As electric actuators advance in load handling, durability and intelligence, their potential as hydraulic cylinder replacements continues to grow. Depending on your initial objectives for specifying hydraulic cylinders, there are an increasing number of electric alternatives that might meet — or even exceed — those specifications. If you specify hydraulic actuators, taking some time to evaluate the widening range of electric options available for your next application could pay off handsomely.

Higher power than expected

Up until about a few years ago, a machine designer building an application such as a signage boom truck would likely have used hydraulic cylinders. If built with hydraulic cylinders, the machine would have needed an oil reservoir, a system of tubing to bring the fluid from the reservoir to the cylinder, and a set of power cables running throughout the boom. Leakage is a possibility at any point, and maintenance demands are high.

A modern electric option for such applications is a hybrid actuator that integrates the lifting capability of a hydraulic system with the cleanliness, compactness and controllability of an electric linear actuator. This combination delivers up to 4800 lbs. of force in an electrically powered unit that functions without a complex system surrounding it.

Figure 1. This H-Track electro-hydraulic linear actuator from Thomson can handle up to 4800 lbs. (21kN) of force in a clean, compact enclosure that also has shock handling capabilities comparable to a hydraulic system.

Figure 1. This H-Track electro-hydraulic linear actuator from Thomson can handle up to 4800 lbs. (21kN) of force in a clean, compact enclosure that also has shock handling capabilities comparable to a hydraulic system.

Furthermore, the unit will also deliver shock handling performance comparable to a fully hydraulic system. The boom on the signage truck mentioned earlier, for example, might be subject to wind shear that could damage components of a traditional electric actuator. A hydraulic/electric hybrid system, however, would absorb these sudden shocks. (Figure 1)

Longer life than previously available

Machine designers building simple applications in which basic movements repeat with high frequency have also typically deployed hydraulic solutions. These provide an acceptable duty cycle of 40 to 80 percent, which contributes to a longer life, but a substantial part of that life is used up in order to maintain the actuator.

The pantographs that city buses use to connect and reconnect with power sources while moving from suburban to downtown areas, for example, have traditionally used hydraulic cylinders, but adequately maintaining them requires taking them down for cleaning and lubricating ̶ all of which disrupts service and adds labor costs.

Traditional electric actuators would offer clean, maintenance-free operation for such applications, but many existing solutions were not the best fit for the application. Lower-priced options, for example, are cost-competitive with hydraulic cylinders options but they use brushed AC motors, which limit actuator life because friction from the brushes causes overheating. Higher-end actuators that use brushless stepper or servo motors, at the other extreme, would not overheat but would not be cost-justifiable for such a basic operation.

A new generation of long-life, high-duty electric actuators has emerged that enables their use for simple, repetitive operations. Instead of using a servo, stepper or brushed AC electric motors, long-life actuators typically use brushless DC motors. Unlike a brushed AC motor, which will overheat at high duty cycles, the brushless DC motors generate no friction, enabling duty cycles of up to at least 35 percent or, depending on the load and ambient temperature, up to 100 percent.

Other features contributing to a long-life actuator’s durability are double-circuit nuts and larger screws, which reduce another common point of actuator wear and can extend cycles from 30 or 40 thousand to about one million, improving travel time by orders of magnitude. Additional life-extending design features include strengthened screws and extra-angular contact bearings.

Together, such features can extend actuator life 10 times more than a brushed motor-driven actuator that might previously have been deployed in transport-grade industrial applications And, as compared to stepper- or servo-driven solutions, brushless DC motor-driven actuators are more compact because they don’t need gearing configurations. Long-life actuators are also typically sealed for high ingress protection and lubricated for life in the factory, thereby requiring zero additional maintenance.

Figure 2: The long-life Thomson Electrak® LL actuator is designed for high duty cycle applications that do not need high precision. It features a DC brushless motor, larger shaft and screw supports, and other innovations that extend its life up to 10 times over brushed motor-driven actuators. It is also maintenance-free, able to withstand challenging environmental conditions, and can run on a 24V battery or rectifier.

And as an added benefit, because DC-brushed, motor-driven actuators can be run totally on 24V battery power, they are also a good choice for mobile applications with simple, repetitive mobile operations. (Figure 2)

Command and control

Another opportunity for an electric actuator to replace a hydraulic actuator is when the designer is trying to add some control capabilities. It is possible to add a modicum of control and precision to hydraulic installations, but it is not easy. It requires adding external feedback devices and electrical controls on the valves that regulate the flow of the hydraulic fluid. It also increases costs and variability on a system that is already complicated and space-consuming.

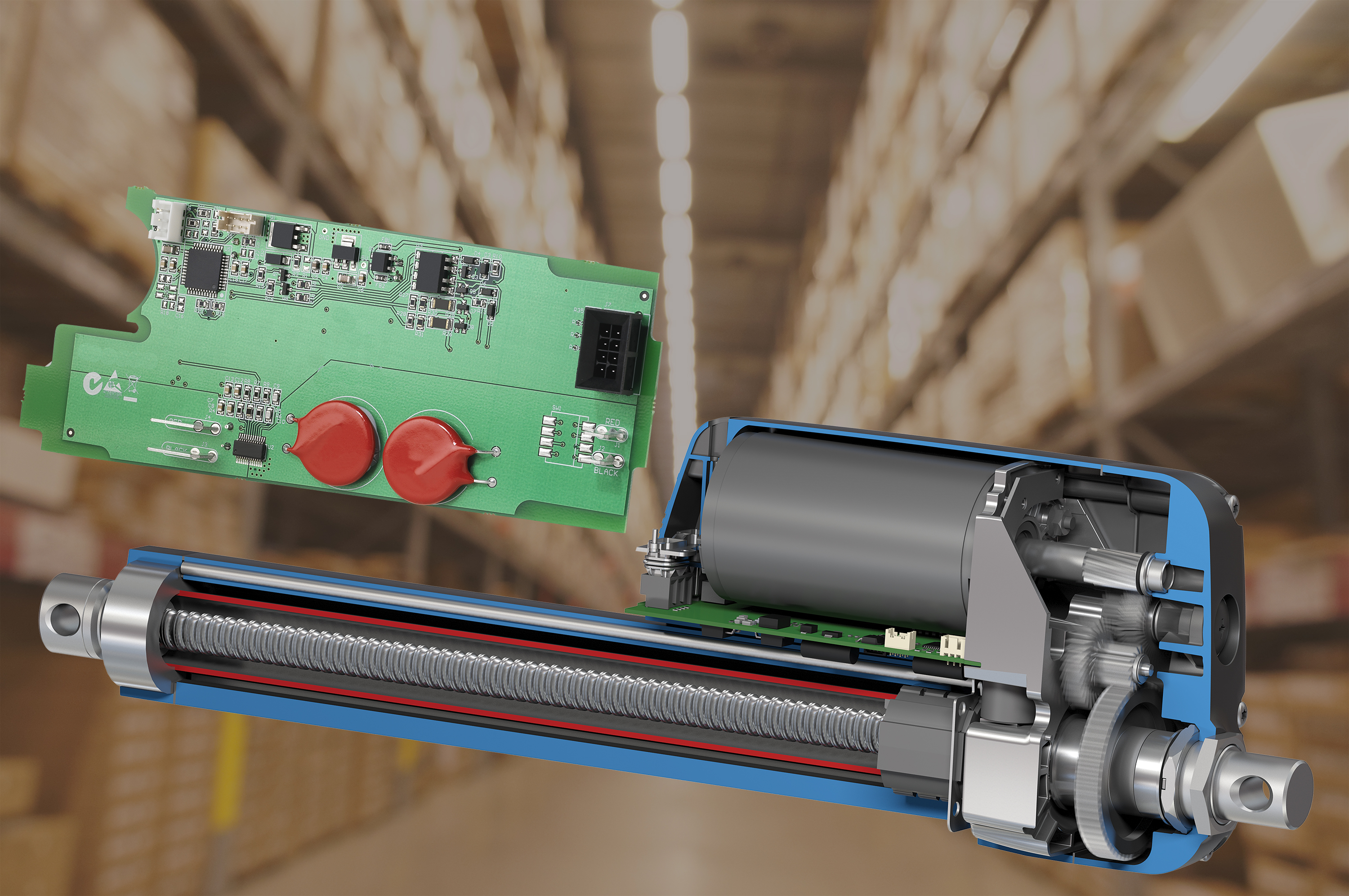

For applications requiring precision and control for loads up to 4000 lbs. (16 kN) of force, however, an electric actuator is a far more suitable technology choice. These smart actuators have changed the game by embedding microcomputer chips that provide precision and control without bolting on external devices. Switching, position feedback and system diagnostics are now done with software. (Figure 3)

Figure 3: Smart actuators integrate electronics within the actuator housing, which enable switching, synchronization and networking to be managed automatically based on signals from a common external source, such as a programmable logic controller (PLC).

Multiple devices can be networked, synchronized and managed automatically based on signals from a common external source, such as programmable logic controllers (PLCs) or other control units. Participation in more complex automation schemes becomes feasible, and a more compact system footprint simplifies operation and lowers the cost of ownership.

Will electric actuators be your savior?

Applications requiring more than 4800 lbs. of force will most likely need fluid-driven cylinders but maybe not on all axes. Just because there is already a hydraulic fluid reservoir for the braking system of an agricultural combine, for example, doesn’t mean that stringing tubes and cables throughout the vehicle is the most cost-effective solution.

As a rule, always consider electric actuators for any application requiring up to 4800 lbs. of force. This is especially true where space is at a premium, where the messiness of hydraulic fluids could be an issue, where eliminating long-term maintenance costs is desirable, and where machines are intended to last for 25 years or more.

For applications requiring up to 4000 lbs. with any level of precision or control, compare the costs and benefits of electric systems against hydraulic systems over their entire lifecycle. The more axes of motion involved, the more cost, and electric actuators are more likely to save you in the long run.

However, for most applications when you factor in the cost of implementing the support infrastructure, maintaining it over time, dealing with fluid leaks, and many of the other drawbacks associated with hydraulic cylinders, the total cost of ownership for electric actuators is comparable and sometimes lower. And when you factor in the need for greater control and precision, the potential for an even bigger return is much higher.