Choose Your Login Account

Thomson currently has two account systems - one for the website and CAD model downloads, and one for e-commerce. We understand that two logins is an inconvenience and are working to consolidate our systems into one login process. Until we’re able to consolidate the two logins, please follow these guidelines:

- Download CAD models

- Save and retrieve projects in LinearMotioneering® and MicronMotioneering® tools

- Access Distributor Extranet and all related resources

- Order directly from Thomson online (North America only)

- Authorized Thomson Distributors can view and order from quotes online (Global)

- View the shopping cart and look up prior direct orders

Customer Service Chat (ONLINE) Customer Service Chat (OFFLINE)

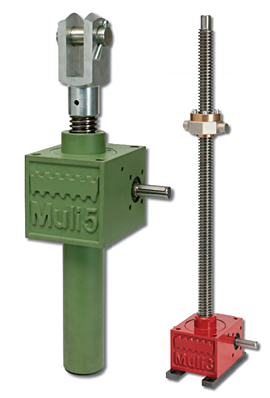

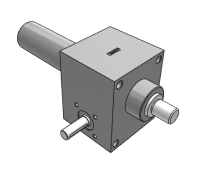

Screw Jacks

ActionJac™ Screw Jacks

USA-made, rugged design and high capacity with sizes from 1/2 to 75 tons.

Thomson Screw Jacks (Metric)

German-made, symmetrical housing allows for universal mounting from either end.

Contact Thomson with any needs you have

Select Product Type

Low Load

Up to 4,000 lbf (Up to 18 kN)

Medium Load

(4,000+ to 40,000 lbf) (18+ to 180 kN)

High Load

(40,000+ to 150,000 lbf) (180+ to 700 kN)

Upright Translating

An Upright Translating jack has a lifting shaft that moves through the gear box.

Inverted Translating

An Inverted Translating jack has a lifting shaft that moves through the gear box.

Upright Rotating

Rotating jack that has a lift shaft that moves a nut as it turns from above.

Inverted Rotating

Rotating jack that has a lift shaft that moves a nut as it turns from underneath.

Double Clevis

Double Clevis Jacks are used when it is necessary to move a load through an arc.

Upright Translating

An Upright Translating jack has a lifting shaft that moves through the gear box.

Inverted Translating

An Inverted Translating jack has a lifting shaft that moves through the gear box.

Upright Rotating

Rotating jack that has a lift shaft that moves a nut as it turns from above.

Inverted Rotating

Rotating jack that has a lift shaft that moves a nut as it turns from underneath.

Double Clevis

Double Clevis Jacks are used when it is necessary to move a load through an arc.

Upright Translating

An Upright Translating jack has a lifting shaft that moves through the gear box.

Inverted Translating

An Inverted Translating jack has a lifting shaft that moves through the gear box.

Upright Rotating

Rotating jack that has a lift shaft that moves a nut as it turns from above.

Inverted Rotating

Rotating jack that has a lift shaft that moves a nut as it turns from underneath.

Threaded End

Ideal for customer supplied mounting solutions.

Top Plate

Provides easier mounting and installation.

Clevis

Allows the load to move through an arc.

Threaded End

Ideal for customer supplied mounting solutions.

Top Plate

Provides easier mounting and installation.

Clevis

Allows the load to move through an arc.

Threaded End

Ideal for customer supplied mounting solutions.

Top Plate

Provides easier mounting and installation.

Clevis

Allows the load to move through an arc.

Threaded End

Ideal for customer supplied mounting solutions.

Top Plate

Provides easier mounting and installation.

Clevis

Allows the load to move through an arc.

Threaded End

Ideal for customer supplied mounting solutions.

Top Plate

Provides easier mounting and installation.

Clevis

Allows the load to move through an arc.

Threaded End

Ideal for customer supplied mounting solutions.

Top Plate

Provides easier mounting and installation.

Clevis

Allows the load to move through an arc.

Design and Installation Notes

Upright Translating Ball Screw Jack

Upright Translating Ball Screw Jack Upright Translating Machine Screw Jack

Upright Translating Machine Screw Jack Inverted Translating Ball Screw Jack

Inverted Translating Ball Screw Jack Inverted Translating Machine Screw Jack

Inverted Translating Machine Screw JackTranslating Jacks

A translating jack has a lifting shaft that moves through the gear box. A nut is integrated with the worm gear such that the worm gear and nut rotate together. When the lift shaft is held to prevent rotation, the lift shaft will move linearly through the gear box to move the load.

Rotating Jacks

A rotating jack has a lift shaft that moves a nut as it turns. The lift shaft is fixed to the worm gear. This causes the load, which is attached to the travel nut, to move along the lift shaft.

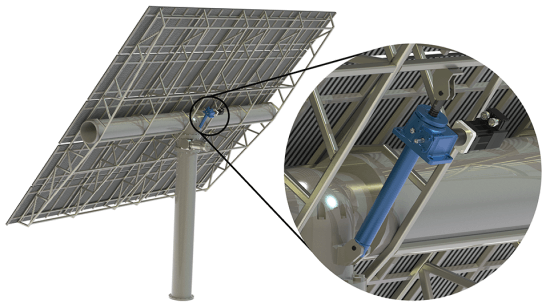

Double Clevis Jacks

Double Clevis Jacks are used when it is necessary to move a load through an arc, such as tracking antennas, hinged doors or air dampers. One clevis is mounted on the end of the lift shaft and the other clevis is welded to a heavy duty stem cover, which is welded to the housing.

Note: Mounting hardware for double clevis jacks should be specified as heat treated alloy steel clevis pins with at least 100,000 psi ultimate tensile strength.

Double clevis jacks used horizontally will have reduced column strength and life. For most horizontal applications, Nook/Thomson recommends the use of an Electric Cylinder (contact Nook/Thomson Engineering for more information).

Jack Configuration

Not finding the screw jack you're looking for? Contact us for a custom solution.

Family

Size

Type

Ratio

Screw Type

Stroke

Screw End

End Fitting

Bellows

Nut

Stop Collar

Special Features

Screw Dimensions

Compare

3D Model

Family

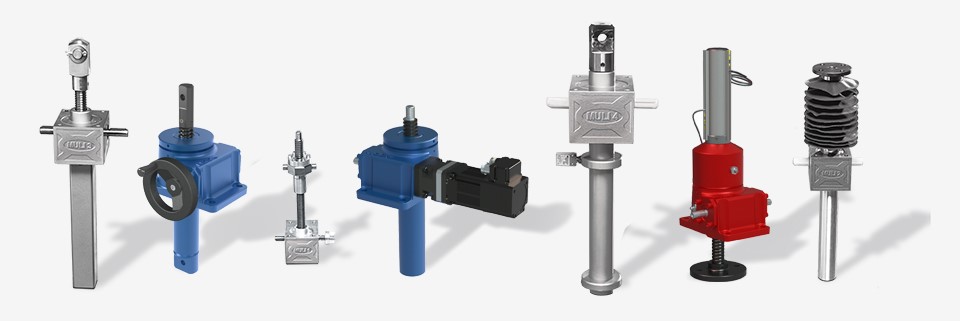

- MULI - Lifting capacities up to 100 kN

- JUMBO - lifting capacities from 150 kN to 500 kN

Size

Type

Rotating Screw - R

The rotary motion of precision worm gearing (worm shaft and internally threaded worm wheel) is converted into axial linear motion of the screw, which travels through the gear box housing. The load is attached to the end of the screw.

Rotating Nut, with or without anti-rotation (axial translating Screw) - N or V

Driven by a precision worm gearing (worm shaft and worm wheel), the rotary motion of the screw is translated into linear motion of the travelling nut on the screw.

Ratio

High Speed - One full turn of the worm shaft leads to a stroke of one millimeter.

Low Speed - One full turn of the worm shaft leads to a stroke of 0.25 mm.

Screw Type

- Ball Screw (KGS) - For longer duty cycles, higher efficiency, high positioning accuracy

- Trapezoidal Screw (TGS) - For tough conditions, good price/performance ratio.

Stroke

The stroke length of the screw jack.

Screw End

Machining that is done to the end of the screw

- Standard Screw End (only for rotating nut) (G) – the end of the screw is machined to fit a standard end fitting.

- Cylindrical end (only for rotating screw) (Z) – the end of the screw is machined to a cylindrical shape

- No End machining (0) – End of the screw is cut to length. No machining is added.

- Special to customer specifications (S) – End of screw is machined to a customer provided specification

End Fitting

- No end Fitting (00) – Standard for rotating screw versions.

- Top Plate (BP)

- Fork End (GA)

- Clevis End (GK)

Bellows

Bellow cover for protection against external influences. Suitable for horizontal or vertical installation.

Nut

- Without Nut (0) – Always fro version rotating nut (N or V)

- Trapezoidal nut (1) – for rotating screw (R) with trapezoidal screw (TGS)

- Flanged ball nut (2) – for rotating screw (R) with ball screw (KGS). Flange of nut towards end of screw standard.

- Cylindrical ball nut (3) – for rotating screw (R) with ball screw (KGS)

Stop Collar

- With Stop collar (A) – Collar to stop the screw from being translated out of the nut. Fitted as standard on ball screw versions N and V. Optionally available for screw jacks with trapezoidal screws. The stop collar cannot be used as a fixed stop.

- Without stop collar (0) – always on rotating screw (R). Optional on rotating nut versions (N and V).

Special Features

- Without (0) – No special features

- Standard (Z) – With some standard accessories added. These are not captured in the part number

- Custom (S) – Special features as described by the customer

Screw Dimensions

The diameter and lead of the screw used. On most units there is only one choice per size and type. On Muli 4 there are 2 different ball screw choices.

- KGS 4005 (1)

- KGS 4010 (2)

All others leave this position in the part number blank.

Customer Service

This part number is not available for sale online but may still be available for sale. Click here to contact Thomson Customer Support.

Customer ServiceStandard Screw Jacks

Ball Screw Jacks

Bevel Gear Ball Screw Jacks

Bevel Gear Machine Screw Jacks

Machine Screw Jacks

Screw Jacks (Metric)

Stainless Steel Machine Screw Jacks

Whether you are lifting, lowering, tipping or moving a load, screw jacks are ideal for various applications requiring a powerful, reliable and easily adaptable solution.

Customization Options

When standard Nook or Thomson screw jacks don’t meet your exact specification requirements, our engineering experts can help customize a solution for your application. Our custom options, which include assembly, nuts, screws, special coatings, thread forms and more, can meet your needs and improve your machine’s performance.

Where Can You Get Started?

Nook and Thomson provide extensive online resources to help you no matter where you may be in the purchase decision process. An example are our screw jack engineering calculators, which allow you to compute specifications key to selecting the ideal screw jack.

Screw Jacks: A Rugged, Flexible Solution for Heavy Duty Linear Motion

Delivering high reliability and life expectancy under varying operating conditions, Thomson and Nook screw jacks are optimal for applications that require high speed, vibration, shock loading, precise positioning requirements and high torsional loads. In this video, learn what goes into making our high-quality screw jacks and how they can be your next linear motion solution.

How to Choose the Right Screw Jack for Your High-Load Applications

With the capability of handling loads up to 100 tons, screw jacks have made a name for themselves when it comes to designing for high-load, linear motion applications. However, determining whether a machine screw jack or ball screw jack is the right fit can be difficult. Each delivers key benefits depending on the application parameters.

This webinar will examine key design considerations as they apply to both screw jack types to help you better and more quickly determine which is more ideal for your application.

• The key features and benefits of machine and ball screw jacks.

• The major differences between these two types of screw jacks.

• The application parameters designers need to consider when choosing between machine and ball screw jacks.

• How to choose the right screw jack for your linear motion designs.

Presenter: Mitch Katona, Product Line Specialist, Thomson Industries, Inc.

Screw Jacks – The Linear Motion Component You Never Knew You Needed

In this webinar recording, learn how to add a new design option to your precision linear motion toolbox. Screw jacks offer your applications a host of benefits, including power, reliability, precision and flexibility.

TECHNICAL ARTICLES/BLOGS:

-

Screw Jacks and Environmental Applications

Nook screw jacks offer the ability to lift, position, hold and support loads in a variety of industrial applications. These jacks will provide excellent performance and reliability in the average indoor industrial facility with a dry environment and an operating temperature of 32oF (0oC) – 180oF (82oC). However, not all applications are in these ideal conditions. Nook offers many options to meet non-ideal conditions.

Learn More -

8 Design Considerations for Screw Jack Systems

Regardless of the type of worm gear jack you are considering (machine screw or ball screw), there are eight factors that are critical for developing the optimal linear motion system. In this post, we will examine these design constraints and how they can impact proper sizing, placement, and configuration of your screw jack system.

Learn More -

3 Quick Screw Jack Applications – Food Industry

There have been some interesting linear motion technical innovations designed to serve the food segment in recent years. But, many of the emerging food applications are still perfect for the venerable screw jack. It's simple yet effective design is timeless, and it is a true work horse for food applications. In the food sector, screw jack systems are typically deployed in three common and versatile arrangements. This post talks about a few of these in more detail.

Learn More

Brochures

| ActionJac Screw Jacks | 457 KB | |

| ActionJac Screw Jacks | 465 KB |

Catalogs

| ActionJac Screw Jacks | 18564 KB | |

| Worm Gear Screw Jacks Muli®, Jumbo® | 5173 KB | |

| Worm Gear Screw Jacks Muli®, Jumbo® | 5230 KB | |

| Worm Gear Screw Jacks Muli®, Jumbo® | 5375 KB |

Manuals

Select Your Screw Jacks CAD Solution

ActionJac™ Screw Jacks (Metric and Imperial)

USA-made, rugged design and high capacity with sizes from 1/2 to 100 tons.

Thomson Screw Jacks (Metric)

German-made, symmetrical housing allows for universal mounting from either end.

| ActionJac Screw Jacks - Ball Screw |  |

— | — |

| ActionJac Screw Jacks - Machine Screw |  |

— | — |

| ActionJac Screw Jacks - Mini Machine Screw |  |

— | — |

| ActionJac Screw Jacks - Stainless Steel Machine Screw |  |

— | — |

| + MULI & JUMBO Screw Jacks - Type N | |||

| MULI & JUMBO Screw Jacks - Type N - TGS |  |

— | — |

| MULI & JUMBO Screw Jacks - Type N - KGS |  |

— | — |

| + MULI & JUMBO Screw Jacks - Type R | |||

| MULI & JUMBO Screw Jacks - Type R - TGS |  |

— | — |

| MULI & JUMBO Screw Jacks - Type R - KGS |  |

— | — |

| + MULI & JUMBO Screw Jacks - Type V | |||

| MULI & JUMBO Screw Jacks - Type V - TGS |  |

— | — |

| MULI & JUMBO Screw Jacks - Type V - KGS |  |

— | — |

0301020011- M1-V-H-TGS-0350-G-00-0-0-A-0, MULI1, Rotating Nut with Screw Anti-rotation

Available from authorized NA distributors near you and Thomson.

0301020014- M1-V-H-TGS-0200-G-00-0-0-A-0, MULI1, Rotating Nut with Screw Anti-rotation

Available from authorized NA distributors near you and Thomson.

0301020015- M1-N-H-TGS-0350-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020017- M1-N-H-TGS-0150-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020019- M1-N-H-TGS-0300-G-BP-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020027- M1-N-H-TGS-0250-G-BP-0-0-A-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020030- M1-N-H-TGS-0200-G-BP-0-0-A-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020035- M1-N-H-TGS-0200-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020042- M1-N-H-TGS-0100-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020056- M1-N-H-TGS-0050-G-00-0-0-A-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020059- M1-N-H-TGS-0300-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020073- M1-N-H-TGS-0180-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020079- M1-N-H-TGS-0150-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020088- M1-N-H-TGS-0180-G-GK-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020110- M1-N-H-TGS-0100-G-BP-F-0-A-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020120- M1-N-H-TGS-0240-G-BP-0-0-A-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020133- M1-N-L-TGS-0080-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020150- M1-N-H-TGS-0140-G-BP-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020159- M1-N-L-TGS-0150-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020178- M1-N-H-TGS-0400-G-BP-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020194- M1-N-H-TGS-0500-G-GA-0-0-A-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020195- M1-N-H-TGS-1100-G-GA-0-0-A-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020196- M1-N-H-TGS-0100-G-BP-0-0-A-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020199- M1-N-H-TGS-0250-G-BP-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020205- M1-N-H-TGS-0140-G-GA-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020212- M1-N-L-TGS-0600-G-BP-0-0-A-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020228- M1-N-H-TGS-1000-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020232- M1-N-H-TGS-0190-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020266- M1-N-L-TGS-0100-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020318- M1-N-H-TGS-0300-G-00-F-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020345- M1-N-H-TGS-0600-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020370- M1-N-H-TGS-0125-G-BP-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020374- M1-N-L-TGS-0070-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020375- M1-N-L-TGS-0250-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020425- M1-N-L-TGS-0165-G-00-0-0-A-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020442- M1-N-L-TGS-0020-G-00-0-0-A-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020443- M1-N-H-TGS-0160-G-BP-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020454- M1-N-L-TGS-0070-G-BP-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020495- M1-N-L-TGS-0120-G-00-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

0301020544- M1-N-H-TGS-0215-G-BP-0-0-0-0, MULI1, Rotating Nut

Available from authorized NA distributors near you and Thomson.

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].