Few industries place as much demand on a handling system as aircraft construction. The handling of very large and heavy objects, the need for extreme accuracy and unyielding quality standards make for a difficult challenge. At Thomson, we have both the unique experience and the products to meet the precise needs of the most demanding material handling applications.

Aircraft Wing Handling:

In this instance, a wing is transported along a line. At a machining assembly station, the oversized and immensely heavy wing is brought in and tilted 90 degrees. The sheer size and weight of the wing makes the job particularly challenging.

Round Way Roller Bearings:

Round Way Roller Bearings have the strength and accuracy to be able to transport an entire wing along the line. Unlike most linear bearings, Round Way are very forgiving. For instance, the bearings can pass from one shaft to another without losing accuracy, even if they are not perfectly aligned. This makes it possible to build large systems quickly and easily.

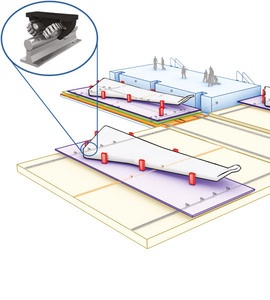

Tilt Station Transport Platform:

To get the wing in and out of the tilt station, the wing fixture is brought on to a transport platform. The platform rides on a set of Round Way bearings and is moved in and out of the tilt station by a ball screw assembly that includes a Micron planetary gearhead. This combination allows the wing to be correctly positioned with accuracy high enough to allow for machining.

Tilt Station with Screw Jacks:

Once the tilt station transport platform is correctly positioned in the tilt station, three Thomson worm gear screw jacks tilt the wing and the platform 90 degrees. In this position, machining and assembly work can be carried out on the wing. The screw jacks are easy to synchronize, have high accuracy and efficiency, and have proven to be quite rugged and reliable.