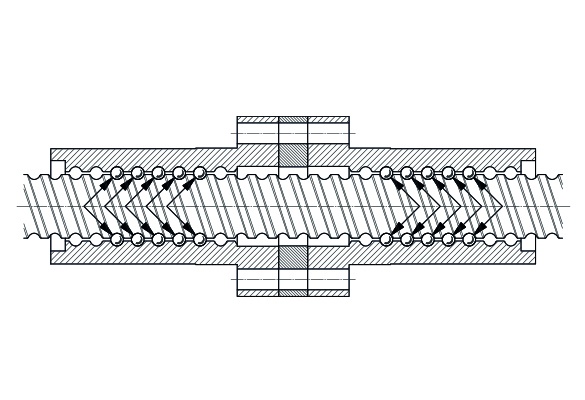

Backlash is caused by the clearance between the ball bearing elements and the screw and nut tracks resulting in lost motion in the screw. A ball nut with all the backlash removed is called preloaded. There are several ways to reduce or eliminate the backlash in a ball screw assembly:

At the factory level we can select ball sizes to minimize the backlash. This works well for small lead to diameter ratios, like a 5x25mm. In some cases we can preload a ball nut in this way. The only way we can guarantee a preload with this method is to build and ship the screw and nut as an assembly. Larger leads don't run as smoothly using this method.

The other method is to use a ball nut with adjustable preload. These use two ball nuts with a spring assembly between them. The spring assembly presses one nut against the left side of the screw tracks and the other nut against the right side of the screw tracks. These use a threaded ring that adjusts the spring tension between the nuts allowing you to tune the preload to your individual application. This also allows for purchasing the nut and screw separately while still achieving a preload.