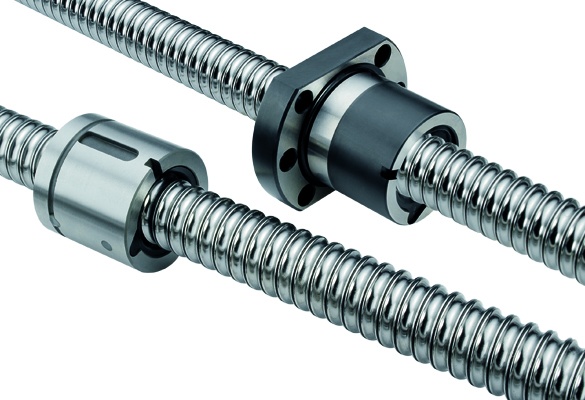

Rolling is preferred over cutting (turning on a lathe) for lead screws. It involves pressing a round bar between a set of dies that roll the threads into it. It results in a harder surface with superior surface finish for lead screws. Rolling is also the most common process for ballscrews because it is more economical and sufficiently accurate for most industrial applications. Lead accuracy can be held to better than .003 inch/foot and longer lengths are possible than with ground screws.

If higher accuracy is required, grinding should be considered. The grinding process can hold lead accuracy’s as tight as .0003 inch/foot or better. However, this process is much more expensive and the maximum length of screw is much shorter.