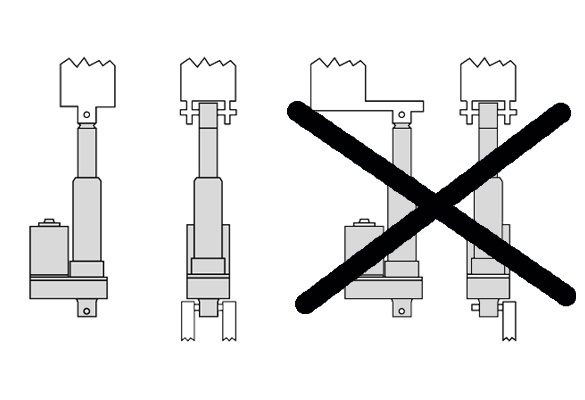

Side loading is when force is applied to the actuator radially, rather than along the axis of extension. It can be generated from an unsupported offset load, insufficiently fixed mounting, or external loads pushing against the actuator, for example.

Side loading pushes the actuator's components out of alignment. The extension tube rubs against the cover tube. The ball nut doesn't ride smoothly along the screw. The gears can even be damaged. It can cause significant, irreparable damage to your actuator through binding.

All loads on Industrial Linear Actuators should be inline with the extension axis of the unit, as discussed in the installation manual for your actuator and the 'Mounting' section of the Thomson Linear Actuator catalog glossary.

The Precision Linear Actuators are designed for some side load and have extra bearing support for the extension tube.