Choose Your Login Account

Thomson currently has two account systems - one for the website and CAD model downloads, and one for e-commerce. We understand that two logins is an inconvenience and are working to consolidate our systems into one login process. Until we’re able to consolidate the two logins, please follow these guidelines:

- Download CAD models

- Save and retrieve projects in LinearMotioneering® and MicronMotioneering® tools

- Access Distributor Extranet and all related resources

- Order directly from Thomson online (North America only)

- Authorized Thomson Distributors can view and order from quotes online (Global)

- View the shopping cart and look up prior direct orders

Customer Service Chat (ONLINE) Customer Service Chat (OFFLINE)

Not finding the precision linear actuator you need? Contact us for a custom solution!

Family

Motor Type

Drive Type

Dynamic Load

Maximum Linear Speed

Brake

Resolver

Stroke

Mounting Options

Adapter Options

Travel per Shaft Revolution

Number of Normally Closed Sensors

Number of Normally Open Sensors

Screw Diameter

Profile Size

Protection

Compare

3D Model

Family

T Series

The proven design of the T series precision linear actuators has found its way into thousands of applications throughout the world. Precision-rolled ball screws provide smooth motion, accurate positioning and quiet operation while the slide guide bushings and the rugged exterior design allows it to be used in the thoughest applications. The T series combines durability, performance and ease-of-use with a large selection of factory-engineered options and accessories. Regardless of the environment or requirement, we can customize our standard models to fit just about any application.

ECT Series

The ECT series is our line of packaged precision linear actuators. They are based on the proven T series and equipped with a high quality selection of motors and gears that make them ready to take on the most demanding applications. The ECT series is ideal when short design times, maximum performance and the longest life cycle are required. And if you can‘t find a standard unit that fits our engineers can build you a customized unit to suit just your needs.

PC Series

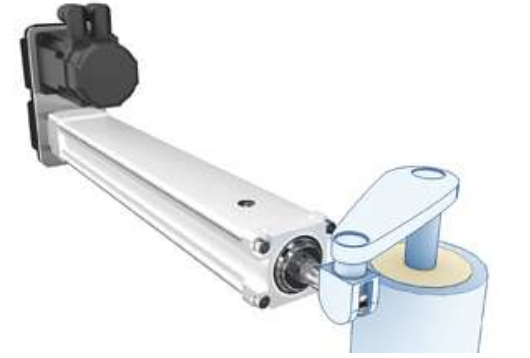

The design of a PC-Series™ precision linear actuator delivers extended life, high repeatability, and quiet operation. In addition, it requires minimal maintenance and resists corrosion in harsh environments.

Motor Type

The motor type (if any) of the precision linear actuator.

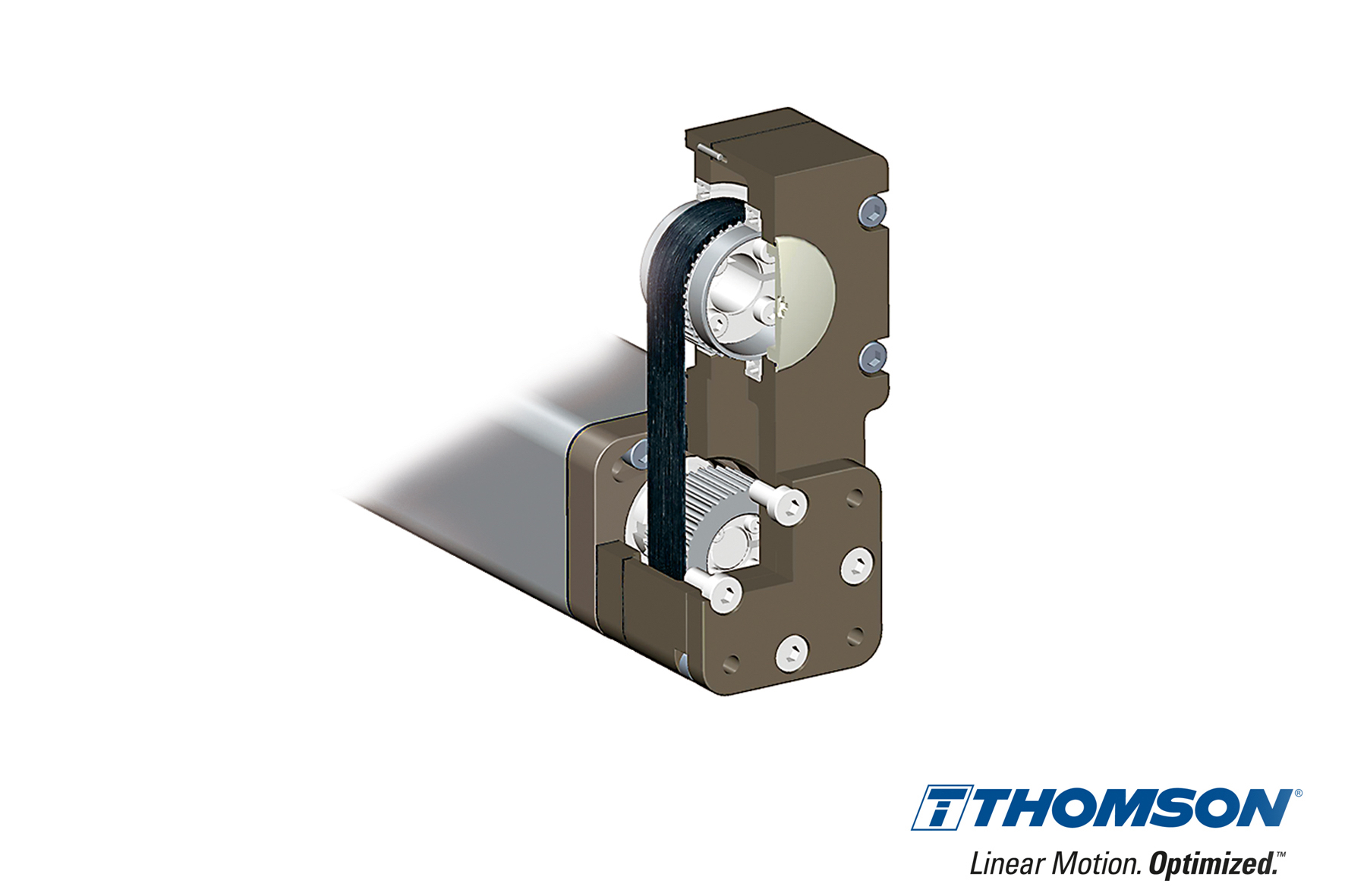

Drive Type

The manner in which the motor turns the screw inside the unit.

Dynamic Load

The dynamic load rating is the maximum load the actuator can move at a given speed. The relation between the the dynamic load and the speed can be studied in the speed versus load diagrams. For some actuators however, the column load limit will be exceeded if the extension tube extends beyond a certain point.

Maximum Linear Speed

The maximum allowed speed at any given dynamic load ranging from no load to maximum allowed dynamic load. For some actuators however, the critical speed limit can be a limiting factor for the maximum allowed speed if the extension tube extends beyond a certain point.

Brake

Brake type, if any.

Resolver

A resolver is basically a type of rotary electrical transformer used for measuring degrees of rotation and are commonly used on AC servo motors as a feedback device to control the commutation of the motor windings. The resolver is mounted to the end of motor shaft and when the motor rotates the resolver will transmit the position and direction of the rotor to the servo drive which then can control the motor. Most servo drives for AC servo motors on the market today can convert the resolver signal in to a pulse train (encoder signal simulation) which can be used by a motion control to determine and control the position of the motor.

Stroke

Mounting options to mount the cylinder to the customers machine.

Mounting Options

Adapter Options

Options for the rod end of the actuator.

Travel per Shaft Revolution

How far the cylinder will advance with one full turn of the input shaft or motor.

Number of Normally Closed Sensors

The magnetic sensors used to the precision linear actuators consist of a reed switch that are molded into a plastic housing. In the actuator a magnet is mounted that travels back and forth with the extension tube. The magnet triggers the magnetic sensors which are mounted on the outside of the cover tube. The sensors come in both normally open and normally closed versions.

Number of Normally Open Sensors

The magnetic sensors used to the precision linear actuators consist of a reed switch that are molded into a plastic housing. In the actuator a magnet is mounted that travels back and forth with the extension tube. The magnet triggers the magnetic sensors which are mounted on the outside of the cover tube. The sensors come in both normally open and normally closed versions.

Screw Diameter

The nominal diameter of the screw inside of the actuator.

Profile Size

Roughly the outside cross section dimensions of the actuator cylinder.

Protection

The protection class refers to the environmental rating of the enclosure. The first digit applies to airborne contaminants and the second digit to water/moisture. IP65: dust tight and protected against low pressure water jets from any direction.

Customer Service

This part number is not available for sale online but may still be available for sale. Click here to contact Thomson Customer Support.

Customer ServiceOverview

Standard Precision Linear Actuators

Custom Precision Linear Actuator Options

Optimize your design with a custom precision linear actuator solution.

Why Thomson Precision Linear Actuators?

Thomson precision linear actuators offer the longest stroke lengths in the industry, a simple and reliable RediMount™ system to mount your own motor, and product customization options. These actuators draw energy only on demand and operate more quietly than pneumatics. All precision linear actuators are designed to require a minimum of maintenance. There are no parts that need to be replaced due to wear, and regular lubrication is needed only in applications where the actuator works hard and frequently.

Customization Options

Customization is one of our strengths, and we have built countless one-of-a-kind units. If you need a special stroke, a unique mounting bracket, or some other adaptation of the standard product, our engineers will help you find the perfect solution for your application.Where Can You Get Started?

Thomson provides extensive online resources to help you no matter where you may be in the purchase decision process:

VIDEO: Introducing PC Series Electric Actuators

Explore new technology optimized for pneumatic to electric conversions to reduce energy costs and simplify your machine design. The detailed technical overview in this video illustrates how the new PC Series can deliver improved power density, travel life and side load capabilities not found elsewhere.

Replace Pneumatics with Electric Actuators

Next generation machines and equipment need to be more compact while delivering higher performance and more flexibility. Making the change from pneumatic cylinders to electric actuators can simplify your design and deliver savings at the same time. In this webinar learn why to use PC Series actuators over pneumatic cylinders; key Features and benefits; technical data and performance curves; application examples; and how to select the right product and ordering information.

Presenter: James Marek, Business Unit Director, Linear Systems, Thomson Industries

VIDEO: Precision Linear Actuators 101 – Basics for Design Engineers

This webinar is a basic introduction to precision linear actuators. You will learn: What is a Precision Linear Actuator (PLA); Typical Applications; and Sizing & Selection.

Presenter: Kyle Thompson, Associate Product Line Manager – Linear Systems

-

Choosing Between Electromechanical and Fluid Power Linear Actuators in Industrial Systems Design

The type of actuator used plays a critical role in the machine’s performance, initial cost and operating costs. This article will look at the pros and cons of each of the main types of linear actuators with the goal of providing a general guide for their selection and application.

Learn More -

Technology and Design Advances Drive Trend Towards Electromechanical Actuation

Over recent years, there has been an increase in demand to increase the use of electric rod style actuators and reduce the use of pneumatic actuation in factory automation equipment. This article examines the numerous factors driving this conversion.

Learn More

Brochures

| PC Series Precision Linear Actuators | 2359 KB | |

| PC Series Precision Linear Actuators | 2360 KB | |

| PC Series Precision Linear Actuators | 2337 KB | |

| PC Series Precision Linear Actuators | 1855 KB | |

| PC-Series Precision Linear Actuators | 2162 KB | |

| Precision Linear Actuators | 754 KB | |

| Precision Linear Actuators | 410 KB | |

| Precision Linear Actuators | 2215 KB |

Catalogs

| Precision Linear Actuators | 4533 KB | |

| Precision Linear Actuators | 4514 KB | |

| Precision Linear Actuators | 4617 KB | |

| Precision Linear Actuators | 4545 KB |

Calculation Support

Manuals

Technical Articles

| ECT Series |  |

— | — |

| T Series |  |

— | — |

| PC Series |  |

— | — |

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].