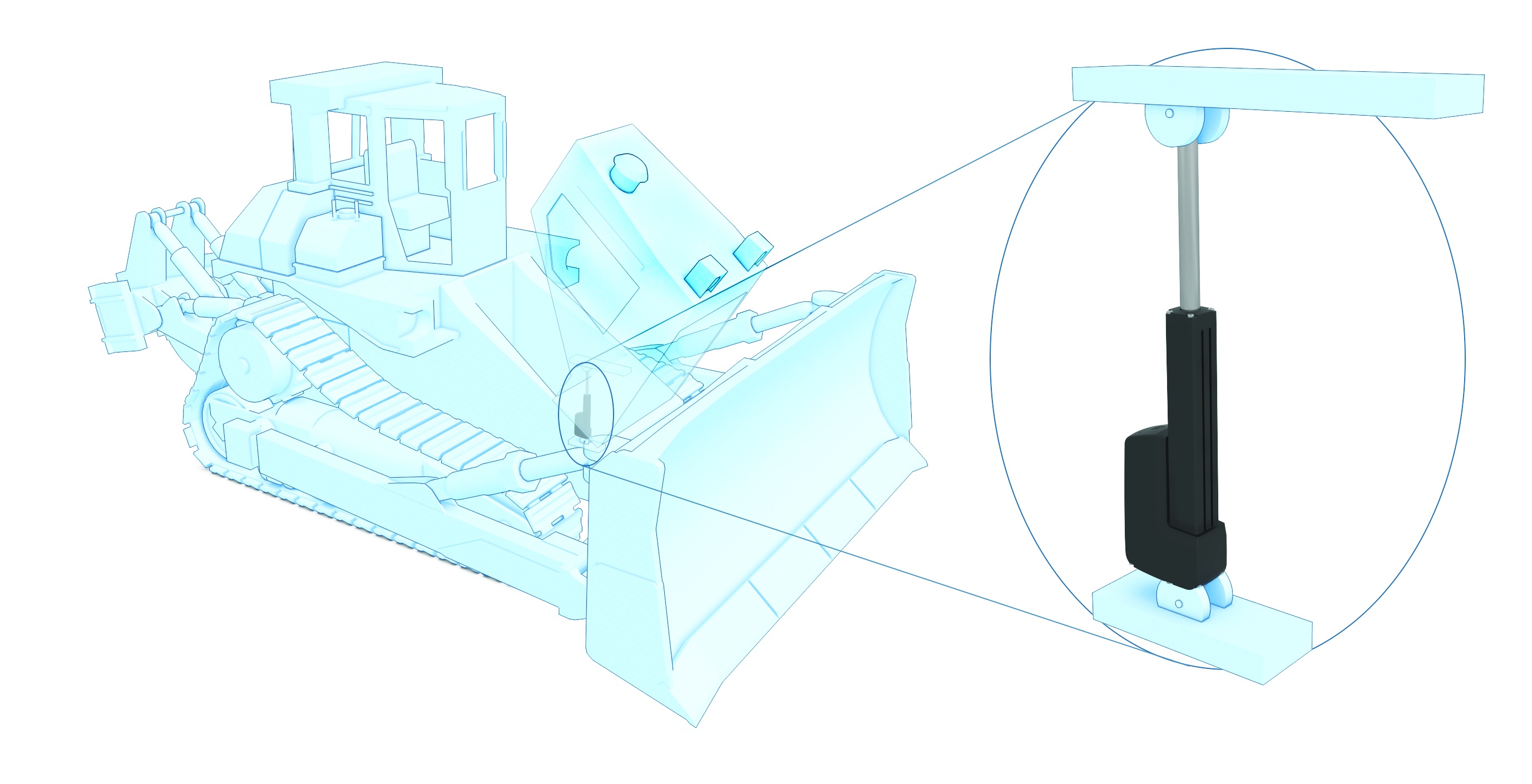

Digitization can also improve ergonomics. For example, operators of many MOH vehicles raise the hood to check the engine compartments by deploying an actuator on one or other side of the hood to help raise and lower. But for larger engine compartments with heavier hoods, it is more difficult to handle. Therefore, deploying an actuator on each side of the hood and synchronizing both across the vehicle network makes lifting and lowering hoods easier and safer.

Lifting and lowering heavy hoods is now easier and safer with smart actuators.

The smart edge

Smart actuators provide many benefits to users like efficiency, precision and network flexibly. Their digital intelligence is another key component that makes the actuators stand out from the rest.

The electronic and communications technologies that enable digitization of truck and MOH technology is already quite mature. There are many opportunities to gain position control, maintenance, ergonomics and other benefits today. The challenge is to develop the applications that give original equipment manufacturers and end users true competitive advantage.

Part of this involves addressing non-technological barriers to innovation, such as safety regulations. Self-driving tractor technology, for example, is well-advanced from a performance standpoint, but a number of regulatory and liability hurdles must be addressed before it will become part of a standalone agricultural workforce.

One thing for sure, though, is that trucks and MOH vehicles will be actively involved in the Internet of Things, as their components increasingly synchronize, and communicate with each other and other industrial applications.