The often-overlooked benefits of integrating high-speed, multi-axis motion on a single shaft

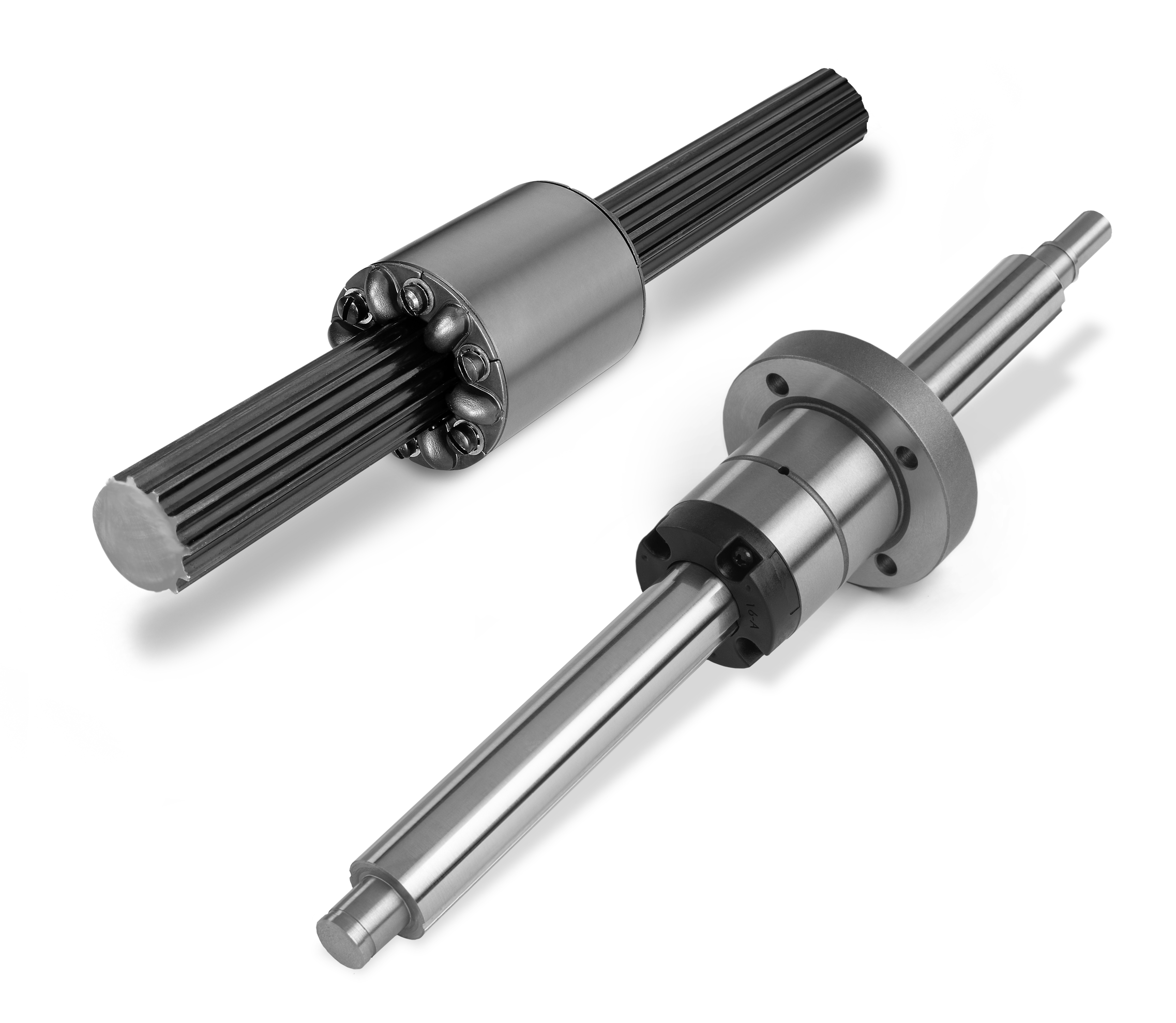

When motion system designers need complex, high-speed and multi-axis motion, they might first think of elaborate, pre-packaged robot arms. Or, if they need only a few axes, they might think of configuring a separate profile or round rail for each axis. But hiding between those options is the simple and proven, yet often forgotten, ball spline technology. This multi-axis motion solution has been around for years and is still highly relevant to many of today’s complex motion schemes. Ball splines use a unique architecture that integrates rotary and linear motion on a single shaft, giving them more flexibility to implement complex motion schemes in tighter spaces, providing a 2-for-1 deal in motion control. (Figure 1)

Figure 1. Ball splines, which enable rotary and linear motion on a single shaft, deliver high reliability and life expectancy under varying operating conditions. Image courtesy of Thomson Industries, Inc.

Integrating rotary and linear motion

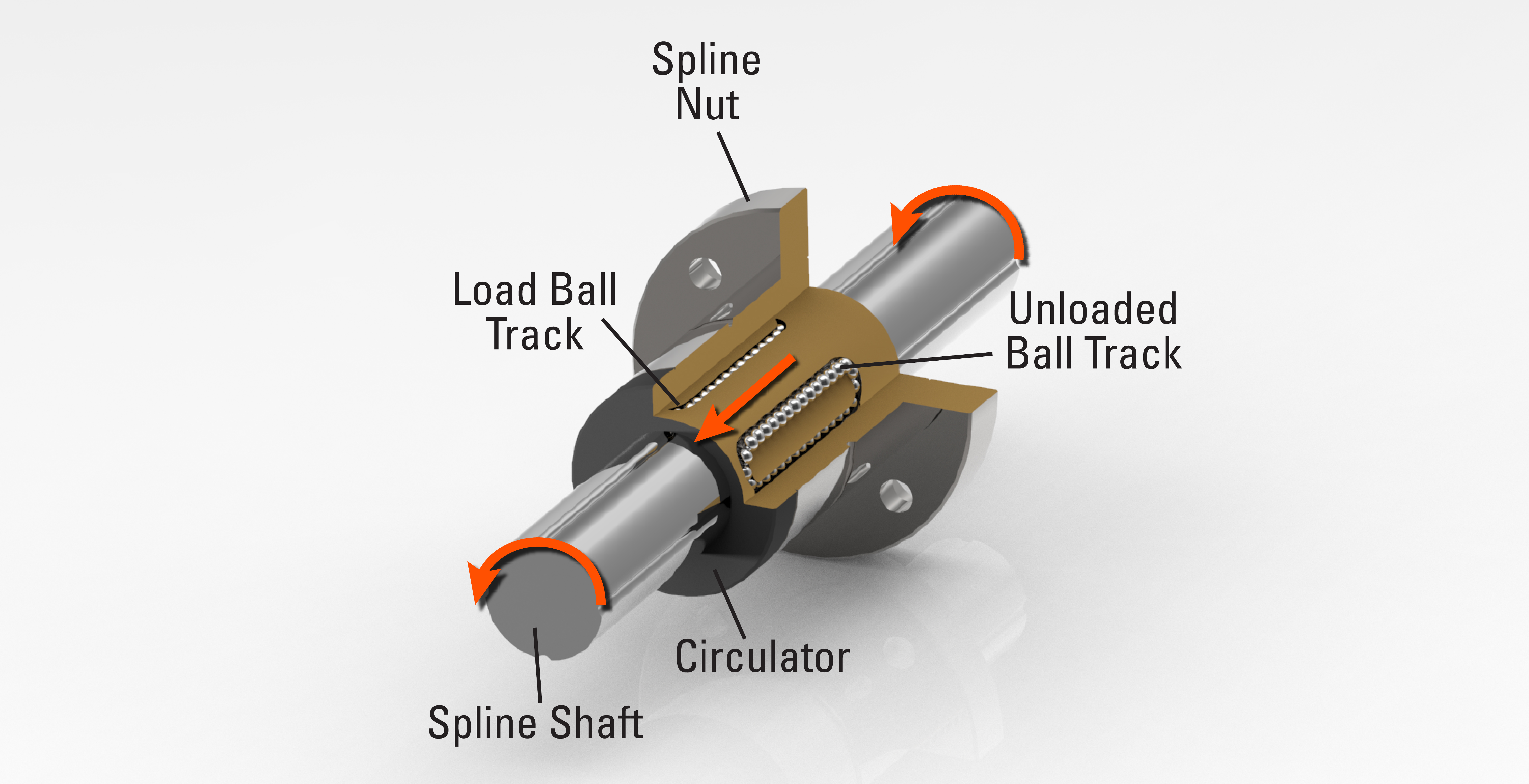

Ball splines allow for the translation of both linear and rotational motion. This is accomplished through the implementation of a common shaft to perform two independent motions. (Figure 2) When viewed, the shaft will include axial ground grooves called “splines” along its length. This arrangement will also include a ball spline nut that rides along the axial ground grooves and locking rotational movement or radial moment loads. Each nut is supported via a bearing and, most often, a common anchoring point like a round tube that is affixed to a bracket supported by the mechanism. Each nut will be independently driven by a motor (often belt driven) responsible for controlling its respective axis of motion.

To drive the axial rotation, the ball spline nut is turned. This nut houses a series of balls that allow for free motion along the axis (i.e., the nut can slide along the shaft with minimal friction). When rotated, these same balls apply a perpendicular force to the shaft via the spline cut grooves, rotating it.

To drive linear motion, the spline shaft is moved forward or backward using a linear actuator, like hydraulic, pneumatic or electric piston. As the spline nut moves along the length of the shaft the ball bearings roll within the grooves. Rolling instead of gliding has a lower coefficient of friction and wear and allows for smooth, precise linear movement and higher velocities. The ball bearings circulate within the nut, providing continuous rolling contact with the shaft.

Because of the anchoring/support, this arrangement is also very resistant to torsional loading (i.e., the shaft resists rotation unless driven by the motor). If a torsional load is applied externally to the shaft as it is extending/retracting/stationary, it is supported by the spline nut and will resist that load. In addition to a “2-for-1” motion deal on the shaft, this feature is as important for its utility in application design.

Accomplishing this on a single shaft has numerous benefits. It provides better space utilization; increases load capacity, speed and accuracy with negligible friction; and improves durability with minimal maintenance.

Figure 2. In enabling both linear and rotary motion on a single shaft, ball splines deliver a host of benefits to robotic designs, including increased compactness, load capacity, speed and accuracy. Image courtesy of Thomson Industries, Inc.

Better space utilization

Compressing multiple axes into one makes ball splines much more space efficient than traditional bearing solutions. This design translates into fewer components and moving parts, and a larger load capability within that space than would be possible with comparable linear bearings.

Higher load capacity

Wide, precision-ground grooves increase load-carrying capabilities, and improve rigidity and stiffness for handling larger moment loads ̶ up to twice as much as traditional bearing assemblies. Ball splines also distribute more load along the length of the shaft. This enables them to carry higher loads than traditional bearings, which may be more subject to localized stress concentrations. Ball splines are also better with off-center loads, such as are common in tool change and pick-and-place applications.

Negligible friction

The ball guidance system provides nearly friction-free motion through precise contact with tangential points of rolling balls guided by spline shaft grooves and the race within the nut.

Higher speeds

Ball splines need only small forces to displace the spline nut axially while transmitting torque and minimizing friction. This contributes to an approximately 20 percent speed increase over a traditional ball screw and smoother operation. Ball splines can handle speeds up to 2 m/s.

High precision and accuracy

Ball splines offer high precision and accuracy in positioning, making them ideal for applications where precise control is required. Zero backlash ensures that there is no rotational play or lost motion when changing directions. Ball splines maintain this precision and low friction even under heavy loads, ensuring accurate and consistent motion.

Easy installation and maintenance

Installation is easy, typically requiring a rough bore and mounting holes drilled and tapped to secure the flanged nut, or a rough bore and keyway for a round nut. The simplicity of their design makes ball splines easier to troubleshoot and maintain. The maintenance team can just pull the spline from the shaft, lubricate it and put it back in, unlike the higher maintenance requirements of profile rail and ball screws.

High durability

Ball splines have a longer service life compared to some traditional bearings due to increased ball-bearing point contacts, which reduces stress and increases load capacity. The less stress on the balls, the heavier the load they can handle while also resisting wear and providing consistent performance over time.

Ball splines can often be designed with seals and protective covers that shield the ball bearings from contaminants like dust and debris, further extending their lifespan. The ball spline architecture has a safe load capacity from every angle, unlike a radial bearing, in which the balls must be positioned appropriately and painstakingly to balance the load.

Cost savings

Upfront savings is substantial for this alternative way of performing the two axis of motion, and the savings multiply in the case of higher volumes. Compared to packaged, multi-axis systems, ball splines are significantly less expensive. They are also more economical than profile rail assemblies because of their small number of components and fewer moving parts. They deliver better moment load resistance for the price and require less surface preparation for installation. Compared to round rail assemblies, ball splines’ cost is similar, but within a smaller footprint and fewer axes. And looking at long term, fewer components would need maintenance so both time and cost savings would be realized.

Applications

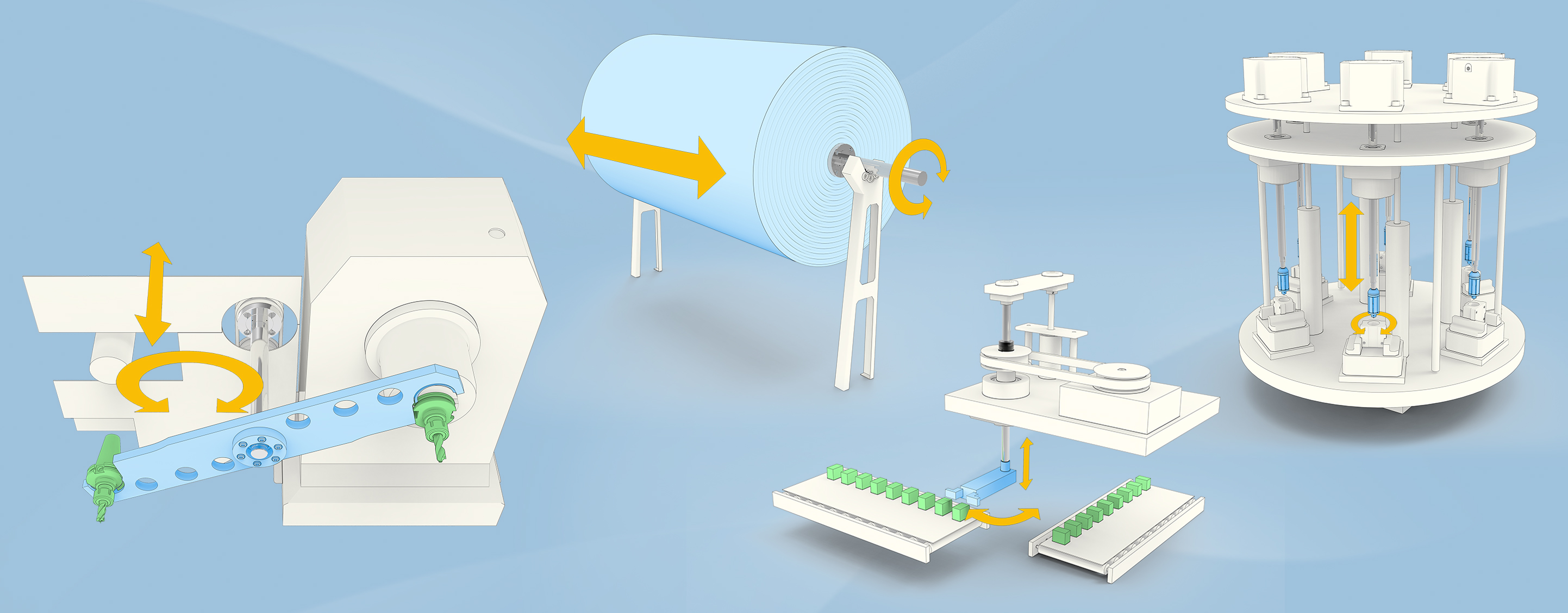

Motion designers integrating both linear and rotary motion should evaluate ball spline technology to see if configuring them on the same shaft would be a benefit. Here are some application examples in factory automation, transportation, and healthcare and research that have taken advantage of ball spline functionality:

Factory Automation

- Repeatable pick and place assembly, such as high-speed semiconductor object positioning in which an arm picks from the assembly stage, rotates and places on another.

- CNC tool positioning in machining and milling operations.

- Packaging equipment for precise control of filling and capping mechanisms.

Transportation

- Aircraft controls, such as flap deployment and throttle adjustment.

- Military vehicles to facilitate rotation, gun elevation and vehicle steering.

Healthcare and Research

- Surgical robots to guide robotic-assisted surgical procedures.

- Medical imaging devices to facilitate the precise motion of CT scanners or other high-precision image acquisition devices.

- Laboratory analysis, such as microscope stage and sample positioning.

The benefits of ball splines make them ideal for a number of applications, including (from left to right) CNC machining, paper mill drums, pick and place, and machine automation. Image courtesy of Thomson Industries, Inc.

To help machine designers optimize ball splines for their applications, some vendors offer online guidance. A ball spline selection tool on the market, for example, uses visual aids that get users to the best configuration in mere minutes.

Finding their place

Ball splines are an attractive solution for machine designers who need motion on multiple axes. Compared to packaged, multi-axis systems, ball splines require less space and can be deployed at higher speeds, with lower friction, greater precision, longer, more predictable life, and easier maintenance. They can also be less expensive.

While a ball spline might replace packaged robotic arms, their space efficiency and zero backlash make them usable as components of those assemblies, possibly extending a vertical stroke or assisting with heavier radial and axial loads.

As business operations become more complex, and digitalization, AI and mobility advancements bring more axes of motion into automation strategies, the ball spline’s unique performance and versatility may, at last, receive the respect it deserves.