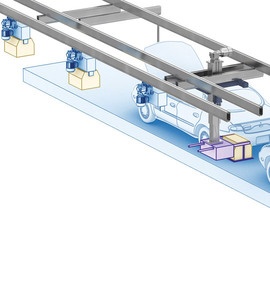

An assembly line requires a steady flow of materials to specific assembly points along the line. An overhead conveyor system is a convenient solution, in that it does not occupy any floor space, yet can still transport materials a great distance. Such a system can also be used when its necessary to position assembly tools and equipment. The main challenge is that the quick pace normally found on an assembly line requires such systems to be lightweight, to make it possible for operators to move the equipment quickly and accurately and lower the risk of fatigue and injuries. Thomson has pioneered a family of products and services to meet the challenge.

The Movorail System:

The Movorail system has been a mainstay of the automotive industry for more than twenty years. Movorail is a lightweight, maintenance-free, modular crane rail system that comes in four sizes for loads up to 600 kg per rail. Due to its modularity and broad range of accessories, it is possible to build just about any imaginable type of conveyor or crane rail system. All you need to mount it is a few common tools, making the system easy to reconfigure or move to another location if neccessary.

Movorail with Telescopic Crane Rail:

In this Movorail system, a telescopic crane rail is mounted so that it can move a power tool over the hood of a car. When the work is done it can be pushed back to a neutral position allowing the car to pass.

Movorail Conveyor System:

Almost any type of conveyor system can be easily built with Movorail rails. Motorized trolleys can carry up to 600 kg. Plus, the system includes curves, switches and turntables, making it possible to bring materials from multiple locations to an assembly point.

Lifting Devices:

Thomson has several units designed for lifting operations. In this case the telescopic lifting unit Movoz Z3 is suspended in a Movorail system. The lifting movement is motorized while the X and Y movements can be manual or motorized. In this application, the operator picks an engine from the conveyor system with a custom made tool attached to the bottom of the lifting unit, rotates it 180 degrees and then positions it in the engine compartment of the chassis, all while the car on the conveyor keeps moving forward.