Choose Your Login Account

Thomson currently has two account systems - one for the website and CAD model downloads, and one for e-commerce. We understand that two logins is an inconvenience and are working to consolidate our systems into one login process. Until we’re able to consolidate the two logins, please follow these guidelines:

- Download CAD models

- Save and retrieve projects in LinearMotioneering® and MicronMotioneering® tools

- Access Distributor Extranet and all related resources

- Order directly from Thomson online (North America only)

- Authorized Thomson Distributors can view and order from quotes online (Global)

- View the shopping cart and look up prior direct orders

Customer Service Chat (ONLINE) Customer Service Chat (OFFLINE)

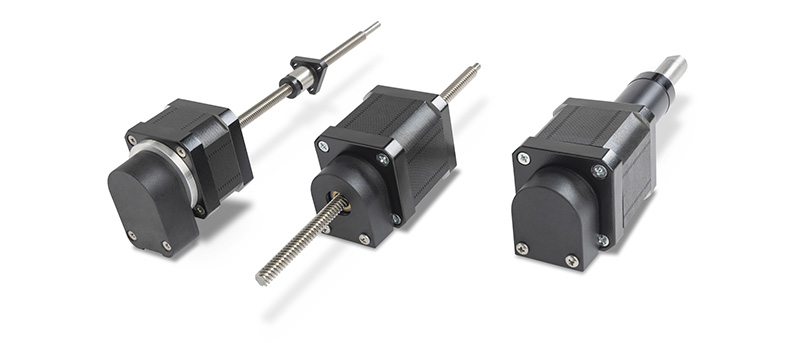

Stepper Motor Linear Actuators

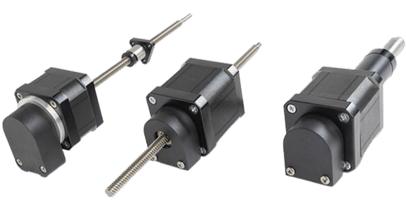

Thomson stepper motor linear actuators combine a hybrid stepper motor and a precision lead screw in one compact envelope. Our stepper motor linear actuators are now offered in three basic configurations – rotating screw (MLS), rotating nut (MLN) and actuator (MLA).

Select Product Type

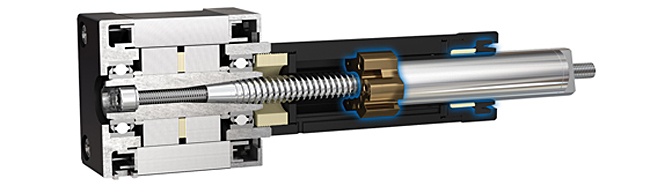

Motorized Lead Screw Actuators (MLA)

Fully housed configuration with integrated guidance and support for easy installation.

Rotating Screw Configuration (MLS)

Rotating screw and external nut configuration allowing for various motor, screw, and nut combinations.

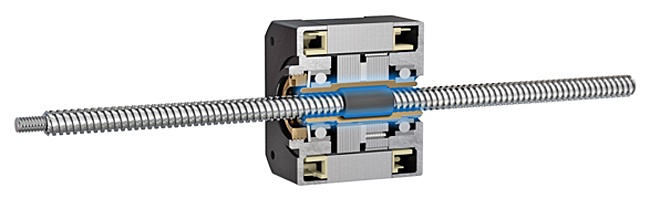

Rotating Nut Configuration (MLN)

Internal rotating nut configuration allowing for compactness and simplified motion.

NEMA 8

0.8” x 0.8” (20mm x 20mm) square face capable of loads up to 5 lbs (22 N)

NEMA 11

1.1” x 1.1” (28mm x 28mm) square face capable of loads up to 20 lbs (89 N)

NEMA 14

1.4” x 1.4” (35mm x 35mm) square face capable of loads up to 50 lbs (222 N)

NEMA 17

1.7” x 1.7” (42mm x 42mm) square face capable of loads up to 75 lbs (334 N)

NEMA 23

2.3” x 2.3” (57mm x 57mm) square face capable of loads up to 200 lbs (890 N)

No Preference

NEMA 8

0.8” x 0.8” (20mm x 20mm) square face capable of loads up to 5 lbs (22 N)

NEMA 11

1.1” x 1.1” (28mm x 28mm) square face capable of loads up to 20 lbs (89 N)

NEMA 14

1.4” x 1.4” (35mm x 35mm) square face capable of loads up to 50 lbs (222 N)

NEMA 17

1.7” x 1.7” (42mm x 42mm) square face capable of loads up to 75 lbs (334 N)

NEMA 23

2.3” x 2.3” (57mm x 57mm) square face capable of loads up to 200 lbs (890 N)

No Preference

NEMA 11

1.1” x 1.1” (28mm x 28mm) square face capable of loads up to 20 lbs (89 N)

NEMA 14

1.4” x 1.4” (35mm x 35mm) square face capable of loads up to 50 lbs (222 N)

NEMA 17

1.7” x 1.7” (42mm x 42mm) square face capable of loads up to 75 lbs (334 N)

NEMA 23

2.3” x 2.3” (57mm x 57mm) square face capable of loads up to 200 lbs (890 N)

No Preference

Standard Backlash Nut

Clearance between screw and nut of up to 0.010 in (0.25 mm).

Anti-Backlash Nut

Preloaded nuts with no play between the screw and nut.

Standard Backlash Nut

Clearance between screw and nut of up to 0.010 in (0.25 mm).

Anti-Backlash Nut

Preloaded nuts with no play between the screw and nut.

Standard Backlash Nut

Clearance between screw and nut of up to 0.010 in (0.25 mm).

Anti-Backlash Nut

Preloaded nuts with no play between the screw and nut.

Standard Backlash Nut

Clearance between screw and nut of up to 0.010 in (0.25 mm).

Anti-Backlash Nut

Preloaded nuts with no play between the screw and nut.

Standard Backlash Nut

Clearance between screw and nut of up to 0.010 in (0.25 mm).

Anti-Backlash Nut

Preloaded nuts with no play between the screw and nut.

Standard Backlash Nut

Clearance between screw and nut of up to 0.010 in (0.25 mm).

Anti-Backlash Nut

Preloaded nuts with no play between the screw and nut.

RSF

Compact nut in bearing grade Acetal with a triangular mounting flange.

RSFH

Compact nut in bearing grade high performance PEEK with a triangular mounting flange.

SN

Bearing grade Acetal nut with imperial (inch) mounting threads. *Metric thread mount lead nut available upon request.

MTS

Bearing grade Acetal nut with a triangular or round mounting flange.

XCMF

Miniature flange mount nut with high axial stiffness, low drag, active wear compensation, and design loads up 5 lbf (22 N). For 0.188 in, 0.250 in, 4 mm, and 6 mm lead screws only.

XCMT

Miniature imperial thread mount nut with high axial stiffness, low drag, active wear compensation, and design loads up to 5 lbf (22 N). For 0.188 in, 0.250 in, 4 mm, and 6 mm lead screws only.

SNAB

Customizable thread mount nut with a spring pre-load of up to 9 lbs (40 N).

RSF

Compact nut in bearing grade Acetal with a triangular mounting flange.

RSFH

Compact nut in bearing grade high performance PEEK with a triangular mounting flange.

SN

Bearing grade Acetal nut with imperial (inch) mounting threads. *Metric thread mount lead nut available upon request.

BN

Bearing grade bronze nut with imperial (inch) mounting threads.

MTS

Bearing grade Acetal nut with a triangular or round mounting flange.

XCF

Flange mount nut with high axial stiffness, low drag, and active wear compensation.

XCT

Imperial thread mount nut with high axial stiffness, low drag, and active wear compensation. *Metric thread mount lead nut available upon request.

XCMF

Miniature flange mount nut with high axial stiffness, low drag, active wear compensation, and design loads up 5 lbf (22 N). For 0.188 in, 0.250 in, 4 mm, and 6 mm lead screws only.

XCMT

Miniature imperial thread mount nut with high axial stiffness, low drag, active wear compensation, and design loads up to 5 lbf (22 N). For 0.188 in, 0.250 in, 4 mm, and 6 mm lead screws only.

AFT

Flange mount nut with a design loads of up to 25 lbs (111 N).

SNAB

Customizable thread mount nut with a spring pre-load of up to 9 lbs (40 N).

RSF

Compact nut in bearing grade Acetal with a triangular mounting flange.

RSFH

Compact nut in bearing grade high performance PEEK with a triangular mounting flange.

SN

Bearing grade Acetal nut with imperial (inch) mounting threads. *Metric thread mount lead nut available upon request.

BN

Bearing grade bronze nut with imperial (inch) mounting threads.

MTS

Bearing grade Acetal nut with a triangular or round mounting flange.

XCF

Flange mount nut with high axial stiffness, low drag, and active wear compensation.

XCT

Imperial thread mount nut with high axial stiffness, low drag, and active wear compensation. *Metric thread mount lead nut available upon request.

XCMF

Miniature flange mount nut with high axial stiffness, low drag, active wear compensation, and design loads up 5 lbf (22 N). For 0.188 in, 0.250 in, 4 mm, and 6 mm lead screws only.

XCMT

Miniature imperial thread mount nut with high axial stiffness, low drag, active wear compensation, and design loads up to 5 lbf (22 N). For 0.188 in, 0.250 in, 4 mm, and 6 mm lead screws only.

AFT

Flange mount nut with a design loads of up to 25 lbs (111 N).

SNAB

Customizable thread mount nut with a spring pre-load of up to 9 lbs (40 N).

RSF

Compact nut in bearing grade Acetal with a triangular mounting flange.

RSFH

Compact nut in bearing grade high performance PEEK with a triangular mounting flange.

SN

Bearing grade Acetal nut with imperial (inch) mounting threads. *Metric thread mount lead nut available upon request.

BN

Bearing grade bronze nut with imperial (inch) mounting threads.

MTS

Bearing grade Acetal nut with a triangular or round mounting flange.

XCF

Flange mount nut with high axial stiffness, low drag, and active wear compensation.

XCT

Imperial thread mount nut with high axial stiffness, low drag, and active wear compensation. *Metric thread mount lead nut available upon request.

XCMF

Miniature flange mount nut with high axial stiffness, low drag, active wear compensation, and design loads up 5 lbf (22 N). For 0.188 in, 0.250 in, 4 mm, and 6 mm lead screws only.

XCMT

Miniature imperial thread mount nut with high axial stiffness, low drag, active wear compensation, and design loads up to 5 lbf (22 N). For 0.188 in, 0.250 in, 4 mm, and 6 mm lead screws only.

AFT

Flange mount nut with a design loads of up to 25 lbs (111 N).

SNAB

Customizable thread mount nut with a spring pre-load of up to 9 lbs (40 N).

RSF

Compact nut in bearing grade Acetal with a triangular mounting flange.

RSFH

Compact nut in bearing grade high performance PEEK with a triangular mounting flange.

SN

Bearing grade Acetal nut with imperial (inch) mounting threads. *Metric thread mount lead nut available upon request.

BN

Bearing grade bronze nut with imperial (inch) mounting threads.

MTS

Bearing grade Acetal nut with a triangular or round mounting flange.

XCF

Flange mount nut with high axial stiffness, low drag, and active wear compensation.

XCT

Imperial thread mount nut with high axial stiffness, low drag, and active wear compensation. *Metric thread mount lead nut available upon request.

AFT

Flange mount nut with a design loads of up to 25 lbs (111 N).

SNAB

Customizable thread mount nut with a spring pre-load of up to 9 lbs (40 N).

RSF

Compact nut in bearing grade Acetal with a triangular mounting flange.

RSFH

Compact nut in bearing grade high performance PEEK with a triangular mounting flange.

SN

Bearing grade Acetal nut with imperial (inch) mounting threads. *Metric thread mount lead nut available upon request.

BN

Bearing grade bronze nut with imperial (inch) mounting threads.

MTS

Bearing grade Acetal nut with a triangular or round mounting flange.

XCF

Flange mount nut with high axial stiffness, low drag, and active wear compensation.

XCT

Imperial thread mount nut with high axial stiffness, low drag, and active wear compensation. *Metric thread mount lead nut available upon request.

XCMF

Miniature flange mount nut with high axial stiffness, low drag, active wear compensation, and design loads up 5 lbf (22 N). For 0.188 in, 0.250 in, 4 mm, and 6 mm lead screws only.

XCMT

Miniature imperial thread mount nut with high axial stiffness, low drag, active wear compensation, and design loads up to 5 lbf (22 N). For 0.188 in, 0.250 in, 4 mm, and 6 mm lead screws only.

AFT

Flange mount nut with a design loads of up to 25 lbs (111 N).

SNAB

Customizable thread mount nut with a spring pre-load of up to 9 lbs (40 N).

Design, Installation and Maintenance Notes

1.

Select Stepper Motor Linear Actuator Configuration

Determine which of the configurations – rotating screw (MLS), rotating nut (MLN) or actuator (MLA) – the application requires. Click here for application examples.

2.

Select Motor Size

Select the appropriate size based on desired performance, motor frame size, etc. Thomson offers five base models (MLxX8, MLx11, MLx14, MLx17 and MLx23) in various motor windings, linear travels and load capacities.

3.

Select Lead Screw Configuration and End Machining or End Mounting

For MLS or MLN, select the lead screw diameter and length with regard to the required stroke of the application and the type of end machining the screw requires. For MLA, select desired lead or travel per step, stroke length and end mounting.

4.

Select Nut

For rotating screw (MLS) configurations, choose between various nut mounting styles, materials, and backlash options. Rotating nut (MLN) configurations as default always come in a high performance material, standard backlash nut. As a default, all MLA configurations come with a standard backlash and performance material nut.

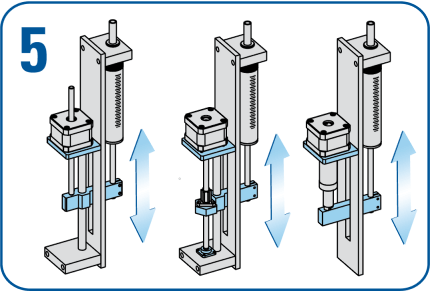

5.

Mount the Stepper Motor Linear Actuator

Mount the unit into your assembly. For MLA, use the end mounting installation guidelines shown below.

MLA End Mounting Installation

When installing your load to the end mount of an MLA assembly, always use the dedicated flats shown below to prevent over-torquing and damaging the actuator‘s internal components.

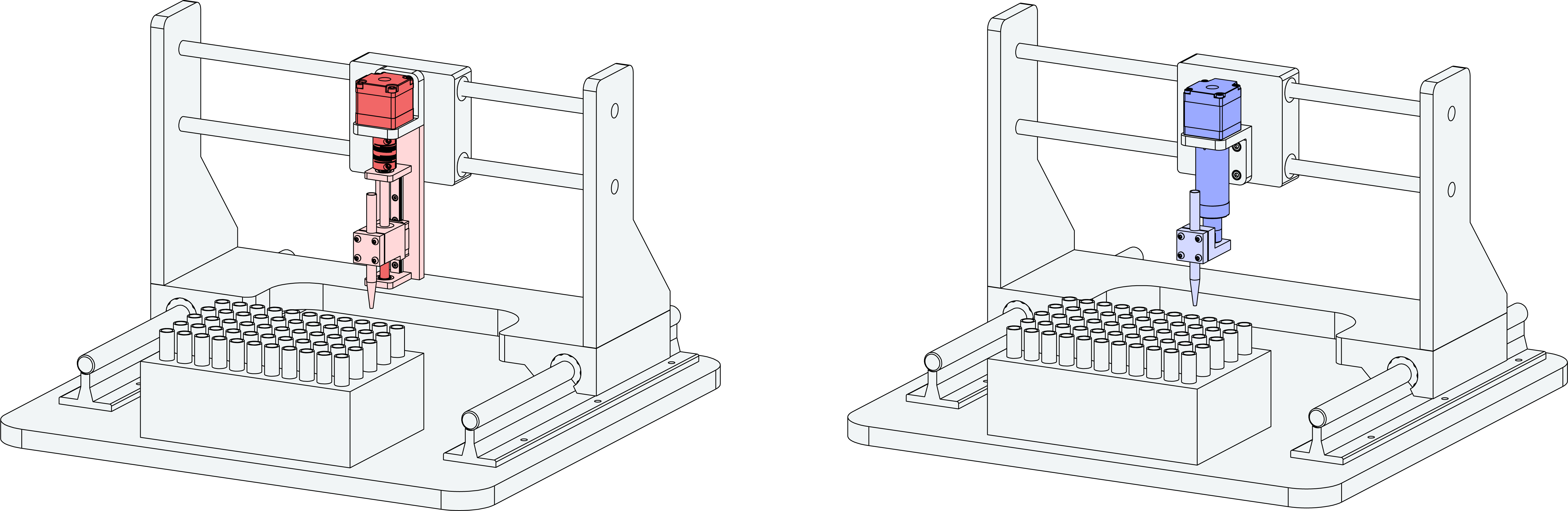

Examples of Applications

MLA

Pipetting

Plate Vertical Positioning

Monitor Tilting

MLS

Pipetting

XY Stages

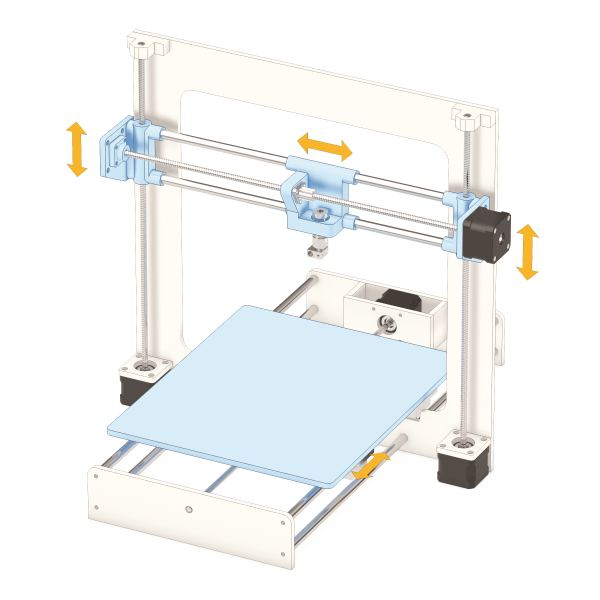

3D Printing

Fluid Pumps

MLN

Robotic Gripper

Horizontal Positioning

Fluid Pumps

Encoder

Error

Standard Stepper Motor Linear Actuators

Actuator (MLA)

MLAs are a fully housed solution in which the motion is taken care of for you - simply determine stroke length, linear travel per step or revolution, and precision level to select an appropriate model.

Rotating Screw (MLS)

MLS assemblies actuate by having the stepper motor rotate a lead screw and translate a load that is attached to the lead nut.

Rotating Nut (MLN)

MLN assemblies actuate by rotating a nut within the stepper motor body. Motion is achieved by constraining the motor and translating a load attached to the lead screw or constraining the lead screw and translating a load attached to the stepper motor.

Rotary Encoders Available as a Standard Option

Rotary Encoders deliver real-time feedback about position, speed, direction and many other useful motion parameters.

Thomson offers pre-assembled encoders as a standard option on all stepper motor linear actuators.

Custom Stepper Motor Linear Actuator Options

Optimize your design with a custom stepper motor linear actuator solution.

Why Thomson Stepper Motor Linear Actuators?

Thomson offers three basic configurations – rotating screw (MLS), rotating nut (MLN) and actuator (MLA). The open architecture rotating screw and rotating nut motorized lead screws suit applications where external guidance is present or a high level of design flexibility is required, while the closed assembly of the motorized lead screw actuator is ideal to further simplify the design process and remove requirements for external guidance.Customization Options

Thomson routinely collaborates with original equipment manufacturers globally to solve problems, boost efficiency and enhance the value passed on to their customers. Our technology and application experience can be harnessed to help you go beyond standard products to fit the exact needs on your next product.Where Can You Get Started?

Thomson provides extensive online resources to help you no matter where you may be in the purchase decision process:VIDEO: Stepper Motor Linear Actuator Assembly Configurations

Precision lead screws can be combined with a stepper motor in a number of ways. At Thomson, we offer three configurations of stepper motor linear actuators to meet the various needs of our customers' applications. Learn more about them and discover which of them can benefit your linear motion designs.

VIDEO: What is a Stepper Motor and How is it Useful for Linear Motion?

Combined with a precision lead screw, the stepper motor is utilized in one of Thomson’s main product families – stepper motor linear actuators. This video takes a closer look at this motor, its main components, how they work, and why they are useful in linear motion applications in comparison to other types of motors.

VIDEO: Stepper Motor Linear Actuator with Taper-Lock

Learn how to correctly service the Thomson stepper motor linear actuator in the field. The precision-engineered units combine a hybrid stepper motor and lead screw in one, compact envelope to provide clear advantages with a solution that is smaller, stronger, and more efficient than alternate technologies.

Technical Articles

-

Leveraging Stepper Motor Linear Actuator Configurability

When designers and integrators need simple, flexible and compact linear actuation, they often turn to stepper motor linear actuators (SMLAs). The high configurability of SMLAs is among their greatest virtues, but sorting through myriad configuration options to tailor the optimal solution for a particular application can be a challenge for even the most seasoned motion engineer. Understanding the unique capabilities and limitations of each type of SMLA will make it easier to take maximum advantage of their wide range of flexibility.

Learn More -

Implementing Anti-Rotational Guidance for Stepper Motor Linear Actuators

Integrating lead screws with stepper motors is a simple and cost-effective method of getting precise linear motion. But achieving that precision requires anti-rotational guidance, which must either be added externally by the user or designed in by the manufacturer. Determining which option makes sense for you requires an analysis of your need for a guidance system and weighing the advantages and disadvantages of each approach.

Learn More -

Reduce Your Linear Motion Assemblies to a Single Component with Motorized Lead Screw Actuators

When it comes to specifying linear motion within a machine, system designers have many options from which to choose. Making the right choice can impact the ease of installation, footprint and cost of operation. A common driving mechanism for achieving linear motion is a stepper motor and externally supported lead screw-based assembly. A simpler, easier-to-install approach, however, is to select a drive mechanism with built-in guidance and support, thus removing the need for external components that would normally perform these functions and the complexity that comes with them.

Learn More

Stepper Motor Linear Actuator Specifications (Inch Units):

| S = Rotating Screw (MLS), N = Rotating Nut (MLN), A = Actuator (MLA) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Linear Travel / Full Step (μ in.) |

Lead (mm) |

Lead Designator (mm) |

Motor | |||||||||

| MLxX8 | MLx11 | MLx14, MLx17 | MLx23 | |||||||||

| Diameter Designator [hundredths of in. diameter] | ||||||||||||

| 18 | 18 | 25 | 25 | 31 | 37 | 31 | 37 | 43 | 50 | |||

| 0.063² | 0.013 | 0013 | S,A¹³ | S,N,A¹³ | S¹³ | S¹³ | S,N¹³ | S,N,A¹³ | S¹³ | |||

| 0.125² | 0.025 | 0025 | S,A¹³ | S,N,A¹³ | S¹ | S,N,A¹ | S¹³ | |||||

| 0.157 | 0.031 | 0031 | S,A | S,N,A | S¹ | S,N,A¹ | ||||||

| 0.165 | 0.033 | 0033 | S¹ | |||||||||

| 0.179 | 0.036 | 0036 | S,A¹³ | S,N,A¹³ | ||||||||

| 0.200 | 0.040 | 0040 | S¹ | S,N,A¹ | ||||||||

| 0.209 | 0.042 | 0042 | S,A¹³ | S,N,A¹³ | S¹³ | S¹³ | S,N¹³ | S,N,A¹³ | ||||

| 0.250 | 0.050 | 0050 | S,A | S,N | S,A¹ | S,N,A¹ | S¹ | S,N,A¹ | S¹³ | S¹³ | ||

| 0.313 | 0.063 | 0063 | S,A¹ | S,N,A¹ | S | S,N,A | S¹ | |||||

| 0.357 | 0.071 | 0071 | S,A¹ | S,N,A¹ | ||||||||

| 0.394 | 0.079 | 0079 | S,A¹ | S,N,A¹ | S¹ | S,N,A¹ | ||||||

| 0.417 | 0.083 | 0083 | S | S¹ | S,N | S,N,A¹ | ||||||

| 0.490 | 0.098 | 0098 | S¹ | |||||||||

| 0.500 | 0.100 | 0100 | S,A | S,N | S | S,N,A | S¹ | |||||

| 0.591 | 0.118 | 0118 | S,A¹ | S,N,A¹ | ||||||||

| 0.625 | 0.125 | 0125 | S,A¹ | S,N¹ | S,A | S,N,A | S¹ | S,N,A¹ | S¹ | |||

| 0.787 | 0.157 | 0157 | S,A¹ | S,N,A¹ | ||||||||

| 0.833 | 0.167 | 0.167 | S | S | S,N | S,N,A | ||||||

| 0.960 | 0.192 | 0.192 | S,A¹ | S,N,A¹ | ||||||||

| 1.000 | 0.200 | 0200 | S,A | S,N | S,A¹ | S,N,A¹ | S¹ | S,N,A¹ | S¹ | |||

| 1.180 | 0.236 | 0236 | S¹ | |||||||||

| 1.250 | 0.250 | 0250 | S,A¹ | S,N,A¹ | S | S | S,N | S,N,A | S¹ | S¹ | ||

| 1.500 | 0.300 | 0.300 | S¹ | S,N,A¹ | ||||||||

| 1.665 | 0.333 | 0.333 | S,A¹³ | S,N¹³ | ||||||||

| 1.875 | 0.375 | 0.375 | S,A¹³ | S,N¹³ | S¹ | S,N,A¹ | ||||||

| 2.000 | 0.400 | 0.400 | S,A | S,N | ||||||||

| 2.500 | 0.500 | 0500 | S,A¹³ | S,N¹³ | S,A | S,N,A | S | S | S,N | S,N,A | S¹ | S¹ |

| 3.750 | 0.750 | 0750 | S,A¹³ | S,N,A¹³ | S¹³ | S,N,A¹³ | ||||||

| 4.000 | 0.800 | 0.800 | S¹³ | |||||||||

| 5.000 | 1.000 | 1000 | S³ | S³ | S,N³ | S,N,A³ | S¹³ | |||||

| 6.000 | 1.200 | 1.200 | S¹³ | S,N,A¹³ | ||||||||

| 7.500 | 1.500 | 1.500 | S¹³ | |||||||||

1. Some leads may not be available in high-performance nut material, rotating nut (MLN) configurations or some anti-backlash nuts. Contact Thomson for more detail.

2. Fine-pitched lead screws may have substantially lower load capacities compared to traditional lead screws.

3. Lead screw not available in precision grade accuracy (P)

Stepper Motor Linear Actuator Specifications (Metric Units):

| S = Rotating Screw (MLS), N = Rotating Nut (MLN), A = Actuator (MLA) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Linear Travel / Full Step (mm) |

Lead (mm) |

Lead Designator² (mm) |

Motor | ||||||||

| MLxX8 | MLx11 | MLx14, MLx17 | MLx23 | ||||||||

| Diameter Designator | |||||||||||

| M04 | M04 | M06 | M06 | M08 | M10 | M08 | M10 | M12 | |||

| 3 | 0.6 | 006 (0024) | S,A¹ | S,N,A¹ | |||||||

| 5 | 1.0 | 010 (0039) | S | S,N | S,A | S,N,A | |||||

| 6 | 1.2 | 012 (0047) | S,A¹ | S,N,A¹ | |||||||

| 10 | 2.0 | 020 (0079) | S | S | S,N | S,N,A | S¹ | ||||

| 15 | 3.0 | 030 (0118) | S | S,N,A | S¹ | ||||||

| 20 | 4.0 | 040 (0157) | S | S,N | S | S,N | S¹ | ||||

| 25 | 5.0 | 050 (0197) | S | S,N,A | |||||||

| 30 | 6.0 | 060 (0236) | S,A | S,N,A | S¹ | S,N,A¹ | S¹ | ||||

| 40 | 8.0 | 080 (0315) | S³ | S,N³ | S | S,N | |||||

| 50 | 10.0 | 100 (0394) | S | S,N,A | S¹ | ||||||

| 60 | 12.0 | 120 (0472) | S,A | S,N,A | S | S¹ | S,N | S,N,A¹ | |||

| 75 | 15.0 | 150 (0591) | S¹ | ||||||||

| 80 | 16.0 | 160 (0630) | S¹ | ||||||||

| 90 | 18.0 | 180 (0709) | S,A¹³ | S,N,A¹³ | |||||||

| 100 | 20.0 | 200 (0787) | S³ | S | S,N³ | S,N,A | |||||

| 125 | 25.0 | 250 (0984) | S¹³ | ||||||||

| 175 | 35.0 | 350 (1378) | S¹³ | S,N,A¹³ | |||||||

| 225 | 45.0 | 450 (1772) | S¹³ | ||||||||

1. Some leads may not be available in high-performance nut material, rotating nut (MLN) configurations or some anti-backlash nuts. Contact Thomson for more detail.

2. Lead designations for MLA are shown in parenthesis.

3. Lead screw not available in precision grade accuracy (P)

Stepper Motor Linear Actuator Highlights

- Increased Torque Density

- Improved Efficiency

- Rotating Screw, Rotating Nut or Actuator

- Custom Sizes/Leads Available

- Taper Lock Advantage

- Reduced Noise

- Inch or Metric Versions

Stepper Motor Linear Actuator Applications

- Medical Devices

- X-Y Stages

- 3D Printing

- HVAC Control Valves

- Pipetting Devices

- CNC Machines

- Fluid/Syringe Pumps

Brochures

| Stepper Motor Specification Change Notice | 362 KB | |

| Stepper Motor Linear Actuators | 11778 KB | |

| Stepper Motor Linear Actuators | 9252 KB | |

| Stepper Motor Linear Actuators | 4289 KB | |

| Stepper Motor Linear Actuators | 3629 KB | |

| Stepper Motor Linear Actuators | 4437 KB | |

| Miniature Components and Systems | 6871 KB | |

| Miniature Components and Systems | 6862 KB |

Manuals

Choose Your CAD Model:

MLA

MLS

MLN

To download the models below, you will need to sign in.

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].