Selecting Actuation Components for Maximum End-user Value and OEM ROI

Chad Carlberg, Product Line Manager for Linear Actuators, Thomson Industries and Chris Diak, Motion Industries

When selecting between fluid driven and electromechanical linear actuators, close consideration of long-term benefits to the intended end user can help OEM system designers maximize both product value and ROI.

Fluid-driven actuators translate electric energy motion through a column of air, gas, oil or other media. While the motion they provide is simpler, the infrastructure required to support them is not. Hydraulic actuators require an external system of pumps and valves; while pneumatic actuators require complex air delivery systems. For both, stroke length is defined by a mechanical hard stop.

Electromechanical systems, on the other hand, can handle more complex operations with a much simpler design. An electric motor – through a belt gear, a worm gear, a planetary gear or via a coupling directly – rotates a ball screw which translates the torque into axial force through the extension tube. All key motion components are – or can be – self-contained. Motion is controlled by a programmable electronic signal.

Here are eight selection criteria that system designers should consider when choosing between fluid-driven and electromechanical actuators.

1. Control of the motion profile.

As business volatility and complexity increases, users of actuator-driven machinery and equipment are demanding greater control over position, velocity or force throughout the range of motion. Fluid-driven actuators cannot provide this easily. It is difficult for them to achieve slow, controlled speeds that may be needed in many applications.

To some extent, fluid-based actuators can gain control using external systems such as proportional regulators, valves, and encoders, but this adds cost and further complexity. Because electromechanical motion is controlled electronically, the device can be programmed to stop at any point along the stroke. Force and motion profiles can be changed in software without having to shut down and reconfigure the machine.

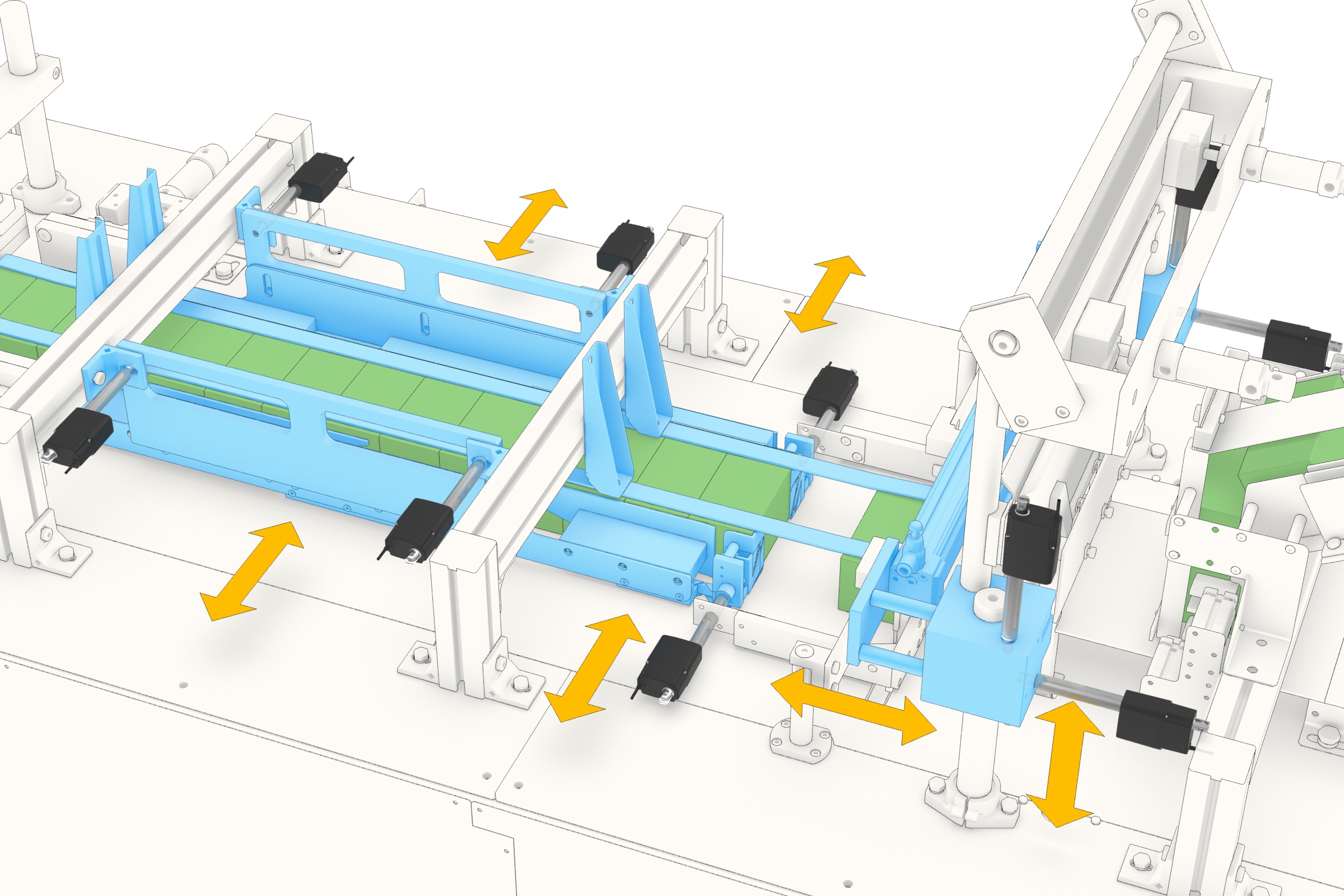

The increased controllability of electromechanical actuators can often eliminate the need for changeover when switching from one product to another. In applications, such as packaging lines, where numerous package sizes may run in a single shift, this can result in significant savings.

Packaging lines benefit from the increased controllability of electromechanical actuators as they often eliminate the need for changeover when switching from one product to another. (Images courtesy of Thomson Industries, Inc.)

Electromechanical actuators can also be networked with each other, enabling functionality such as synchronization, making it easier for end-users to work with unbalanced loads.

2. Impact on cleanliness and safety

In addition to limiting control over the motion profile, fluids make for a grimier, potentially dangerous work environment. Hydraulic fluids, for example, must be transported and stored. Ever-present leakages must be cleaned and can contribute to slip and fall accidents on the plant floor. Various filtration methods must be used to reduce contaminants, and when the fluid has fully degraded, it must be changed and disposed of carefully. Pneumatic actuators present similar issues due to the presence of oil and other impurities in the compressed air supplies. The exhausted air must be filtered to remove impurities before it is released into the environment.

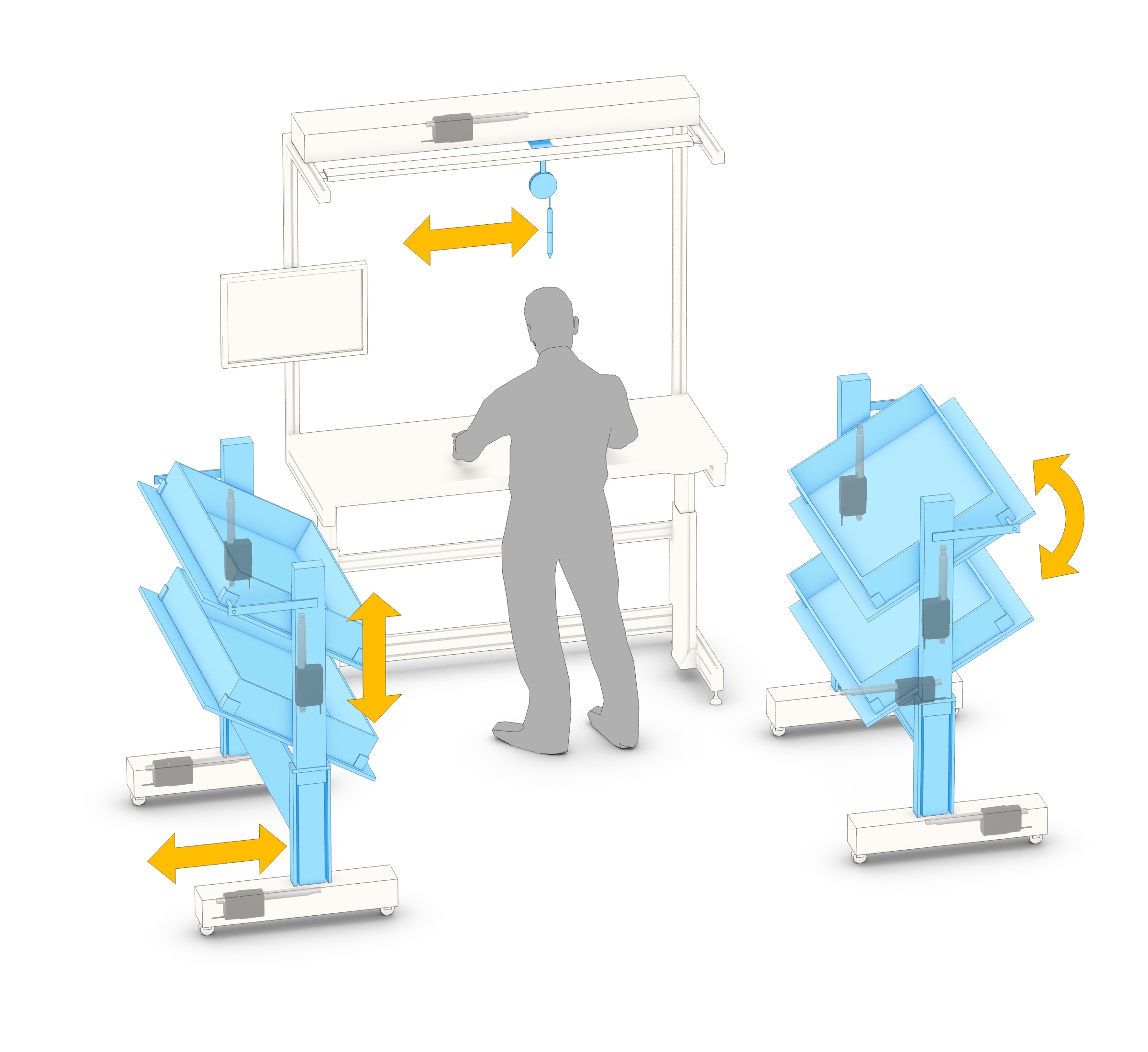

Electromechanical actuators have no such issues. All motion is in precision-fit metal parts, which require only routine lubrication – or in some cases no lubrication at all. Given that, electromechanical actuators are especially appropriate for use in sanitary applications that require ultra-clean operation such as in the food, beverage, packaging, medical and electronics manufacturing industries.

Electromechanical actuators are ideal for use in sanitary applications that require ultra-clean, energy efficient operation. (Images courtesy of Thomson Industries, Inc.)

And because all components are contained in sealed modules with high ingress protection, electromechanical actuators are also more suitable for environments with higher contamination risk: chemical plants, paper mills, welding operations and outdoor applications.

3. Durability and maintenance

Just avoiding the grime and contamination of fluids itself reduces pressure on maintenance resources, but the greatest contributor to the maintenance workload is the complexity of fluid-based systems.

Routine, break/fix-style maintenance is essential for fluid-based systems. Oil loses efficiency and must be checked. Gaskets and seals are subject to damage and wear. Infrastructure components must be monitored and replaced as needed. Electromechanical actuators run longer with no maintenance intervention providing consistent performance for the entire lifetime of the actuator.

4. Ambient noise

Noise is a significant issue with both hydraulic and pneumatic actuators. A hydraulic system consists of an electric motor, bearings, rotor and stator assembly, and a fan. The motor drives a pump, which pressurizes hydraulic fluid in the cylinder, via a valve. The fluid itself is transmitted through a system of tubing, hoses and fittings.

To maintain the pressure, this system must be kept idling all the time, which produces additional baseline noise that can often be heard throughout the plant, adding to ambient environmental noise levels. This is such a concern that products offering noise mitigation on hydraulic systems have become an industry in itself.

With pneumatic actuators, noise is mostly the result of air leaks, which are always present. Pressure losses and impurities found in compressed air supplies impact pneumatic actuators causing increased energy usage and noise levels. The design of electromechanical actuators makes their operation very quiet. This technology is continuously advancing to achieve quieter operation to be used in applications not possible for the other media actuators. There is an electromechanical actuator on the market, for example, that operates with a sound level of less than 45 dB — about the same as a typical library.

5. Energy efficiency

Fluid actuators use energy very inefficiently because they go through a two-step energy conversion process. Hydraulic systems have the advantage of being able to hold pressure constant without having to apply additional amounts of energy, but this requires keeping a pump running continuously, even when the actuator is not performing any work. With pneumatic actuators, escaping air through leaks increases energy usage and ambient noise levels.

In contrast, electromechanical technology uses energy only when doing work, and does so with high efficiency. More than 90 percent of the energy applied to an electromechanical ball and roller screw assembly is converted to work. An electromechanical device can also hold a load in place without expending additional energy or complex system assemblies.

6. Space efficiency

The fact that everything in an electromechanical actuator can be self-contained in a compact unit means that the OEM can make smaller machines. This size reduction helps end users add automation to smaller spaces, improving efficiencies of both operation and space utilization. Certain manufacturers have gone one step further in making actuators with a single mount capability, making it easier for OEMs to deliver smaller systems.

Electromechanical actuators take up less space and improve efficiencies of both operation and space utilization. (Images courtesy of Thomson Industries, Inc.)

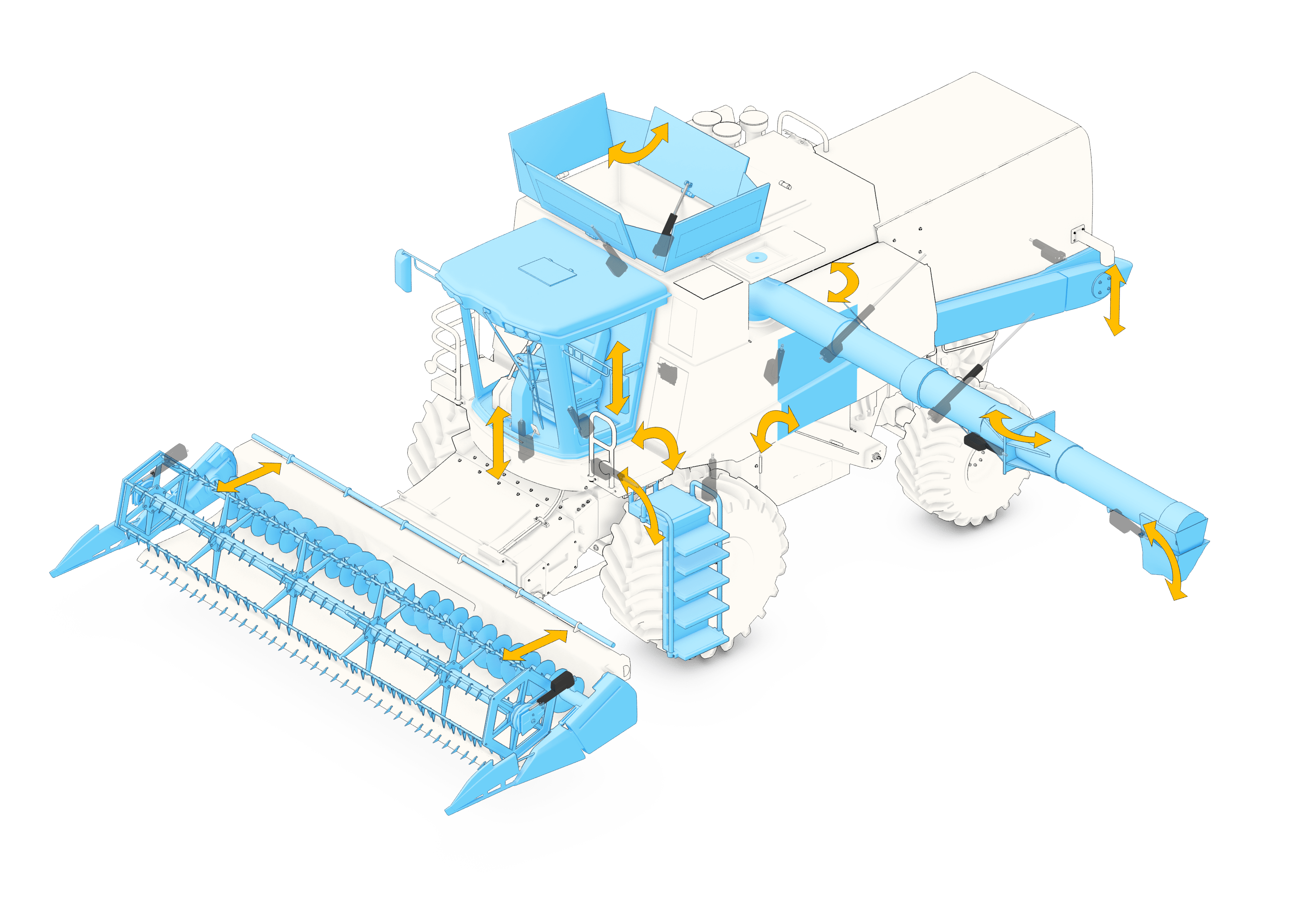

7. Integration with other applications

As industrial systems become smarter and more connected, opportunities to optimize production to new levels of quality, efficiency and cost control are emerging. Many of these involve exchanging operational data across workplaces via the cloud. Fluid actuators are not as equipped to play in those applications as additional hardware is often required to provide what is integrated in electric actuators. This additional technology requirement makes integrating fluid actuators into process optimization or modernization strategies more costly and difficult at times.

Electromechanical actuators connect to networks with only a few wires, making it easier for them to exchange performance information among actuation devices as well as with optimization software.

8. Total cost of operations

While each selection criteria discussed thus far translates into end user value to some degree, an electromechanical actuator’s greatest contribution is most likely its role in reducing total cost of operations. Greater control over the motion profile means there is no need to buy complex add-on components, servo valves or other components to control operations.

Cleaner operation and reduced maintenance contribute to the bottom line in reducing the cost of labor otherwise needed to monitor and repair systems. Using electromechanical actuators eliminates the expense of hydraulic oil associated with traditional hydraulic systems.

Because electromechanical actuators run longer without needed maintenance, manufacturers will save on replacement purchases and inventory management. The ability for electromechanical actuators to convert 90 percent of energy to work allows a plant to save thousands in energy costs. In energy intensive industries, energy cost savings can justify upgrades to electromechanical actuators with system paybacks in as little time as a year.

More efficient space utilization can have a significant financial benefit, especially in areas where real estate values are high or on offshore and remote operations. Going forward, it may be that the greatest financial benefit of using electromechanical actuators is in their readiness for integration into the digital age. Companies are making gains by pulling device data into asset management software, enabling greater predictive management of processes and assets.

A key aspect for system designers is ensuring that the right components are selected and integrated to deliver accuracy, efficiency, precision, noise level and other performance characteristics. Many companies manufacturing electromechanical actuators will offer online self-service sizing and selection tools that enable designers to accurately size and select linear motion systems and other components.

Sidebar:

Selecting Motion Control Components

As industrial technology advances, and electromechanical actuators and other motion control components expand in capabilities for heavy duty applications, system designers are faced with a wide variety of options for their projects.

Application and selection tools make it easier for design engineers to select the right product for their specific application needs, providing an effortless navigation experience to help identify the ideal actuator solution quickly.

To ensure the best fit, they should take into account a handful of end-user considerations when making their selections:

1. How much control will the end user have over motion profiles?

2. How clean is the operating environment? What are the potential hazards?

3. What is the stated lifecycle? How much maintenance is required?

4. How quiet is the system?

5. How energy efficient is it?

6. How much space is required for operation?

7. How easy is it to integrate with other applications?

8. What is the impact on total cost of operating?

Sharing the Benefit

Most of the same features that make electromechanical actuators more valuable to end users than fluid-based systems also make it easier for OEM system designers to deliver that value. Pneumatic or hydraulic technology requires working with complex, space-consuming infrastructures.

Electromechanical actuators are simpler and easier to size. In a few steps, designers can determine the required load and duty cycle and specify stroke and retraction length. Modern configuration tools make this process even easier. Once an actuator is determined, the end user determines a location, mounts and wires it with a few wires, and the actuator is up and running. Designers of fluid-based systems do similar calculations, but must consider the additional system requirements of how to locate and sustain the fluid supply to the actuator.

Because they deliver so many benefits to end users, electromechanical actuators can help OEMs field a more competitive offering. Being they are easier to work with and more versatile, electromechanical actuators can also reduce design and development costs.

Maximizing Value and ROI

In addition to providing system designers with an easier and more versatile motion component than fluid actuators, electromechanical linear actuators provide significant advantages to both end users and OEMs. They are cleaner, easier to integrate, control and maintain, quieter and more energy efficient. Additionally, they take up less space ̶ all of which contribute to a lower total cost of operation and last longer without maintenance. Hydraulic and pneumatic alternatives certainly have their place, but best practice is to consider all alternatives when deciding which actuation technology would be best for the application.