Mike Chipchase, Product Line Specialist for Linear Components Group at Thomson in Europe.

www.thomsonlinear.com thomson@thomsonlinear.com

A properly selected lubricant minimises friction, reduces torque, increases a screw’s efficiency, and extends life. Lubricants maintain the low friction advantage of ball screw assemblies by minimising rolling resistance between balls and grooves and sliding friction between adjacent balls.

A ball screw assembly must be thoroughly cleaned to remove all contaminants before lubrication and re-lubrication. Contamination is a leading cause of premature failure of ball screws. Proper lubrication helps keep most contaminants out, greatly reducing the damage they can cause. Rust preventative oil used for shipping and storage of the components should be wiped clean before application of the final lubrication.

Lubricants are often taken for granted, but the right choice for each application ensures a ball screw that performs properly for its calculated life. Both oil and grease provide corrosion protection, but lubricant choice depends on evaluation of the advantages and disadvantages of each in the given application.

You can apply oil at a controlled flow rate directly to the point of need, and it will clean out moisture and other contaminants as it runs through the ball nut. It can also provide cooling. Disadvantages include:

- Possibility of excess oil contaminating the process, such as mixing with the cutting fluid in machining applications.

- Cost of pump and metering system to apply oil properly.

Grease is less expensive than oil to apply, requires less frequent application and it does not contaminate process fluids. However:

- Grease is hard to keep inside the ball nut and has a tendency to build up at the ends of ball nut travel, where it accumulates chips and abrasive particles.

- Incompatibility of old grease with re-lubrication grease can create a problem. Be sure to check compatibility.

Grease Lubrication

Ball screws must be lubricated to operate properly to achieve the rated life. Greases can be applied directly to the screw threads near the root of the ball track or pumped into the ball nut if lube holes are provided.

Synthetic greases offer many performance advantages over mineral-based lubricants. They function over wider temperature ranges, offer greater stability and retain the viscosity needed to provide an adequate film thickness through a specified range of operating temperatures, speeds and loads.

Special additives can improve the grease’s ability to resist contaminants, reduce wear in the presence of load and vibration, reduce friction, decrease noise and increase load capacity. Do not use greases with graphite or molybdenum disulfide as these provide too low friction which promotes ball skid and interferes with the rolling process of the ball bearings.

Specialty greases are also available which include but are not limited to vacuum grade, food grade, clean room, and extreme temperatures. Match the grease selection to the application environment and then select based on performance requirements.

Precision ground ball screws, with precise motion and smooth, quiet operation, can also take advantage of filtration technology. Additional filtration results in cleaner lubricants, improved homogeneity of the thickening agent and removal of virtually all particulate matter.

One problem with grease: It tends to be fed out of the nut and onto the ball screw, accumulating at the extremities of travel where it collects contaminants. It must be replenished regularly and any excess removed leaving only a thin film of lubrication on the screw shaft at all times.

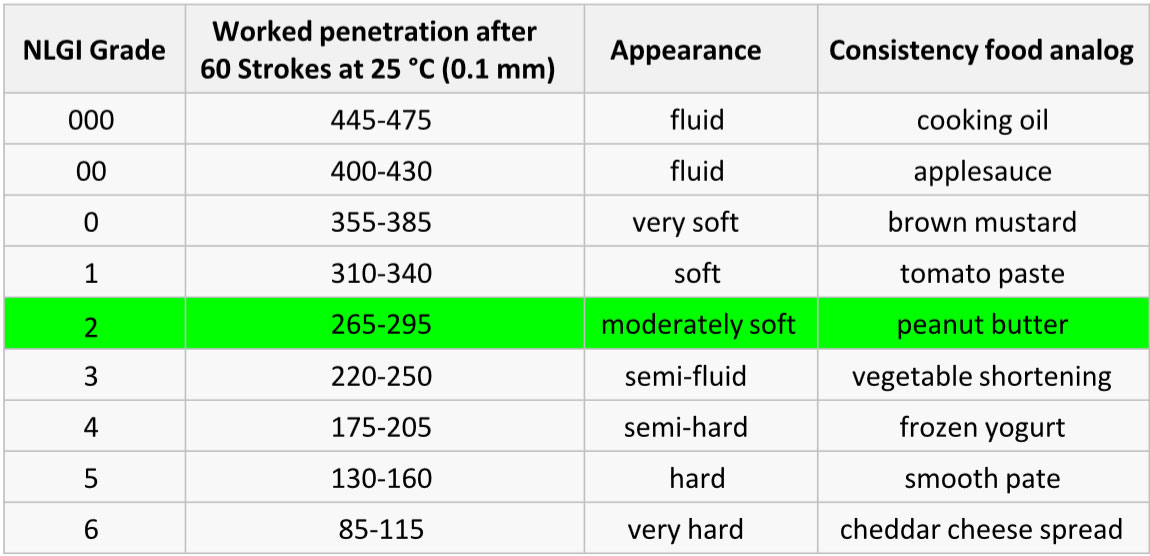

Greases consist of mineral or synthetic oil, additives, and a thickening agent such as lithium, bentonite, aluminum, and barium complexes. NLGI (National Lubricating Grease Institute) Grade is a widely used classification for lubricating greases. Greases are classified in one of nine grades based on their consistency. NLGI Grade alone is not sufficient for specifying grease for a particular application but is a useful qualitative measure.

The following table shows the NLGI grades and the worked penetration ranges:

Figure 1 - NLGI Grade

NLGI Grades 000 to 1 are used in applications requiring low viscous friction. Grades 0, 1 and 2 are used in highly loaded gearing. Grades 1 through 4 are often used in rolling contact bearings where Grade 2 is the most common. Lower numbers are softer and flow better, while higher numbers are firmer, tend to stay in place, and are a good choice when leakage is a concern. The table above compares the most common NLGI grades with household products that have similar consistencies.

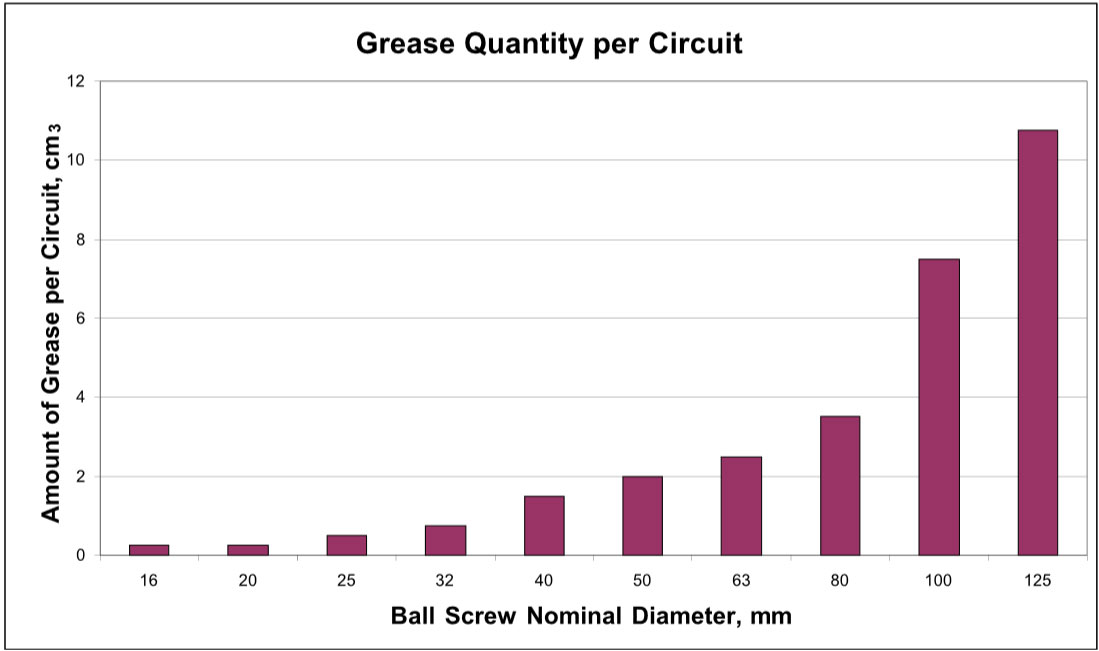

The guide to grease quantity per circuit, Figure 2, shows the recommended quantity in cm3 per ball circuit in the nut as a function of nominal ball screw diameter.

Figure 2 - Guide to grease quantity per circuit. To determine total volume required, you must

multiply the volume determined from this figure by the number of circuits in the ball nut.

As a rule of thumb, replenish grease at least every 600-800 hours. However, because conditions vary so widely, you should confirm this interval by inspection and readjust if needed. For extreme conditions, consult a lubrication expert or ball screw manufacturer.

All ball screw assemblies should be run smoothly throughout the entire stroke. If the torque is not uniform over the entire stroke:

- Visually inspect the screw shaft for accumulations of foreign contaminants.

- Using cleaning fluid or solvent, remove dirt from the ball grooves. Be sure to flush the ball nut assembly thoroughly.

- Cycle the ball nut along the screw shaft several times. Wipe with a dry, lint-free cloth and lubricate immediately.

Conclusion:

BALL SCREWS SHOULD NEVER BE RUN WITHOUT LUBRICATION!

The right oil or grease lubrication for ball screw assemblies reduces unscheduled downtime for repair by ensuring that the assemblies deliver their expected service life.