Design and Theory

While on the surface, shafts may appear the same, there are significant performance differences due to the

manufacturer’s selected standards and the manufacturing processes used

to achieve them.

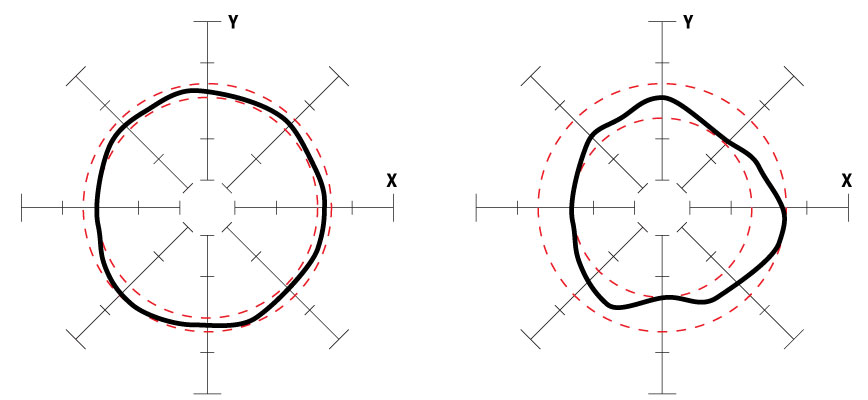

Roundness

Shaft roundness is vital for linear applications such as spindles

and guide rods where accuracy, life or precision is paramount. Roundness

ensures uniform distribution of bearing loads for maximized bearing

life, longer travel life and improved positional accuracy.

Round

shafts can be deceiving to the eye and appear anything but round when

properly evaluated using precision tracing techniques.

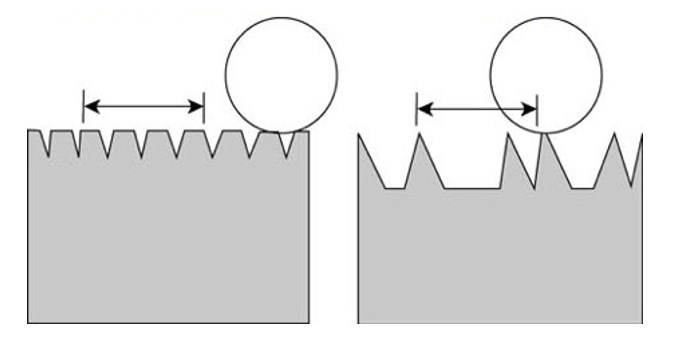

Surface finish

Surface finish is a key factor affecting travel life, load levels, frictional

resistance and smoothness of travel. Industry leading cataloged

surface finish is of 8 Ra max. Excellent surface finish and hardness

maximize the efficiency and life of linear bearings, shaft riding seals and overall visual appearance.

Straightness

Straightness is the most vital parameter to positioning accuracy for a

Linear guide system. The image below shows a typical method for measuring straightness. With the shaft supported at two points 0.2 times the length from the ends, the shaft is rotated and the total deviation indicated is recorded. Beware that even if a shaft is straight when it is made, handling or machining of shafting can cause

the material to bend once it leaves the factory. Care to preserve or restore shaft straightness before installation may be necessary.

Cylindricity

Cylindricity is a measure of the degree of conformance of the outside

surface (diameter along the length of the shaft) to a true cylinder.

True conformance (high cylindricity) ensures the benefits of roundness,

diameter and straightness are present over the shaft length, or working

surface, and not just in a particular location. This ensures uniform

distribution of bearing loads, increases load capacity in the working

area of the bearing, maximizes bearing life, and increases travel life.

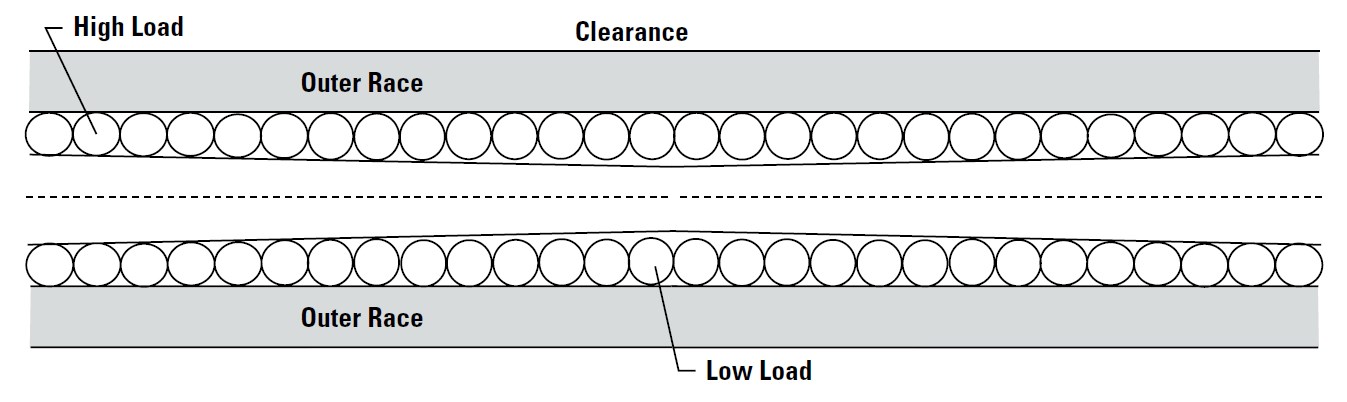

Taper

Taper is a component of cylindricity. In linear bearing applications,

taper can cause one portion of the linear bearing to be loaded higher

than the other. This can cause dramatic reduction in travel life or load

capacity. As taper increases, balls go in and out of preload, causing

premature wear and reduction in travel life.