Choose Your Login Account

Thomson currently has two account systems - one for the website and CAD model downloads, and one for e-commerce. We understand that two logins is an inconvenience and are working to consolidate our systems into one login process. Until we’re able to consolidate the two logins, please follow these guidelines:

- Download CAD models

- Save and retrieve projects in LinearMotioneering® and MicronMotioneering® tools

- Access Distributor Extranet and all related resources

- Order directly from Thomson online (North America only)

- Authorized Thomson Distributors can view and order from quotes online (Global)

- View the shopping cart and look up prior direct orders

Customer Service Chat (ONLINE) Customer Service Chat (OFFLINE)

Linear Actuators

For more than 50 years, Thomson has pioneered the development of advanced electric linear actuators, delivering efficient, long-life and value-driven solutions to countless applications. Browse the many resources below to discover which actuator is ideal for your next linear motion project.

Thinking of converting from hydraulic to electric? Connect with a Thomson actuator product manager to learn more.

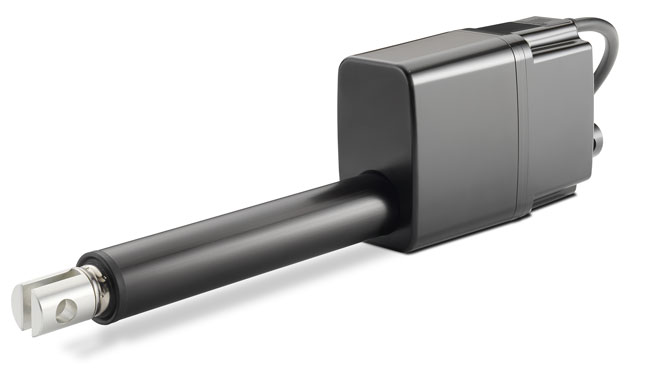

Electrak® XD

The next evolution of electric actuators has arrived. Loads up to 25,000 N. Duty cycle up to 100%. Smart control.

Standard Linear Actuators

Electrak XD Linear Actuators

Electrak HD Linear Actuators

Electrak MD Linear Actuators

Electrak LL Linear Actuators

H-Track Electro-Hydraulic Linear Actuators

Electrak 050 Linear Actuators

Electrak 1 (SP) Linear Actuators

M-Track

Electrak GX Linear Actuators

B-Track

Electrak LA14 Linear Actuators

Electrak PPA-DC Linear Actuators

Electrak Throttle Linear Actuators

Electrak 205 AC Linear Actuators

Electrak LA 24 AC Linear Actuators

Electrak PPA-AC Linear Actuators

Electrak PPA-M Non-Driven Linear Actuators

Electrak FA14 Non-Driven Linear Actuators

Max Jac Heavy Duty Linear Actuators

Electrak Non-Driven

LM80 Rodless Linear Actuators

Rotary Actuators

Linear Actuator Controls

Warner Linear Actuators

Legacy Linear Actuators

Custom Linear Actuator Options

Optimize your design with a custom linear actuator solution.

What Are Linear Actuators?

Electric linear actuators, which convert rotary motion of gears and a ball or lead screw into linear motion, provide a cleaner, safer, more efficient and cost-effective alternative to hydraulic or pneumatic solutions. Incorporating linear actuators into machines eliminates the risks involved with workers being put into dangerous situations, while turning tedious manual processes into automated ones.

What are linear actuators used for?

A linear actuator is a mechanical device designed to convert rotational motion into linear motion. It is used to move or control objects along a straight line. With their ability to provide precise and controlled movement, linear actuators play a vital role in improving efficiency, automation and convenience in a wide range of industries. They are utilized in industrial automation, material handling, automotive systems, aerospace technology and even in everyday consumer products.

How does a linear actuator work?

A linear actuator usually consists of an electric motor, a lead screw, and a nut or carriage. When the motor rotates, it transfers the rotational motion to the screw, causing the nut or carriage to move along the screw. This linear displacement allows the actuator to extend or retract, depending on the rotation direction of the motor. This allows the actuator to provide precise and controlled linear motion for various applications in industries like automation and automotive systems.

How do I choose the right linear actuator?

Choosing the linear actuator that best fits the requirements of your application involves several key factors:

- Load Capacity - Determine the load capacity and force required to move your application.

- Speed/Distance - Consider the speed and travel distance needed, as well as any space limitations.

- Power Source - Evaluate the power source options, such as AC or DC, and the voltage requirements.

- Control - Determine the desired control options, whether manual or automated.

- Environment - Assess the environmental conditions, such as temperature and moisture level, to ensure the durability of the chosen actuator.

Why Thomson Linear Actuators?

For more than 50 years and in various applications such as agricultural machines, material handling, medical devices, factory automation among others, powerful Thomson electric linear actuators have set the standard for long-life, heavy duty performance. Built from rugged, high-quality components, these 24v and 12v linear actuators require zero maintenance, don’t leak fluids and are simple to integrate into existing automation processes. Our “smart” heavy duty linear actuators have been integrated with a printed circuit board to provide advanced control options and enhanced performance.

Optimize your design with a custom electric linear actuator.

When our wide selection of linear actuators simply doesn’t meet your application requirements, experienced Thomson engineers can work with you to customize your actuator to meet your exact specifications. Options for your custom solution can include enhanced controllability, synchronization capabilities, stroke length, voltage, bus communication and many others.

Where Can You Get Started?

Thomson provides extensive online resources to help you no matter where you may be in the purchase decision process:

Let Thomson Help You Make Your Selection!

Linear Actuator Videos

Browse our latest videos on linear actuators, ranging from smart actuation, electro-hydraulic linear actuators, and more.

Clean and Simple: The Electrification of Linear Actuator Applications

VIDEO: Electrak XD: Ushering in the Next Evolution of Electric Actuators

Meet the Thomson Electrak® XD electric linear actuator. It is strong enough to take on new hydraulic applications while, at the same time, be smarter, smaller and more efficient than competitive technologies. This model represents a new level of load-handling capability, tackling loads up to 25,000 N. Duty cycle up to 100%, strokes up to 1200 mm and speeds up to 75 mm/s highlight its performance. How can the XD revolutionize your next design project?

VIDEO: H-Track Electro-Hydraulic Linear Actuator: Handling Heavy Loads in Tight Spaces

Learn more about the Thomson H-Track electro-hydraulic actuator, which incorporates a patented fluid power design that provides high load capability for extreme duty use, a more compact pin to pin than other actuators of the same load capability, excellent ingress protection and corrosion resistance.

VIDEO: Thomson Smart Actuation: Designing Smart Machines with Smart Tools

What is smart actuation and how can your applications benefit from it? Hakan Persson, the Global Product Line Director for Actuators at Thomson, walks you through the makings of a smart electromechanical actuator, its integrated electronics, where it is best applied and three Thomson actuator families offering these solutions.

VIDEO: Electrak® HD Linear Actuators Boost the Design IQ for Tribine Harvester

Thomson Electrak® HD linear actuators have benefited Tribine Harvester's groundbreaking design. Implemented in the concaves around the rotor and grain bin extensions, these components were selected because of their communication across a CAN bus network, dynamic braking and many other smart features.

Thomson Electrak HD Linear Actuators - Strong. Smart. Sturdy.

Thomson Product Line Specialist, Travis Gilmer, and Electrical Engineer, Chris Jones, walk through the features of the Electrak HD and how it is stronger, smarter and sturdier than any linear actuator Thomson has developed to date. Onboard electronics can eliminate the need for standalone controls, higher power opens a wider range of hydraulic applications to electric conversion, and it meets the most extreme environmental acceptance tests

Electrak HD Linear Actuators Keep Spika Work Platforms in Sync

The synchronization option, available with Thomson Electrak HD linear actuators, enables Spika Design and Manufacturing to offer their customers work platforms with improved performance, functionality and safety.

Adding Even More Control and Power to Thomson Smart Linear Actuators

Linear Actuators Literature

Brochures

Catalogs

| Linear Actuators | 9795 KB | |

| Linear Actuators | 9799 KB | |

| Linear Actuators | 5661 KB | |

| Linear Actuators | 4558 KB | |

| M-Track Actuators | 792 KB | |

| Warner Linear Electric Actuators and Controls | 4971 KB | |

| Warner Linear Electric Actuators and Controls | 4997 KB | |

| Warner Linear Electric Actuators and Controls | 5028 KB | |

| Warner Linear Electric Actuators and Controls | 4992 KB | |

| Warner Linear H-Track Actuators | 2414 KB |

Manuals

Technical Articles

Certifications

Configuration Files

Talk to a Thomson expert about converting your maching designs to electric

Click Here

| Warner Linear Actuators | |||

| B-Track |  |

— | — |

| H-Track |  |

— | — |

| M-Track |  |

— | — |

| Electrak XD Linear Actuators | |||

| Electrak XD Linear Actuators |  |

— | — |

| Electrak HD Linear Actuators | |||

| Electrak HD Linear Actuators |  |

— | — |

| Electrak MD | |||

| Electrak MD |  |

— | — |

| Electrak LL | |||

| Electrak LL |  |

— | — |

| Electrak Throttle Linear Actuators | |||

| Electrak Throttle Linear Actuators |  |

— | — |

| Max Jac Heavy Duty Linear Actuators | |||

| MaxJac Linear Actuators |  |

— | — |

| DC Linear Actuators | |||

| Electrak 050 Linear Actuators |  |

— | — |

| Electrak LA14 Linear Actuators |  |

— | — |

| Electrak 1 Linear Actuators |  |

— | — |

| Electrak 1SP |  |

— | — |

| Electrak GX |  |

— | — |

| AC Linear Actuators | |||

| Electrak LA24 Linear Actuators |  |

— | — |

| Electrak 205 Linear Actuators |  |

— | — |

| Non-Driven Linear Actuators | |||

| Electrak FA14 Linear Actuators |  |

— | — |

| Rodless Units Linear Actuators (Loadmaster LM80) | |||

| Loadmaster LM80 |  |

— | — |

| Rotary Actuators | |||

| Rotary Actuators DGB |  |

— | — |

| Legacy Linear Actuators | |||

|

— | — | |

| Electrak Pro Linear Actuators |  |

— | — |

| Electrak 5 |  |

— | — |

| Electrak 10 |  |

— | — |

| WhisperTrak Linear Actuators |  |

— | — |

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].