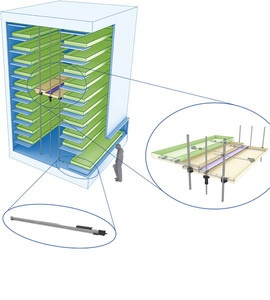

Moving materials in and out of storage can often create major logistical challenges. In fact, simply finding the right item at the right time can be the biggest hurdle. An automatic storage system, such as a vertical lift module (VLM) shown here, can be a solution. This type of automated storage system features a computer-controlled mechanism that stores and keeps track of items. The challenge for such a system is to be able to handle items quickly while maximizing the storage area. Thomson has several standard products that are well-suited to this type of application, as well as the ability to design a customized solution if needed.

Shelf Picking System:

The vertical movement of the shelf picker is carried out by two lead screws, guided by four profile rail linear guides. The horizontal movement also uses two lead screws and four profile rails, configured so that the shelf picker can pick from the shelf stacks at both the front and the back.

Shelf Positioner:

Here, two linear motion systems work parallel to each other moving shelves in and out of the VLM. Their small size, minimal maintenance requirements and high resistance to dirt and dust makes them a good choice for this exposed location.