Product Details

The 500 Series Roller profile rail rigidity is

achieved by using the equivalent of a back-to-back bearing arrangement,

complemented by special rollers that are crowned to prevent roller edge

loading when misalignment is present. This results in lower elastic

deformation under load compared to a ball carriage or double faced roller bearing arrangement. Roller guides have an increased load

capacity over the ball profile rail as a result of the increased contacting surface

across the length of the roller.

Precision grade for high-accurate, high-load applications

500 Series Roller features:

- Double-back roller track arrangement

- Reinforced Nylon 6.6 end cap

- Standard end seals and longitudinal seals provide contaminant protection

- Accuracy Class: (Assembly Tolerance)

- P - Precision Grade (±20 μm)

- S - Super Precision Grade (±10 μm)

- U - Ultra Precision Grade (±5 μm)

- Preload options: ("C" being the carriage dynamic load)

- 1 – 0.03C

- 2 – 0.08C

- 3 – 0.13C

- Sizes (mm):

- 25

- 35

- 45

- 55

- 65

Advanced grinding and straightening technologies

- Superior rail straightness

- Running smoothness

- Low noise

- Any carriage can be run on any rail of the same accuracy class without compromising system accuracy

- Industry leading load capacities

- Prevents roller edge loading

- Minimum roller friction

- A - Standard

- B - Standard Long

- C - Narrow

- D - Narrow Long

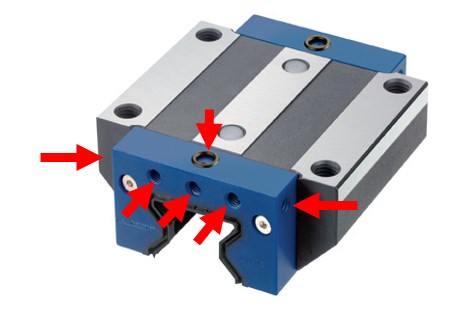

Lubrication Inlet Locations

500 Roller carriage comes with six lubrication inlet locations per side

- The center lubrication plugged with pipe plug

- The side inlets and offset are tapped but sealed, a simple modification will open

- The top requires drilling a small hole and applying an O-ring

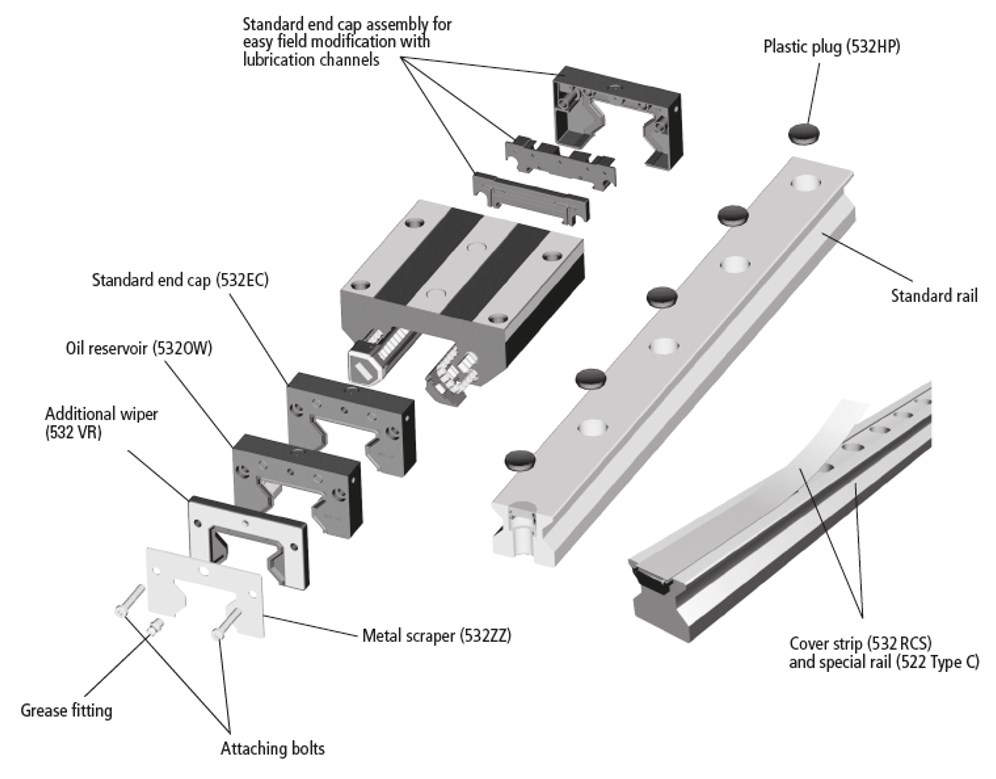

Rail Style

The available rails styles are:

- A – Bolt from top (standard)

- U – Bolt up from bottom

- C – Bolt from the top with cover strip

- Up to six meter lengths available

Carriage accessories

Standard carriages are supplied with low friction, double-lip seal and longitudinal side seals

Optional carriage accessories:

- V - Viton® Wiper (532VR)

- Z - Metal Scraper (532ZZ)

- N - Oil Reservoir (532OW)

- C - Bellow Clips (531CC)

Other Accessories

- Stainless steel rail plugs (532 HS)

- Brass rail plugs (532 HB)

- Mylar Tape (532 RT)

- Bolt up from the bottom rail (522 Type U)