Better, Faster, Smarter

Thomson products and know-how help you design equipment that is better, faster, smarter.

In a modern production environment, moving material quickly, accurately and efficiently is a big challenge. Using the optimal motion control products can enable you to help your customers save time and money, giving you a competitive edge.

Thomson's Competitive Components:

1) Superior Products - We have the broadest selection and readily provide standard, modified standard, and full custom solutions. Our designs, manufactuers and optimizes:

- Linear rod and rodless actuators

- Linear guides and bearings (round and square rail)

- Ball and lead screws

- Linear slides and systems

- True planetary gearheads

- Wrap spring and friction clutches, spring set brakes and resolvers

2) Superior technology - Thomson successfully supplies components and solutions for material handling applications to companies in automotive, aerospace, food, medical and many other industries. All are built with the same quality and performance that has made Thomson a world leader in motion. Enjoy peace of mind throughout the production life of your material handling equipment with Thomson components.

3) Unbiased Design Solutions - Our unmatched breadth of line encourages designs that don’t compromise - assured by our commitment to fully agnostic solutions. We have tremendous ability to test your application load and movement profiles to develop optimal solutions with over 60 years of experience in optimal, standard, modified-standard, and full custom designs.

- Zero-setup products for speed-to-market and cost effectiveness

- Electric actuator conversion from hydraulic or pneumatic

- Online sizing and selection tools

Integrate Our Expertise Into Your Design Process:

When experienced Thomson engineers contribute early in your design process, you optimize machine performance, life and cost. Leverage our capacity for analysis, modifications and white sheet solutions. Take advantage of smart standardization that gives you more freedom and improved speed to market. And then rest easy knowing that the results will be predictably excellent. Here are some of the keys:

- We Develop

Standard platforms that make any design easily customizable. - We Produce

Zero set-up products to get our clients to market faster and more cost-effectively. - We Test

Extensively on your equipment to enable evaluation of our products in your application.

Couple these process advancements with our highly proven, highly engineered components and pre-assembled systems, and you’ve optimized your food-processing machine project.

We Participate in a Wide Range of Applications:

- AGV trucks

- Automatic storage equipment

- Conveyor systems

- Elevators

- Ergonomic improvements

- Extraction equipment

- Feeding equipment

- Fork lifts

- Lifting aids

- Manipulators

- Overhead crane systems

- Patient lifts

- Palletizers

- Pick and place

- Robots

- Safety improvements

- Storage equipment

- Transportation equipment

- Airport baggage handling equipment

Applications

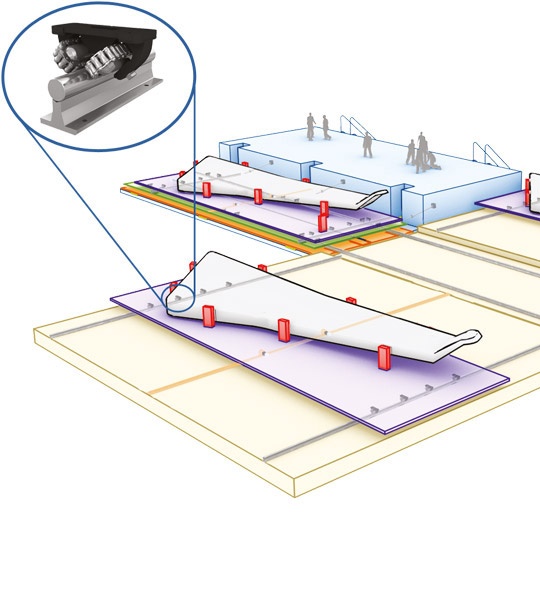

Aircraft Wing Handling

Few industries place as much demand on a handling system as aircraft construction. The handling of very large and heavy objects, the need for extreme accuracy and unyielding qualit...

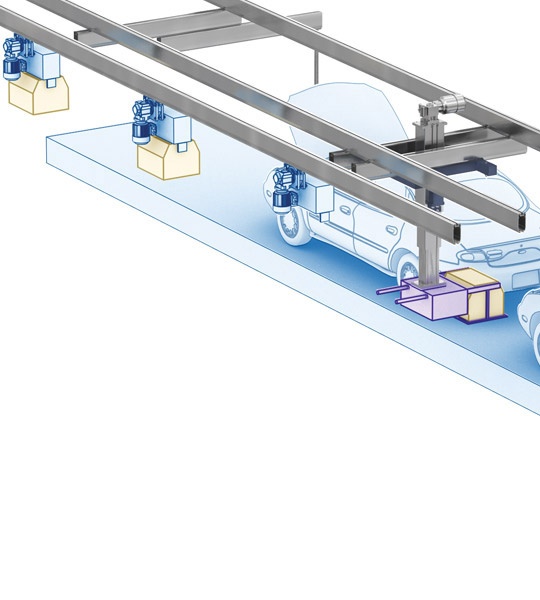

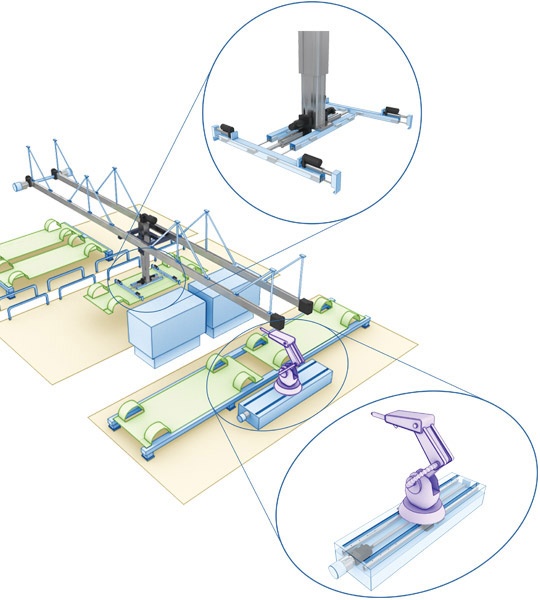

Assembly Line Engine Handling

An assembly line requires a steady flow of materials to specific assembly points along the line. An overhead conveyor system is a convenient solution, in that it does not occupy an...

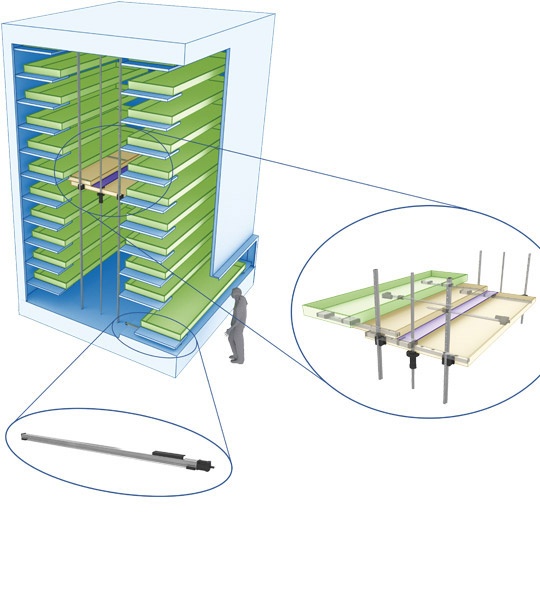

Vertical Lift Module - Automatic Storage

Moving materials in and out of storage can often create major logistical challenges. In fact, simply finding the right item at the right time can be the biggest hurdle. An automati...

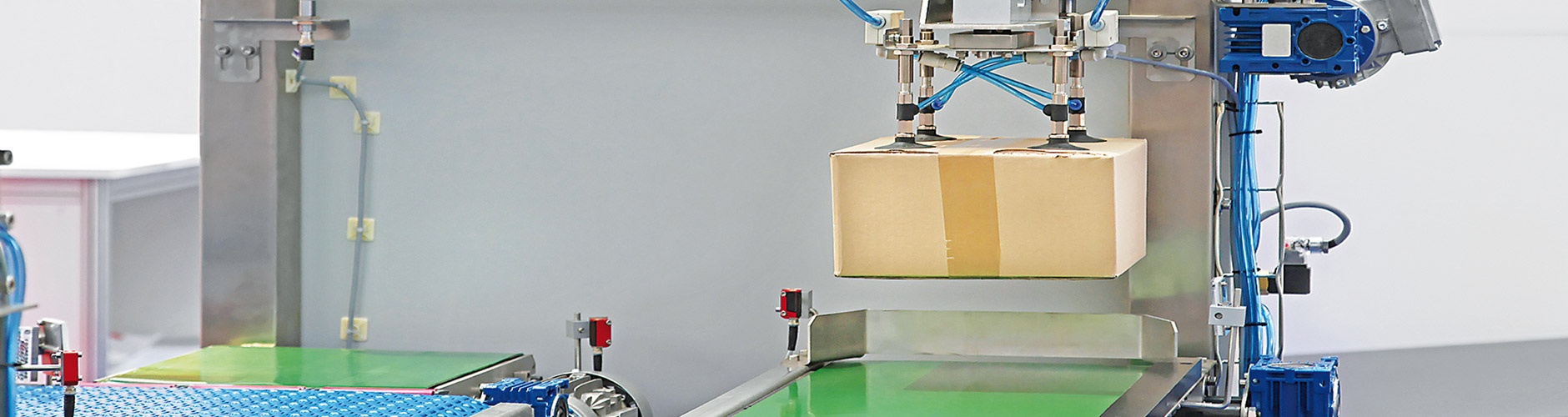

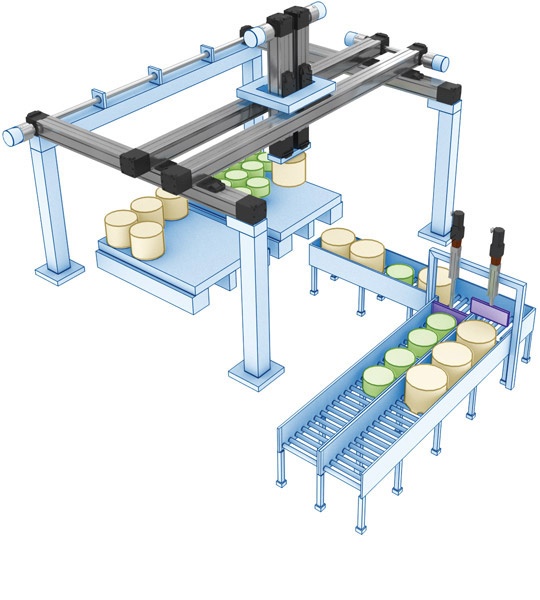

Food Container Palletizing

The food industry places high demands on material handling equipment. Harsh conditions found in places such as dairies, bakeries and breweries means equipment is often exposed to e...

Car Chassis Transportation

Material handling solutions sometimes involve bringing together production cells that can’t be placed adjacent to each other. Moving goods, parts or components between these cells...

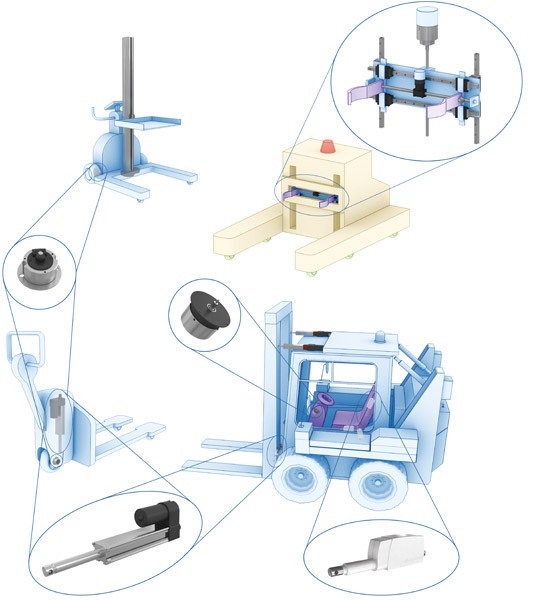

Trucks and Mobile Lifting Aids

Trucks and mobile lifting aids perform a large percentage of material handling in modern workshops. The applications shown here are just a few examples of what products and solutio...