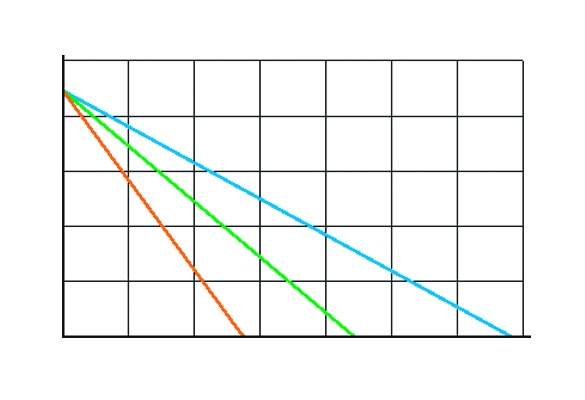

Lead screw performance is largely a factor of axial load and rotational speed (rpm). The relationship between the two is governed by the 'Pressure Velocity' or PV curve. Because lead screws operate using sliding surfaces to support the loads, heat is generated by the friction between the nut and the screw. Wear also occurs between these surfaces. The PV curve defines the safe operating limits of load and speed. As load increases, the rotational speed must be reduced to prevent excessive heating and wear from occurring. The reverse is also true. It is possible to turn the screw at high speed while applying a light load or move slowly under a heavier load. It should be noted that the travel per revolution, frequently defined as the 'lead', can be increased to increase the linear speed without increasing the required rpm. This is a good way to increase the life of a lead screw. In order to size a lead screw system it is important to know what torque will be required to drive the load. This can be calculated simply once the efficiency if the lead screw is known. The more travel per revolution, the higher the required torque but the efficiency also increases, up to a point.

You can contact our Application Engineering team for further assistance selecting the appropriate lead screw or ball screw product for your application.