Product Details

The ECT and T Series product lines have a number of mounting, feedback and drive accessories.

Mounting Accessories

To be able to mount a

precision linear actuator, the appropriate mounting and adapter options

must be selected. There are several different options to choose from.

However, ECT and T actuators come with mounting holes and T-slots that

can be used.

Mounting accessories available include:

- Mounting feet (T90/ECT90 & T130/ECT130)

- T-slot mounting clamps (T-60 only)

- Trunnion kits

- Spherical joint adapters

- Flanges

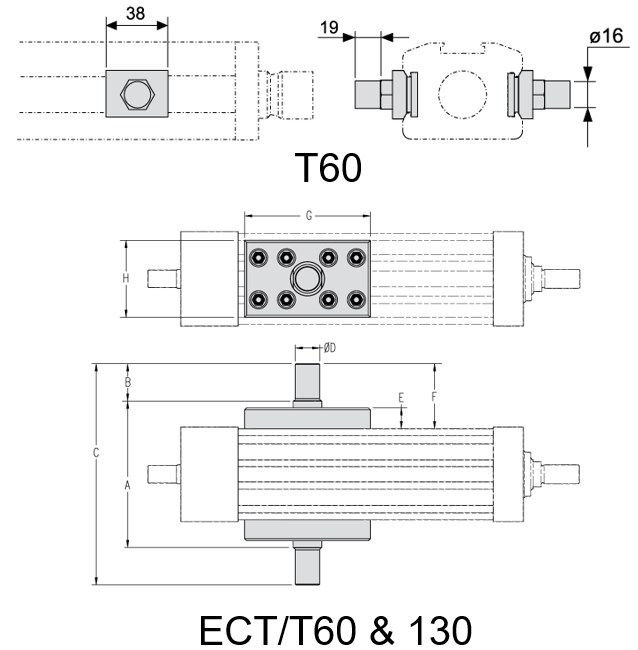

Trunnion kits

The position

along the profile can be adjusted freely by the customer. A trunnion

bracket kit is available separately for T60.

The trunnion accessory can be mounted on the unit from the factory or ordered separately and added later. When ordered separately, all necessary screws to attach the trunnions to the unit are included.

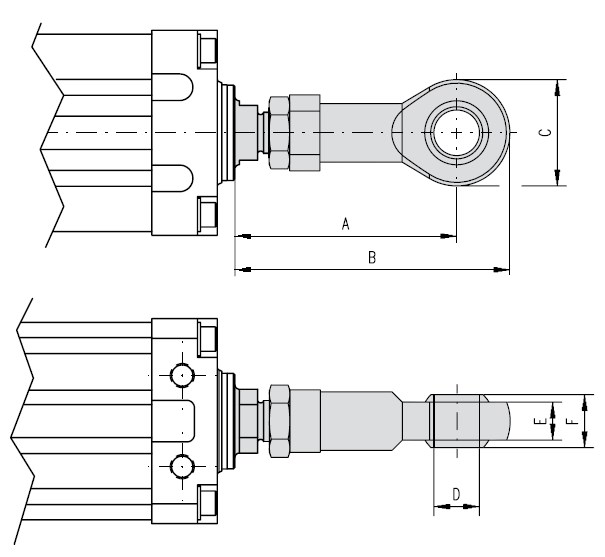

Spherical joint adapters

The

spherical joint option can be mounted on the unit from the factory or

ordered separately. When ordered separately, all necessary components to

attach the spherical joints to the unit are included. Type M joints

include a grease nipple.

Note: When

ordering a spherical joint separately, make sure that the extension tube

end has an outside thread adapter to be able to mount it.

Feedback Accessory - Magnetic Sensor

The magnetic sensors used in the precision linear actuators consist of a reed switch that is molded into a plastic housing. In the actuator, a magnet is mounted that travels back and forth with the extension tube. The magnet triggers the magnetic sensors, which are mounted on the outside of the cover tube. The sensors come in both normally open and normally closed versions.

The magnetic sensors are mounted directly in the sensor slots on both sides of the profile of the units. They require no additional mounting bracket. The sensor is fixed in position by two M3 size locking screws.

Drive accessories (T Series)

For the T Series (units without a motor), some drive accessories are available:

- Worm gear drive

- Adaptor flanges

- Belt gear

Belt Gear

A belt gear consists of a timing belt that runs between two pulley wheels of different diameter. The difference between the diameters determines the gear ratio. Belt gears are quiet, have medium accuracy and require no maintenance. However, the belt is susceptible to breakage under overload conditions.