Não importa como você define “personalizado” ou “modificado” em relação aos componentes de movimento linear, a Thomson tem a solução certa para você.

CONTE COM A THOMSON PARA:

- Dedicar-se à colaboração

- Aproveitar o sucesso de nossas soluções anteriores

- Perseverar na exploração de soluções potenciais

- Acessar conhecimento especializado e modelos CAD

- Comunicar-se de forma consistente e com alta frequência

- Dar continuidade a um plano acordado

- Entregar protótipos com rapidez

- Manter um olhar atento sobre o orçamento

Tudo pronto para começar seu projeto ou ainda tem dúvidas?

Ligue para 540-633-3549 ou clique em qualquer uma das opções abaixo para falar com um engenheiro:

定制化解决方案示例

客户类型: 患者搬运OEM

产品/应用:病人病床轮锁,可将治疗台安全地抬离地面

设计挑战和考虑因素: 客户的原始设计是一种两件式解决方案,在梯形丝杠和超大轴颈接缝处存在受力问题

Thomson 解决方案: 采用超大轴颈的0.625英寸直径 x 0.100英寸梯形丝杠作为一件式结构。该组件具有更坚固的结构,不仅可以承受重载,还可以延长生命周期。

结果:客户批准并订购了这一独特设计,解决了其负载问题

客户类型: 工业OEM

产品/应用:高层建筑窗锁

设计挑战和考虑因素: 为了增加窗户功能的平滑度并实现窗锁组件的现代化,客户寻求将摩擦元件改为滚动元件

Thomson 解决方案: 一体式铝制机加工支撑导轨,具有超薄 整体尺寸紧凑的特点,适合窗锁位置的狭小空间

结果:60 Case® 导轨不仅解决了锁具设计的空间狭小这一难题,而且使窗户运动更顺畅

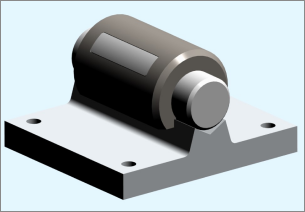

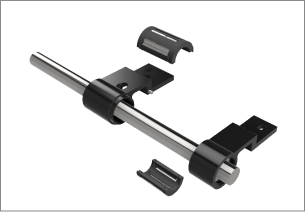

客户类型: 工业OEM

产品/应用:列车门移动

设计挑战和考虑因素: 为了在空间受限的门内正确维护轴承,客户必须完全拆卸门和直线单元,才能每季度更换一次轴承

Thomson 解决方案: 采用两件式铝制支架和分体式轴承设计,安装更方便,无需拆卸整个直线单元

结果:客户无需拆卸单元即可更快地安装轴承,从而将维护时间缩短了50%