Design and Theory

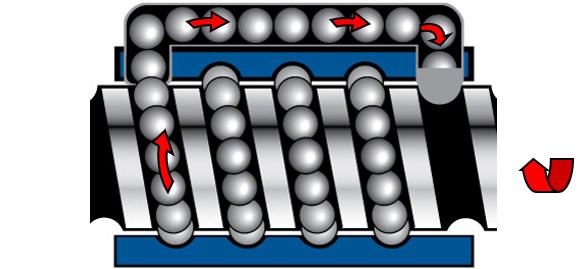

Ball screws convert rotary motion to linear motion and/or vice versa. A

ball screw assembly consists of a screw and a nut with recirculating

ball bearings. The connection between the screw and the nut is made by

ball bearings, which roll in the matching ball forms in the screw and

nut. The forces transmitted are distributed over a large number of ball

bearings, giving a relatively low load per ball. Since Ball screws

assemblies use rolling elements they have a low coefficient of friction .

The following video provides a little detail about ball screws.

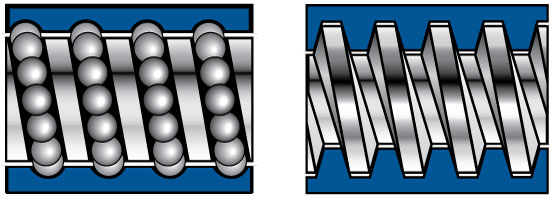

What is the difference between a ball screw and a lead screw?

In

ball screws there are recirculating bearings. In lead or ACME screws

they operate only with sliding friction and do not have recirculating

bearings.

ball screw compared to a lead screw

Ball Screws feature:- 90% Efficient

- Rolling Contact

- Life limited by fatigue - Predictable life

- Lower starting torque

- more load capacity

Lead Screw or ACME screw features:

- 30-80% efficient

- Sliding friction

- life limited by wear - hard to predict life

The following video provides some information on the differences between lead and ball screws. And when one would be better in an application.