Design and Theory

When the actuator reaches the end of stroke it needs to stop or risk overloading and damaging itself. There are several ways to protect the actuator from overload when at end-of-stroke which include:

- Clutch

- Electronic load monitoring

- Limit switches

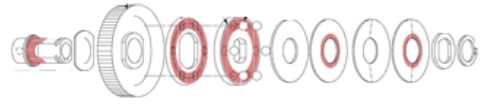

Clutch

Another form of protection can come from simply including a clutch that

will slip when the actuator hits the end of stroke. Simple and

effective. But the system must be designed so that power is not

maintained after the end of stroke is hit or the clutch will quickly

wear out.

Electronic load monitoring

A built-in microprocessor monitors performance of the actuator and will stop the movement at the end of stroke.

Limit Switches

Limit switches prevent damage by stopping the motor if the location of the actuator is at a certain point (Limit). There are three basic classifications of limit switches: end of stroke, adjustable or programmable.

- End-of-stroke limit switches: Prevent damage to the actuator by cutting off power to the motor to prevent the actuator from moving beyond the maximum and minimum positions.

- Adjustable limit switches: Limit switches that can be moved to different locations along the actuator to set limits that are within the maximum stroke of the actuator.

- Programmable limit switches: Stroke limits can be set to limit the stroke in operation to a value lower than the full stroke of the actuator. These can be programmed in the control system of the actuator.