Installation Instructions

ProfileRail bearings are generally mounted to structures that are inherently stiffer than the rail. For this reason, the bearings tend to assume the contour of the surfaces to which they are fastened through bearing deflection. When deflection is imposed upon a bearing, especially a preloaded one, resultant forces occur. These forces are transferred to the rolling elements and races, potentially resulting in an increase in system friction and a decrease in system resolution, precision and life.

Various sources can contribute to the overall error of the mounting surfaces. These include the surface flatness of the base surfaces, the location and parallelism of the reference surfaces, and the attendant errors of the bearing as described within the accuracy classes.

The surfaces that contact the base and reference edges may be milled, scraped, ground, or prepared by any other method that will produce a flat mounting surface free of inconsistencies, which would tend to distort or skew the bearing. Dirt and debris should be cleaned off, as they could contribute to the inaccuracies.

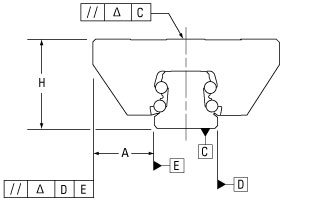

NOTE : All mounting

tolerances should be inclusive of the the rail base to the center of the carriage top (H), and from the rail reference edge to the the carriage reference edge (A) tolerances. Thus, a lower

accuracy class bearing may require a more accurate installation.