Choose Your Login Account

Thomson currently has two account systems - one for the website and CAD model downloads, and one for e-commerce. We understand that two logins is an inconvenience and are working to consolidate our systems into one login process. Until we’re able to consolidate the two logins, please follow these guidelines:

- Download CAD models

- Save and retrieve projects in LinearMotioneering® and MicronMotioneering® tools

- Access Distributor Extranet and all related resources

- Order directly from Thomson online (North America only)

- Authorized Thomson Distributors can view and order from quotes online (Global)

- View the shopping cart and look up prior direct orders

Customer Service Chat (ONLINE) Customer Service Chat (OFFLINE)

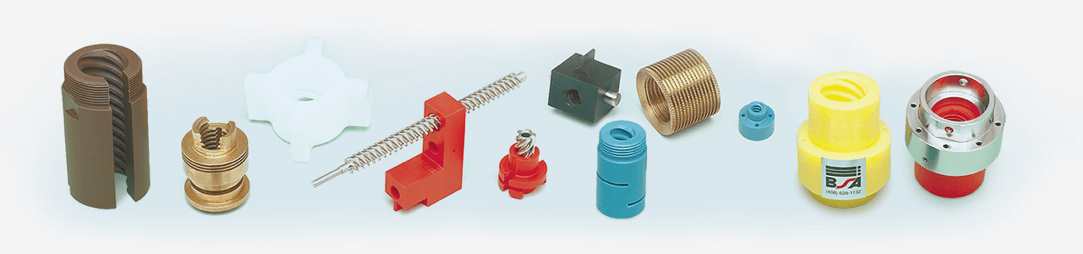

Lead Screws Supernuts

Thomson BSA® precision lead screws are an excellent economical solution for your linear motion requirements. For more than 25 years, Thomson BSA has designed and manufactured the highest quality lead screw assemblies in the industry. Our precision rolling machines ensure accurate positioning to 0.003 in/ft and our PTFE coating process produces assemblies that have less drag torque and last longer.

as small as 2 mm More Details

Select Product Type

Carbon Alloy

Durable ACME screws with a vast size portfolio intended for higher load applications

Stainless Steel

Precision lead screws with very fine accuracy grades and modest load capacities

Miniature Precision

Miniature precision lead screws that are easily configurable for small-scale or space-constrained applications. (Diameters as small as 2mm)

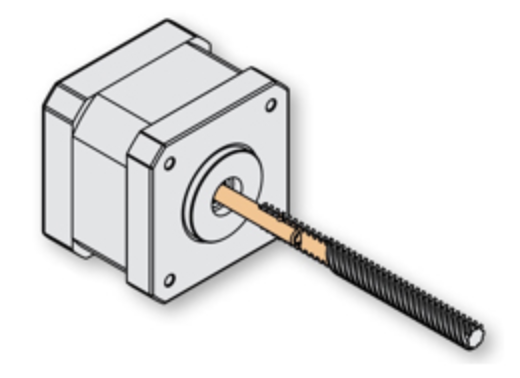

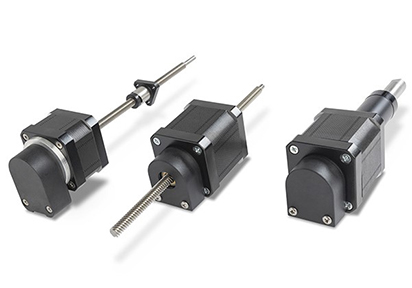

Motorized Lead Screw

Hybrid stepper motor and a precision lead screw in one compact envelope

Thomson lead nuts are only compatible with Thomson lead screws.

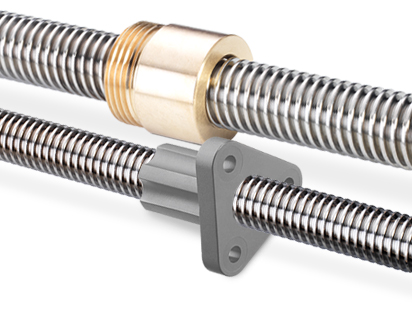

Acme Screw and Nut Assembly

High quality alloy steel screws with precision bronze acme nuts.

Bronze Acme Nut

Anti-wedging nut for smooth, quiet performance.

Acme Screw

Rolled thread screws in wide range of diameter and lead combinations.

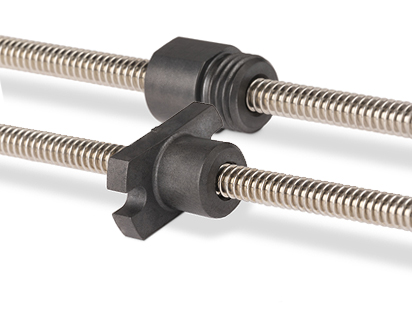

Lead Screw and Lead Nut Assembly

Lead screw assemblies with standard or anti-backlash lead nuts.

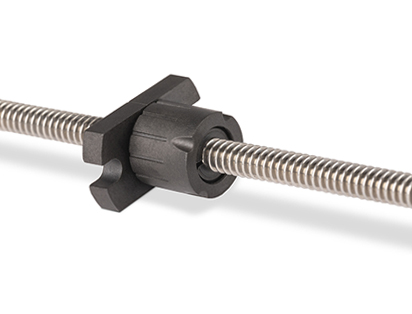

Lead Nut

Performance lead nuts in various materials and backlash configurations.

Lead Screw

Precision lead screws in many coating configurations, diameters, leads, and lengths.

Standard Backlash

Clearance between screw and nut of up to 0.010 in (0.25 mm)

Anti-Backlash

Preloaded nuts with no play between the screw and nut.

Standard Backlash

Clearance between screw and nut.

Anti-Backlash

Field-adjustable assembly allows removal of play between screw and nut.

Flange Mount

Nut Supplied with flange for easy installation.

Thread Mount

Configuration allowing nut to be mounted by threading directly into assembly.

Standard Backlash

Clearance between screw and nut.

Anti-Backlash

Field-adjustable assembly allows removal of play between screw and nut.

Standard Backlash

Clearance between screw and nut.

Anti-Backlash

Field-adjustable assembly allows removal of play between screw and nut.

Standard Accuracy (SRA)

Standard grade screws with an accuracy of up to 0.010 in/ft (250µm/300mm).

Precision Accuracy (SPR)

Precision grade screws with an accuracy of up to 0.003 in/ft (75µm/300mm).

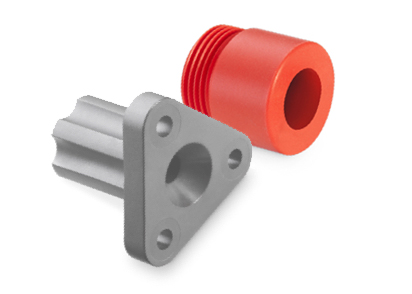

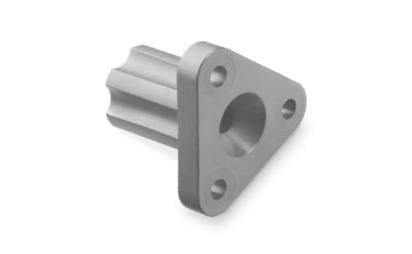

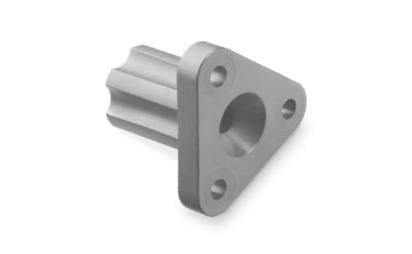

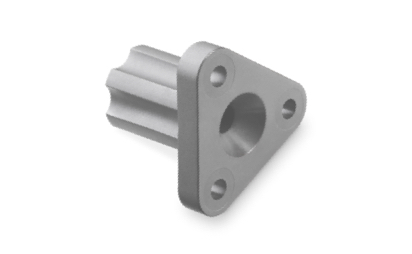

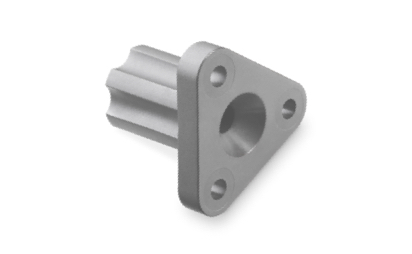

Flange Mount

Configuration allowing nut to be mounted by threading directly into assembly. Metric and imperial threads available.

Thread Mount

Configuration allowing nut to be face mounted with standard fasteners. Triangular, circular, and rectangular flange options available.

Flange Mount

Nut Supplied with flange for easy installation.

Thread Mount

Configuration allowing nut to be mounted by threading directly into assembly.

Flange Mount

Nut Supplied with flange for easy installation.

Thread Mount

Configuration allowing nut to be mounted by threading directly into assembly.

Flange Mount

Nut Supplied with flange for easy installation.

Thread Mount

Configuration allowing nut to be mounted by threading directly into assembly.

Flange Mount

Nut Supplied with flange for easy installation.

Thread Mount

Configuration allowing nut to be mounted by threading directly into assembly.

Flange Mount

Nut Supplied with flange for easy installation.

Thread Mount

Configuration allowing nut to be mounted by threading directly into assembly.

Compact, dynamic loads up to 75 lbf

Compact nut in bearing grade Acetal with a triangular mounting flange. For lead screws up to 0.375 in or 10 mm diameter.

Compact, dynamic loads up to 150 lbf

Compact nut in bearing grade high performance PEEK with a triangular mounting flange. For lead screws up to 0.375 in or 10 mm diameter.

Large form factor

Bearing grade Acetal nut with a triangular or round mounting flange. For up to 0.75 in or 20 mm diameter screws.

Low friction, imperial mount threads

Bearing grade Acetal nut with imperial (inch) mounting threads.

High capacity

Bearing grade bronze nut with imperial (inch) mounting threads.

Metric mount threads, > 4 mm diameter screws

Bearing grade Acetal nut with metric mounting threads.

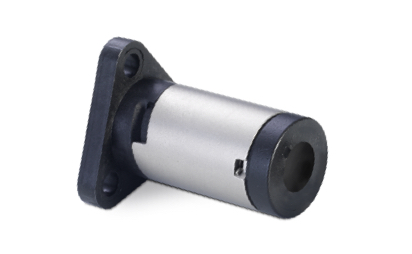

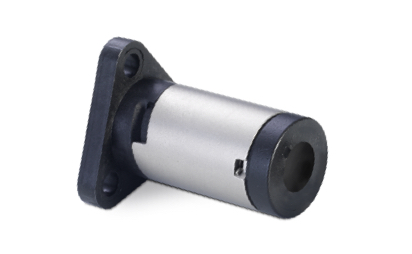

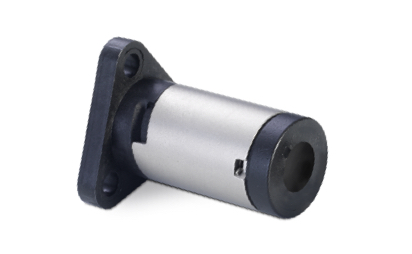

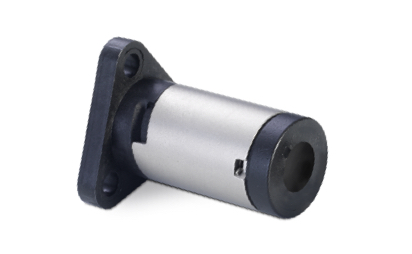

High stiffness, low drag

Flange mount nut with high axial stiffness, low drag, and active wear compensation.

Moderate loads

Flange mount nut with a design loads of up to 25 lbs (111 N).

High stiffness, low drag

Imperial or metric thread mount nut with high axial stiffness, low drag, and active wear compensation.

Design flexibility, large offering

Customizable thread mount nut with a spring pre-load of up to 20 lbs (89 N).

Compact, dynamic loads up to 75 lbf

Compact nut in bearing grade Acetal with a triangular mounting flange. For lead screws up to 0.375 in or 10 mm diameter.

Compact, dynamic loads up to 150 lbf

Compact nut in bearing grade high performance PEEK with a triangular mounting flange. For lead screws up to 0.375 in or 10 mm diameter.

Large form factor

Bearing grade Acetal nut with a triangular or round mounting flange. For up to 0.75 in or 20 mm diameter screws.

Low friction, imperial mount threads

Bearing grade Acetal nut with imperial (inch) mounting threads.

High capacity

Bearing grade bronze nut with imperial (inch) mounting threads.

Metric mount threads, > 4 mm diameter screws

Bearing grade Acetal nut with metric mounting threads.

High stiffness, low drag

Flange mount nut with high axial stiffness, low drag, and active wear compensation.

Moderate loads

Flange mount nut with a design loads of up to 25 lbs (111 N).

High stiffness, low drag

Imperial or metric thread mount nut with high axial stiffness, low drag, and active wear compensation.

Design flexibility, large offering

Customizable thread mount nut with a spring pre-load of up to 20 lbs (89 N).

Examples of Applications

Engraver

Lab

Medical

Semi

Design, Installation and Maintenance Notes

Assembly Configuration

Mini Lead Screws

Glide Screws

XC Advanced Anti-Backlash Supernuts

AFT Advanced Anti-Backlash Supernuts

SNAB Anti-Backlash Nuts

MTS Flange Mount Supernuts

SN Thread Mount Supernuts

SB Metric Thread Mount Supernuts

BN Bronze Thread Mount Supernuts

Lead and Acme Screws

V-Thread Screws

Carbon Alloy Acme Lead Screws

Why Thomson Lead Screws?

No other linear motion component combines the speed, accuracy, efficiency, repeatability, quiet operation, lubrication retention, load capacity, and compactness of Thomson lead screws. Our lead nuts are available in a standard threaded or flanged mounting configuration, and anti-backlash nuts provide the best positional repeatability.Customization Options

Not every linear motion design can meet the optimal specifications by using standard lead screws. In these cases, Thomson offers its engineering services to help you customize lead screws to meet your exact requirements and keep your project running smoothly.Where can you get started?

Thomson provides extensive online resources to help you no matter where you may be in the purchase decision process:VIDEO: Everything You Need to Know to Properly Size and Select Lead Screws for Your Linear Applications

Why are lead screws such a popular choice for precision linear applications? Learn not only their long list of benefits but how you can put these components to work for your design projects and applications.

Presenter: Saurabh Khetan, Product Line Manager - Lead Screws, Thomson

VIDEO: Lead Screw vs. Ball Screw Technology

Jeff Johnson, Thomson Screw Product Engineer, says ball screws and lead screws can sometimes be used in the same applications. Typically, ball screws are used in industry applications that need a lot of load or life while lead screws are used in smaller, lighter duty applications. Lead screws however are highly customizable with the ability to interchange leads, sizes, nut configurations quickly. Cost is usually not the primary consideration when selecting a screw technology. Watch this video to learn the differences.

VIDEO: The Thomson Glide Screw™ – What’s the Buzz All About?

VIDEO: How to Install an XC Lead Nut

For proper performance of your XC lead nut, installation steps for its five components must be followed closely.

Technical Articles

-

Why Lead Screws are the Best Fit for Many Linear Motion Applications - and How to Rightly Apply Them

Ball screws are often viewed as the first choice for linear motion applications because the use of recirculating ball bearings provides a high level of efficiency, load capacity and positioning accuracy. However, with careful attention to selection and application, lead screws can deliver efficiency that comes close to ball screws on many applications, high levels of load capacity and very good positioning accuracy

Learn More -

Why Lead Screw Motor Connection Methods Matter

Which motor is right for your lead screw application? A properly integrated lead screw and motor can cut costs, boost performance, simplify maintenance and provide greater prototyping flexibility. Three of the most common approaches include implementing an external shaft coupling; permanently or semi-permanently fusing the lead screw and the motor shaft together; and using detachable connections. This article covers the key considerations when comparing these options.

Learn More -

Lead Screws Q&A – Application Considerations

This article answers five key questions about specifying lead screws for your linear motion applications.

Learn More

Brochures

| BSA Lead Screws | 1455 KB | |

| BSA Lead Screws | 1463 KB | |

| BSA Lead Screws | 1484 KB | |

| BSA Lead Screws | 2713 KB | |

| Miniature Lead Screws | 1372 KB | |

| Miniature Lead Screws | 5121 KB | |

| Miniature Lead Screws | 1760 KB | |

| Stepper Motor Linear Actuators | 11778 KB | |

| Stepper Motor Linear Actuators | 9252 KB | |

| Stepper Motor Linear Actuators | 4289 KB | |

| Stepper Motor Linear Actuators | 3629 KB | |

| Miniature Components and Systems | 6871 KB | |

| Miniature Components and Systems | 6862 KB | |

| Miniature Components and Systems | 1603 KB |

Catalogs

Technical Articles

| + Lead Screw Assemblies | |||

| Lead Screw Assemblies - Inch |  |

— | — |

| Lead Screw Assemblies - Metric |  |

— | — |

| Mini Lead Screw Assemblies (< 4mm diameter) |  |

— | — |

| + Lead Screw Nuts | |||

| Lead Screw Nuts - Inch |  |

— | — |

| Lead Screw Nuts - Metric |  |

— | — |

| Mini Lead Screw Nuts (< 4mm diameter) |  |

— | — |

| + Screws | |||

| Lead Screws - Inch |  |

— | — |

| Lead Screws - Metric |  |

— | — |

| Mini Lead Screws (< 4mm diameter) |  |

— | — |

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].