Application. Design. Performance.

Thomson optimizes every step in the development of durable food-processing equipment.

Your engineering isn’t complete until you understand how Thomson can contribute to optimized motion in food-processing equipment. Thomson has decades of experience in supplying technologically superior components that allow application flexibility while pushing production efficiency. We also streamline the sourcing process for components that can be trusted for longevity, washability, corrosion-resistance and performance.

Thomson's Competitive Components:

1) Superior Products - We have the broadest selection and readily provide standard, modified standard, and full custom solutions.

- Linear bearings, shafting, and guides

- Ball and lead screws

- Linear slide tables and systems

- Linear and Precision Linear actuators

- True planetary gearheads

- Clutches and brakes

2) Superior Technology - Our products perform as promised and over-deliver on quality and longevity.

- Withstand caustic cleaning and demanding use without corrosion through use of 300-grade (303, 304, 316) stainless, UHMW coatings, Armalloy and many more options

- Provide 120 psi spray-rated washdown compliance

- Food-grade Lube-for-Life lubrication >

3) Unbiased Design Solutions - Our unmatched breadth of line encourages designs that don’t compromise - assured by our commitment to fully agnostic solutions. We have tremendous ability to test your application load and movement profiles to develop optimal solutions with over 60 years of experience in optimal, standard, modified-standard, and full custom designs.

- Zero-setup products for speed-to-market and cost effectiveness

- Electric actuator conversion from hydraulic or pneumatic

- Online sizing and selection tools

Integrate Our Expertise Into Your Design Process:

When experienced Thomson engineers contribute early in your design process, you optimize machine performance, life and cost. Leverage our capacity for analysis, modifications and white sheet solutions. Take advantage of smart standardization that gives you more freedom and improved speed to market. And then rest easy knowing that the results will be predictably excellent. Here are some of the keys:

- We Develop

Standard platforms that make any design easily customizable. - We Produce

Zero set-up products to get our clients to market faster and more cost-effectively. - We Test

Extensively on your equipment to enable evaluation of our products in your application.

Couple these process advancements with our highly proven, highly engineered components and pre-assembled systems, and you’ve optimized your food-processing machine project.

We Participate in a Wide Range of Applications:

- Accumulators

- Bag fillers

- Blenders

- Capsule fillers

- Choppers

- Conveyors

- Cookers

- Cup fillers

- Cutters

- Deboners

- Dumpers

- Elevators

- Extruders

- Fillers

- Form, fill and seal

- Heat exchanges

- Injectors

- Loaders

- Material handling/palletizers

- Meat processing

- Mixers

- Ovens

- Patty formers

- Pick and place

- Pouch machines

- Presses/cutters

- Scales

- Separators

- Slicers

Applications

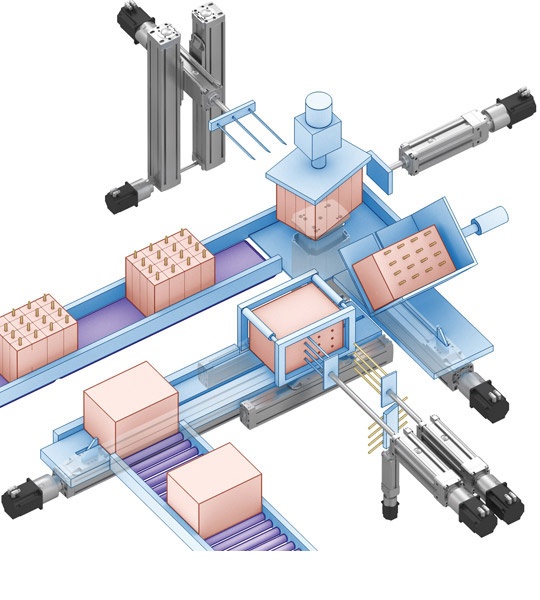

Bread Robot

Two-axis packaging robots do considerable work in assembling and packing food items like baked goods, boxed cereal, boxed dairy products and mincemeat in trays. The system involves...

Skewer/Assembly

Thomson’s components and solutions shine in high-throughput multi-axis applications such as assembly lines with skewers. Skewer units employ gearheads and clutches, brakes and reso...

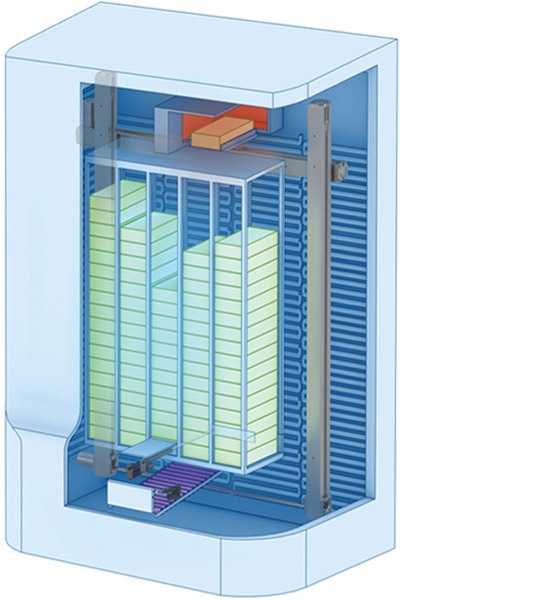

Food Vending Machine

Actuators of multiple sizes, ball screws, gearheads and full linear motion systems combine to control the multiple stages in this application, where frozen dinner boxes are placed...

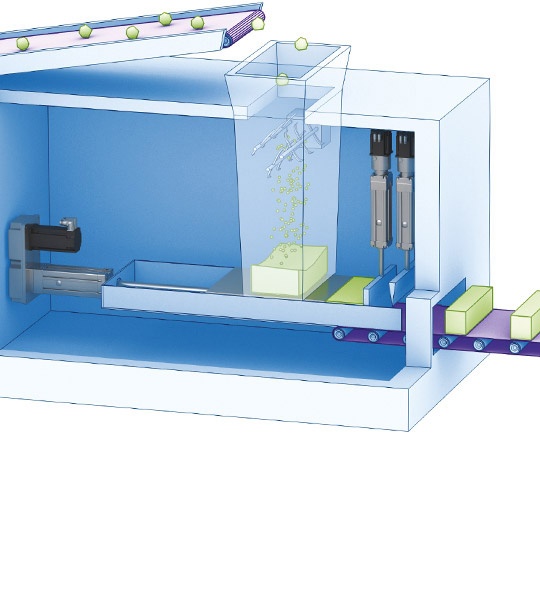

Food Press

Food press applications can employ numerous Thomson components and fully engineered solutions. The press mechanism can make use of a high-load rodded actuator with a friction break...

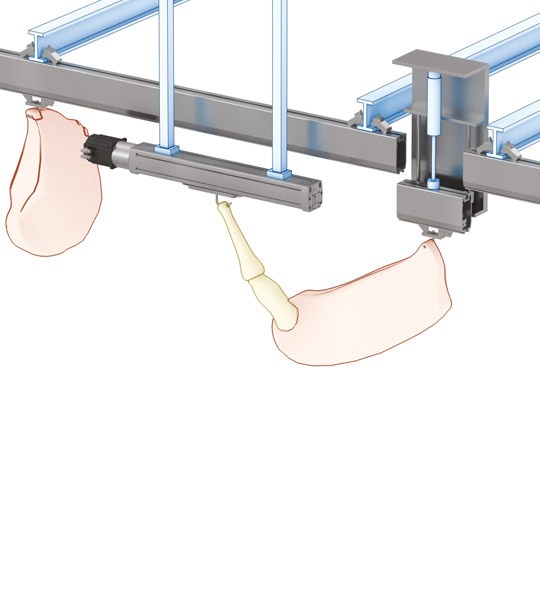

Deboner

These heavy-duty positioning machines promote safety by handling the hard work of positioning carcasses for deboning. In this application, round rail linear guides are employed in...