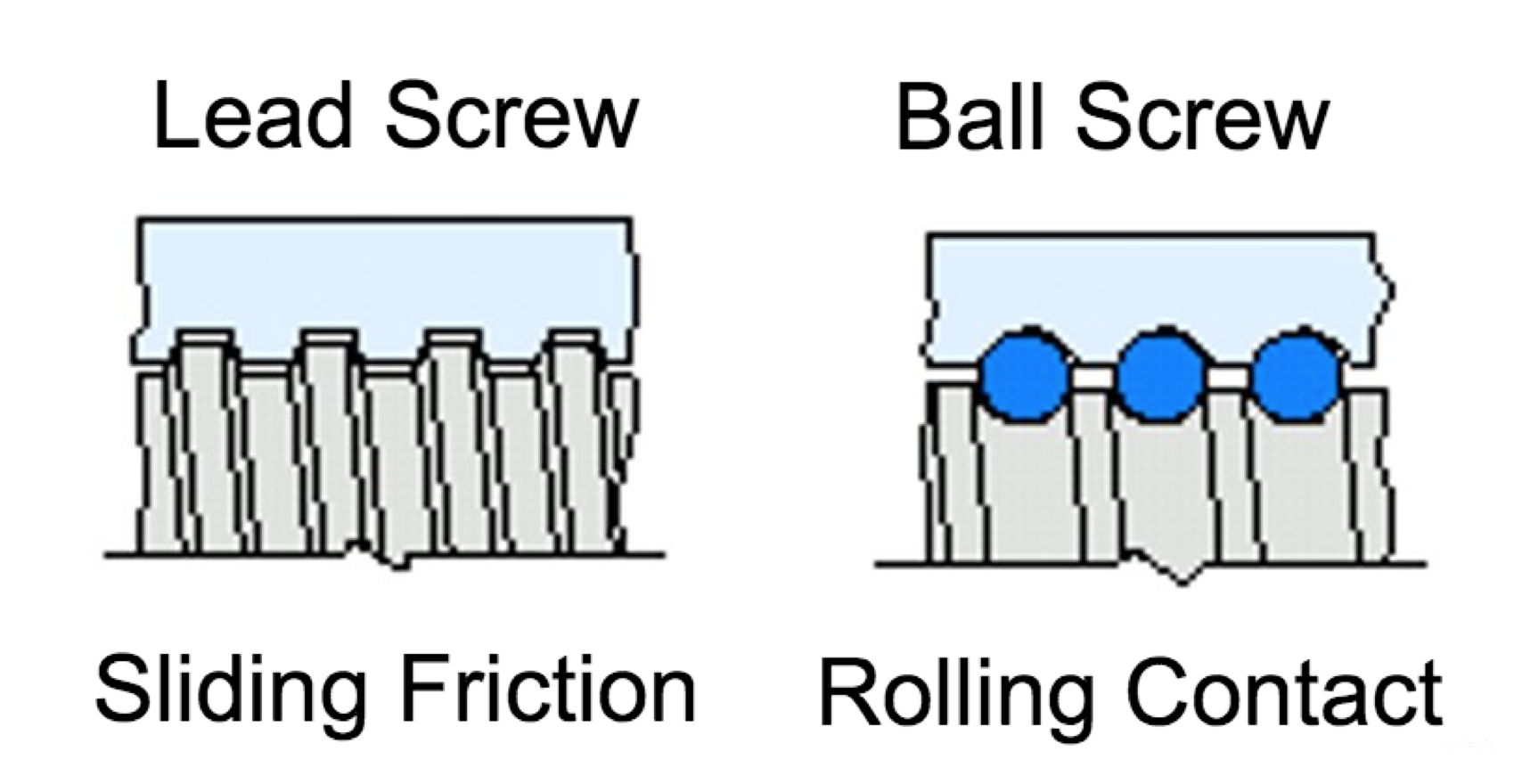

The biggest difference between a ball screw and lead screw is how they carry a load. Ball screws use ball bearings that recirculate to minimize friction and convert rotary motion to linear motion. Lead screws do not use ball bearings and rely on low coefficients of friction between the sliding surfaces. Lead screws, therefore, have higher friction making them less efficient than ball screws.

Lead screws are more suitable for simple transfer applications for which speed, accuracy, precision, and rigidity are not as critical. Ball screws are more suitable in applications where higher loads and faster speeds are needed.

Lead Screws

- Better suited for vertical applications because they can be made to self-lock

- Do not require a braking system

- Move by sliding friction

- 30-80% efficiency

- Lower cost

- Quiet - no ball recirculation

- Can operate with or without lubrication

- More compact and offer greater design flexibility

Ball Screws

- Require a braking system to prevent backdriving

- Heavier load capacities

- 90% efficiency

- Lower starting torque

- Noisier than lead screws

- Requires lubrication

For more on the differences between ball screws and lead screws read: Ball Screw or Lead Screw? Five Questions to Help You Identify the Right Equipment for Your Application