Choose Your Login Account

Thomson currently has two account systems - one for the website and CAD model downloads, and one for e-commerce. We understand that two logins is an inconvenience and are working to consolidate our systems into one login process. Until we’re able to consolidate the two logins, please follow these guidelines:

- Download CAD models

- Save and retrieve projects in LinearMotioneering® and MicronMotioneering® tools

- Access Distributor Extranet and all related resources

- Order directly from Thomson online (North America only)

- Authorized Thomson Distributors can view and order from quotes online (Global)

- View the shopping cart and look up prior direct orders

Customer Service Chat (ONLINE) Customer Service Chat (OFFLINE)

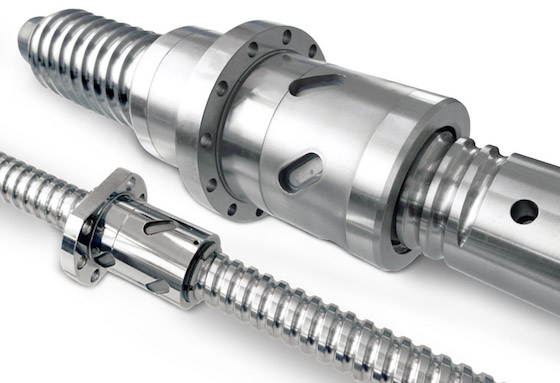

Ball Screws

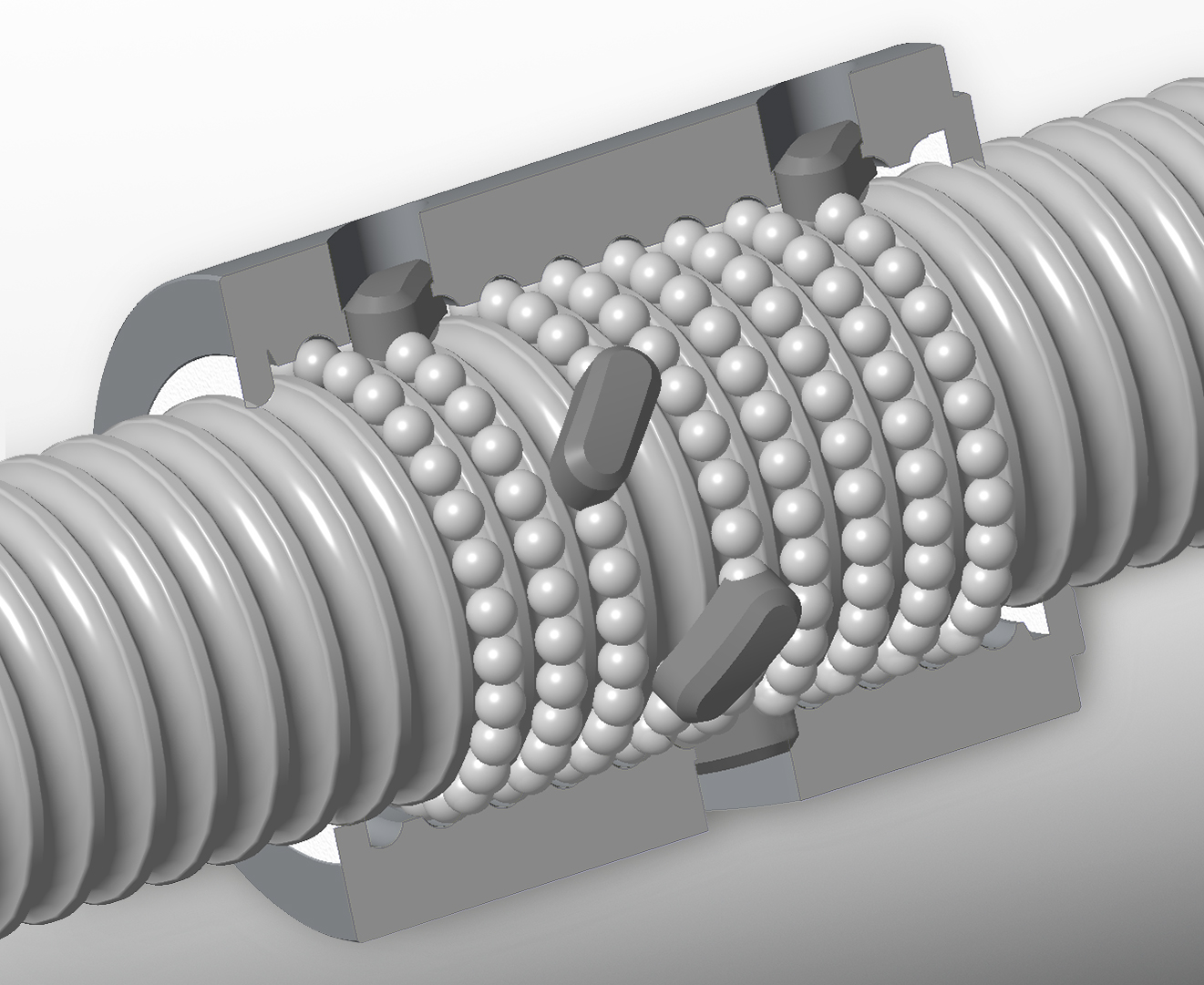

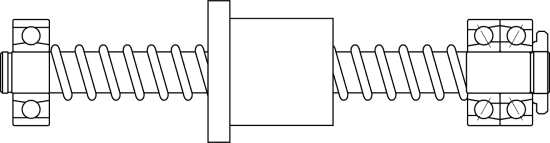

The ball screw drive is an assembly that converts rotary motion to linear motion (or vice versa). It consists of a ball screw and a ball nut packaged as an assembly with recirculating balls. The interface between the ball screw and the nut is made by balls which roll in matching ball forms. With rolling elements, the ball screw drive has a low friction coefficient (typically up to 98%). The forces transmitted are distributed over a large number of balls, giving a low relative load per ball comparatively.

Select A Solution

The Quicker, Simpler, Point & Click Method to Purchase an Individual Part or a Full Assembly

Sizing & Selecting Your System by Application Needs

Select by Part Number or Family Name

Contact Thomson with any needs you have

Need special machining? Contact Thomson

Select Product Type

Rolled Ball Screw/Nut Assembly

+/- 0.004 in per ft, 23 microns per 300 mm

Rolled Ball Nut

Flanged ball nut (left) and threaded ball nut (right).

Rolled Ball Screw

Standard ball screws feature smoother operation.

Ground Screw/Nut Assembly

+/- 0.0005 in per ft

Bearing Support

Mounting solutions for Thomson ball screw assemblies.

Low Load, Miniature

Up to 1,350 lbf (6 kN)

Mid Load, Standard

1,350 - 20,000 lbf (6 kN- 89 kN)

High Load, Large

>20,000 lbf (89 kN)

Flanged Nut

Includes either integrated or optional threaded flange.

Threaded Nut

These nuts come without a threaded flange but are capable of having threaded flanges added to the nut.

Cylindrical Nut

Compact, suitable for custom mounting.

Adjustable Preload

Adjustable Preload Ball Nut.

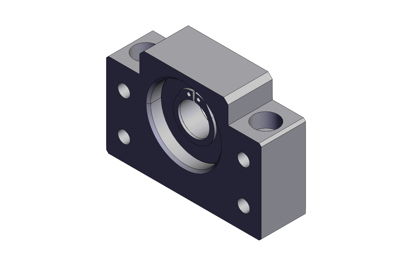

Fixed Support

Double bearing for driven end

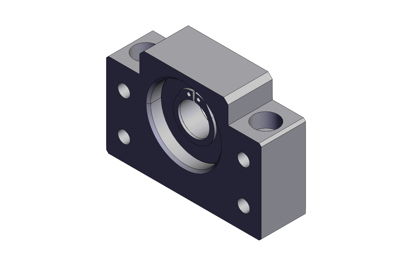

Floating (Simple) Support

Single bearing for support end

Motor Mount

Base mounted with flange mount, screw is machined, classified fixed

Threaded Nut Assembly

These nuts come without a threaded flange but are capable of having threaded flanges added to the nut.

How to mount

Threaded Nut Assembly

These nuts come without a threaded flange but are capable of having threaded flanges added to the nut.

How to mount

Threaded Nut Assembly

These nuts come without a threaded flange but are capable of having threaded flanges added to the nut.

How to mount

Top Mount Fixed Bearing Support

Base mounted, screw is machined, classified fixed

Flanged Fixed Bearing Support

Flange mounted, screw is machined, classified fixed

Universal Fixed Bearing Support

Flange or base mounted, screw is machined, classified fixed

Top Mount Floating Bearing Support

Base mounted, screw is machined, classified simple

Flanged Floating (Simple) Bearing Support

Flange mounted, screw is machined, classified simple

Universal Floating (Simple) Bearing Support

Flange or base mounted, screw is machined, classified simple

Selecting a Ball Screw Assembly for Your Application

A ball screw assembly is a mechanical device for translating rotational motion to linear motion. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The selection of the correct ball screw assembly for a specific application is an iterative process to determine the smallest envelope and most cost-effective solution. Below is a list of the most common (but not complete) design considerations used to select a ball screw assembly.

- Compression or Tension Load

- Linear Velocity

- Positional Accuracy and Repeatability

- Required Life Expectancy

- Mounting Configuration

- Dimensional Constraints

- Input Power Requirements

- Environmental Condition

At a minimum, the design load, linear velocity, and positional accuracy should be the known inputs and are used to calculate the diameter, lead, and load capacity of the ball screw assembly. Individual ball screw components are then selected based on life, dimensional constraints, mounting configuration, and environmental conditions.

How to mount

Assembly Configuration

STEP 1 - Move Profile

Enter Move Profile Parameters

| Motion Profile Output | Metric | Imperial |

|---|---|---|

| Max Speed | ||

| Acceleration | ||

| Average Speed | ||

| Move Time |

Move Profile

- Trapezoidal: Acceleration, constant speed, deceleration

- Triangular: Acceleration, deceleration

- Custom Multi-Segment: Create as many move profile segments as needed, define them individually

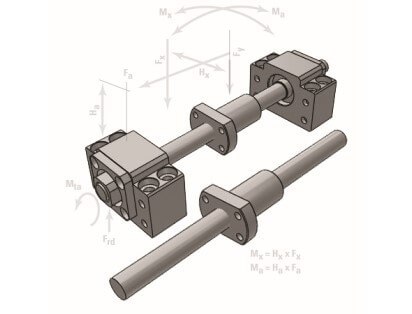

End Fixity Type

End fixity is the bearing configurations that are used to support the ends of a ball screw assembly. The 3 common end fixity configurations are shown. Fixed-free offers the least support where Fixed-Fixed offers the most support. Maximum screw RPM and buckling load are impacted by end fixity.

Move Profile Type

The Move profile will be broken up in either three equal time segments or equal distance segments (acceleration, constant speed, deceleration). For more customizability, see Custom Multi-Segment move profile option.

Threaded Length

Distance between the end supports (threaded length of the screw).

Move Distance

Full distance the nut will travel during the move. This distance does not have to be the full stroke.

STEP 2 - Application Data

Enter Load Forces

| Axial Forces Calculated | Metric | Imperial |

|---|---|---|

| Max Axial Force | ||

| Equivalent Operating Load | ||

| Force to Accelerate | ||

| Distance During Acceleration | ||

| Force at Constant Speed | ||

| Distance at Constant Speed | ||

| Force to Decelerate | ||

| Distance During Deceleration | ||

| Coefficent of Friction |

Direction of Travel

If the orientation of the screw is Horizontal to the ground or Vertical (perpendicular to the ground). For all other orientations, use Custom and the angle is measured from Horizontal.

Guide Bearing Type

Load is supported by the guide. The coefficient of friction is for the guide bearing system. In the example shown above, the load is supported by a profile rail (Ball) system.

For example, if you use a Ball Bushing, the friction is less than if you use a plain bearing. The lower the friction, the less force needed to move the load with the ball screw.

This frictional force is calculated using the formula: F = µ N

where

F is the frictional force

µ is the coefficient of friction

N is the normal force

If the application's guide bearing type is unknown, select Fluoronyliner from the dropdown. Since this bearing's coefficient of friction is the highest, this will build in a “worst case scenario” for the additional force required to drive the system.

Loading

Compression Load: A force that would tend to squeeze the screw in an axial direction.

Tension Load: A force in a direction that would tend to stretch the screw.

If Tension and Compression is selected, then Column Buckling will be calculated.

If Tension Only is selected, Column Buckling will not be calculated.

Mass of Load

Mass of Load = Mass of the item being moved.

The mass is used in calculating acceleration forces and frictional forces.

Axial Forces

In addition to the mass, this is an external force (if any) that is applied to the axial direction of the nut. Some segments can be zero force.

It is possible to define different segments of applied axial forces, depending on the application.

STEP 3 - Component Options

Select either cut ends, end machining only, or end machining with end supports

You must complete step 1 before selecting end supports.

| End Treatment Output | |

|---|---|

| End Fixity: | |

| Nut Direction: | |

| Extended Screw Direction: | |

| Left Support: | |

| Right Support: |

This tool allows you to configure machining for standard Thomson end supports. If special machining is required please contact Thomson.

Select Nut Style

The stated available nut options are based off your selections to this point. Refer to charts to the right.

Flanged Nut

667 Available

Includes either integrated or optional threaded flange.

Threaded Nut

249 Available

These nuts come without a threaded flange but are capable of having threaded flanges added to the nut.

Cylindrical Nut

222 Available

Compact, suitable for custom mounting.

Nut Availability Grid (Table updates as you progress through steps 1 to 3)

Test result codes are based the inputs at left, identifying which diameters and leads meet your application criteria. You may need to adjust the inputs to best tailor the results, i.e. reduce required speed to increase the footprint of successful screw diameter and lead combinations.

Click any cell in the availability grid for more information.

| Nominal Ball Screw Diameter (in) | Lead (in) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.125 | 0.200 | 0.250 | 0.413 | 0.473 | 0.500 | 0.660 | 1.000 | 1.500 | 1.875 | 2.000 | |

| 0.375 | |||||||||||

| 0.500 | |||||||||||

| 0.631 | |||||||||||

| 0.750 | |||||||||||

| 0.875 | |||||||||||

| 1.000 | |||||||||||

| 1.150 | |||||||||||

| 1.171 | |||||||||||

| 1.500 | |||||||||||

| 2.000 | |||||||||||

| 2.250 | |||||||||||

| 2.500 | |||||||||||

| 3.000 | |||||||||||

| 4.000 | |||||||||||

| Nominal Ball Screw Diameter (mm) | Lead (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 3 | 4 | 5 | 10 | 20 | 25 | 32 | 40 | 50 | |

| 10 | ||||||||||

| 12 | ||||||||||

| 16 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 32 | ||||||||||

| 40 | ||||||||||

| 50 | ||||||||||

| 63 | ||||||||||

| 80 | ||||||||||

| Chart Key | |

|---|---|

| Passes tests | Dynamic load failure |

| OAL length failure | Buckling failure (if compression selected) |

| Speed failure | Selected end supports not available |

| End support load failure | Not available in this diameter and lead |

| Thomson end supports available | |

All colors (other than the dark gray) are available nuts.

Of the available nuts, all colors but green indicate nuts that will cause a percent of failure.

Thomson Imperial Product Line

Thomson Imperial product line offers inch-dimensioned precision rolled ball screws available in a full range of diameter/lead combinations. Imperial ball nuts include external return systems available either non-preloaded or double-nut preloaded.

The product availability chart identifies diameter/lead assemblies available that meet the specifications/profile entered. See the chart key for product availability and reason if a product does not meet requirements.

Thomson Metric Product Line

Thomson Metric product line offer P5 accuracy precision rolled ball screws. Metric ball nuts include internal return systems for quieter and smoother operation.

The product availability chart identifies diameter/lead assemblies available that meet the specifications/profile entered. See the chart key for product availability and reason if a product does not meet requirements.

Chart Key

For colors other than green, it is possible that multiple colors will be in a box defining multiple failure reasons.

Save Your Project

End Support Selection

Selecting End Supports (3 Step Process)

Step 1

What is the difference between these options?

view more

Step 2

Next select between ending the screw at the end supports or continuing the screw through the end supports for either or both ends.

What is the difference between these options?

view more

Step 3

Lastly, CLICK on the two buttons below to select the end supports you wish to have added to your assembly on the right.

Not sure what the differences between the end supports are, or need more information on any particular end support? view more

All relevant part numbers in the proceeding solution table will reflect the same end support choices to allow easy price comparison.

End Support Types

For most applications, the ball screw ends(s) will be supported with a bearing. Configurations that are commonly used to support the ends of a ball screw are:

- A pair of back-to-back (fixed support)

- A deep groove radial bearing (floating or simple support)

Three combinations of bearing supports are typically used. Fixed on one end and free on the other offers the least support where Fixed on both ends offers the most support. Screws with more support are able to support higher loads without buckling and obtain higher critical speeds.

Nut Directions

In a screw that is asymmetrical, or one end is different than another like in a fixed free or fixed floating combination, when installing the nut the factory needs to know how to orient the nut. If the screw is symmetrical, or the same on both sides, feel free to select the default (Right).

End Support Machining

To fit a bearing support to a ball screw, a bearing journal must first be machined into the screw. The maximum diameter of the journal is limited by the screw geometry. Enough of the screw must be machined away to provide a shoulder for the bearing to seat against. The recommended maximum journal diameter is usually near the ball screws root diameter.

Example machined end (top) and machined end with a bearing block installed (Bottom)

To attach a ball screw to a drive system, a drive extension is machined into the screw. When ordering a ball screw assembly with bearing blocks or a ball screw with standard end machining, it is important to specify if this drive extension is wanted on one or both ends. The shaded area in the diagram above represents the drive extension. See the specific end machining details in the product catalog or specifications on the web.

End Support Selection

BK and BF: Base mounting configuration.

FK and FF: Flange mounting configuration.

MK: MK is an FK bearing support with a motor mount bracket.

WK: Flange mounting configuration with higher load capacity bearings.

Standard Ball Screws

Precision Rolled Inch Ball Screws

Miniature Metric Precision Ball Screws

Precision Rolled Metric Ball Screws

Precision Plus Ground Metric Ball Screws

Bearing Supports

High-Load Ball Screws

Installation, Maintenance, Lubrication, and Repair

Ideal for high-precision, high-load applications, metric and inch ball screws are manufactured to the highest standards to translate rotational motion to linear motion with minimal internal friction.

Why Thomson Ball Screws?

Not all precision ball screws are created equal. At Thomson, our careful attention to design, quality, materials, manufacturing and application support has set us apart from the competition and created an ideal recipe for success that has lasted for decades.

Customization Options

When standard Thomson ball screws don’t meet your exact specification requirements, our engineering experts can help customize a solution for your application. Whether it’s one or a large quantity, a simple component modification or complex assembly, our custom capabilities can meet your needs and improve your machine’s performance.

Where Can You Get Started?

Thomson provides extensive online resources to help you no matter where you may be in the purchase decision process:

What Can Thomson Ball Screws Do For You?

VIDEO: Ball Screws: Design and Installation

This video provides an overview of the anatomy and installation of ball screws. It covers the function of ball screws in application design as well as the components of a ball screw assembly and of a ball nut. Also included is a demonstration of the installation of a ball nut onto a screw and the ball bearing insertion process in the event that some bearings fall out during installation.

VIDEO: Maximize Load Capacity, Lifecycle and Compactness of Your Linear Motion Designs

Any new application requires careful analysis of product performance, life and cost. Especially those that take on larger loads. Learn why you should be considering a high-load ball screw over standard ball screws for your next linear motion application.

Presenter: Markus Brändle, Product Line Specialist – Screws, Screw Jacks and LB&G Thomson Neff Industries, Germany

VIDEO: Tech Tips: How to Load Ball Bearings into a Metric Series Ball Nut

How to reload the bearings into a button return ball nut. Often Metric ball nuts are button return ball nuts. But this technique can also be used on tube return ball nuts.

VIDEO: Considerations and Calculations for Choosing the Right Ball Screw for Your Application

From all the thousands of possible choices, how can you quickly and confidently size and select the optimal ball screw solution for your linear motion application?

VIDEO: Tech Tips: How to Transfer a Ball Nut to a Ball Screw

How to install a ball nut onto a screw from an arbor.

Technical Articles

-

Inch vs. Metric Ball Screws: Are You Asking the Right Questions?

Because ball screws are available in both inch and metric dimensions, designers sometimes begin the specification process by selecting a product family based on the unit of measure. This decision may prematurely exclude the ideal product for the application and lead to significant losses in time, labor and expense. This article explains how sizing and selection questions centered on performance – instead of product monikers – can lead to more efficient linear motion designs.

Learn More -

High Load Ball Screws - The Motion Control Solution with Higher Load Density

Roller screws have been promoted as the only technology of choice for handling large loads when size is a constraint. But in actuality, advances in ball screw technology have now enabled the capability to support high-load applications as well. This is important because a high-load ball screw is typically less than half the cost of a comparable roller screw at equivalent performance points.

Learn More -

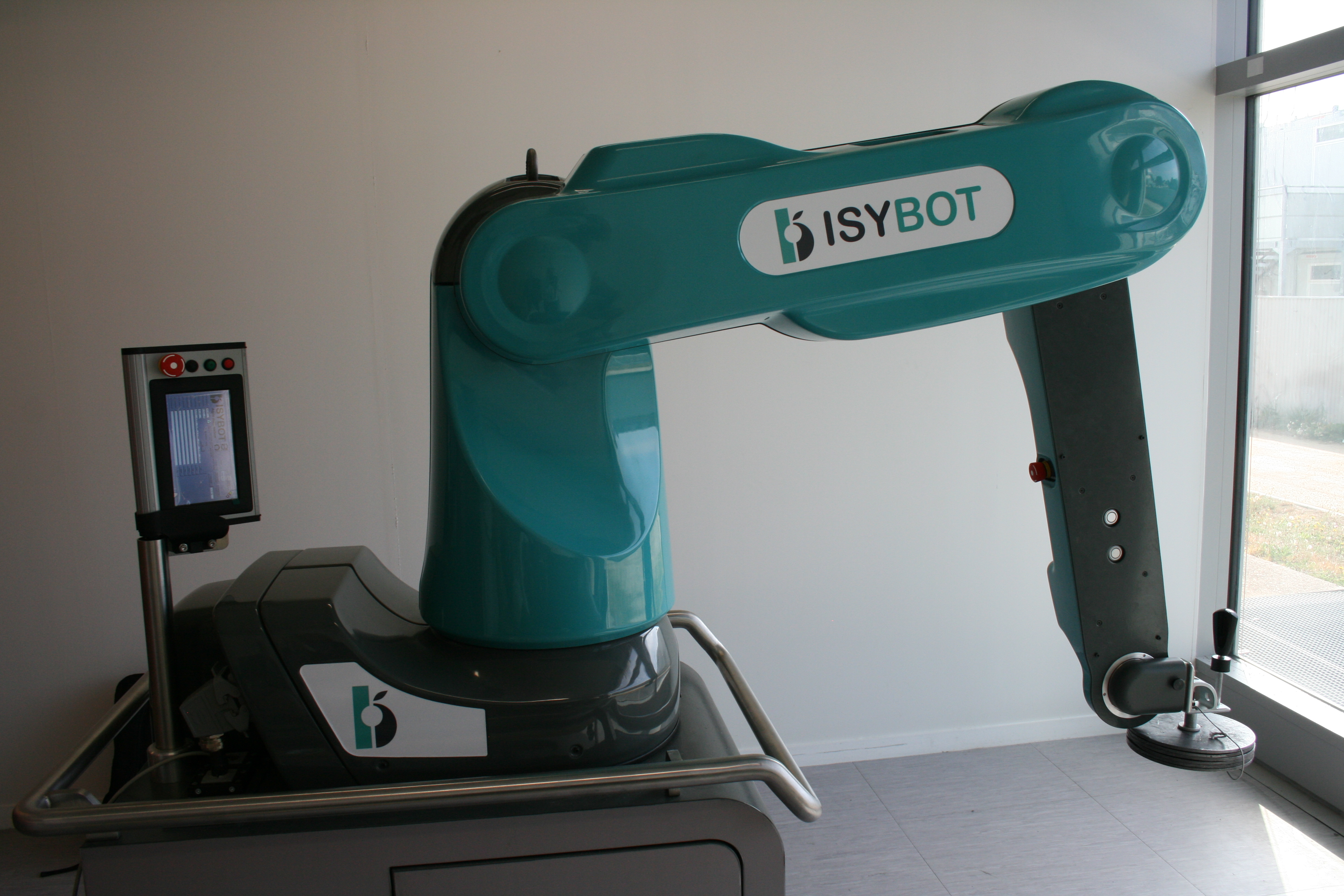

Ball Screws – An Answer to Safe and Efficient Motion for Cobots

Used in large-scale production applications that involve continuous lifting operations but still require a human touch, collaboration robots (cobots) are gaining popularity. A French cobot maker has developed a solution that uses ball screw and cable actuators instead of gears, setting a new benchmark for cobot efficiency and safety.

Learn More

Brochures

| Flanged Metric Precision Rolled Ball Screws (16 - 50 mm) | 756 KB | |

| Ball Screw Refurbishment Service in Europe | 693 KB | |

| Ball Screw Refurbishment Service in Europe | 694 KB | |

| High-Load Ball Screws | 395 KB | |

| High-Load Ball Screws | 370 KB | |

| High-Load Ball Screws | 391 KB | |

| Metric Precision Ball Screws (Made in Germany) | 1053 KB | |

| Metric Precision Ball Screws (Made in Germany) | 1062 KB | |

| Miniature Metric Ball Screws | 625 KB | |

| Miniature Metric Ball Screws | 655 KB | |

| Miniature Metric Ball Screws | 668 KB | |

| Miniature Components and Systems | 6871 KB | |

| Miniature Components and Systems | 6862 KB | |

| Miniature Components and Systems | 1603 KB | |

| SFM Safety Nut | 446 KB | |

| SFM Safety Nut | 442 KB |

Catalogs

Manuals

Technical Articles

Press Releases

| Thomson High-Load Ball Scews Provide Maximum Load Capacity and Longer Life in a Compact Envelope | 2019-02-04 |

Certifications

| + Ball Screw Assemblies | |||

| Ball Screw Assemblies - Inch |  |

— | — |

| Ball Screw Assemblies - Metric (North America) |  |

— | — |

| Ball Screw Assemblies - Metric (Europe) |  |

— | — |

| + Ball Nuts | |||

| Flanged Ball Nuts - Inch |  |

— | — |

| Flanged Ball Nuts - Metric |  |

— | — |

| Threaded Ball Nuts - Inch |  |

— | — |

| Threaded Ball Nuts - Metric |  |

— | — |

| Cylindrical Ball Nuts - Metric |  |

— | — |

| + End Supports | |||

| Ball Screws End Supports - Inch |  |

— | — |

| Ball Screw End Supports - Metric |  |

— | — |

| + Screws | |||

| Precision Rolled Ball Screws - Inch |  |

— | — |

| Precision Rolled Ball Screws - Metric |  |

— | — |

| + Accessories | |||

| Ball Screw Flanges |  |

— | — |

| Ball Screw Wipers |  |

— | — |

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].