Supply chain delays result in longer than expected lead times for motion control components, contributing to rising prices and the inability of machine OEMs to promise delivery. Design engineers are increasingly forced to trade off cost, delivery time, performance and other variables to ensure they have a functioning component capable of meeting their basic design specs in time. They are also, however, finding that real-time collaboration with vendors can be one of their best weapons for optimizing motion system designs across a volatile supply chain.

You want it when?

Today's well-publicized supply chain bottlenecks are changing technology purchasing processes dramatically. The days when a motion control vendor could stand by a quote for a year or more are gone for now, and maybe forever. Nowadays, a design engineer starts a project with an assumed delivery time in mind and plenty of supplier inventory on the shelf, but by the time they are ready to order, the stock may be gone.

Whether such delays are caused by issues with other critical path components or by other factors, they can bump delivery schedules from days to weeks and even months. Faced with the prospect of not getting the exact parts they need in time to meet their customer commitments, designers must often accept tradeoffs between delivery, price, performance and other variables. The challenge is to do so without sacrificing quality.

Real-time collaboration to the rescue

The motion control industry implemented real-time collaboration well before this current supply chain crisis. Machine designers are increasingly spending more time in a virtual 3D world. They are comfortable engaging in real-time collaboration to optimize their designs, streamline purchasing, keep projects on track and add expert perspectives. This has become more relevant over the past few years as the pandemic has forced more people to work remotely. Now, in what many believe is a related supply chain crisis, the value of real-time collaboration is even more pronounced.

Figure 1. Virtual design consultations allow both the motion system designer and vendor engineer to discuss design requirements and how to best reach an ideal solution in real time. (Image courtesy of Thomson Industries, Inc.)

A collaboration session might begin when a motion system designer visits a linear motion website looking for a part. Most websites now have tools that streamline searching and product development, but some offer an immediate, real-time consult with a motion specialist, speeding time to design considerably. (Figure 1) If no instant session is available, many sites will have an online scheduling calendar.

During such sessions, customers and vendors can surmise the motion profile and learn other critical details like the duty cycle, application environment, and commercial information such as time preferences and requirements. Likewise, the vendor can share CAD drawings of standard modules that meet the basic needs and then propose modifications.

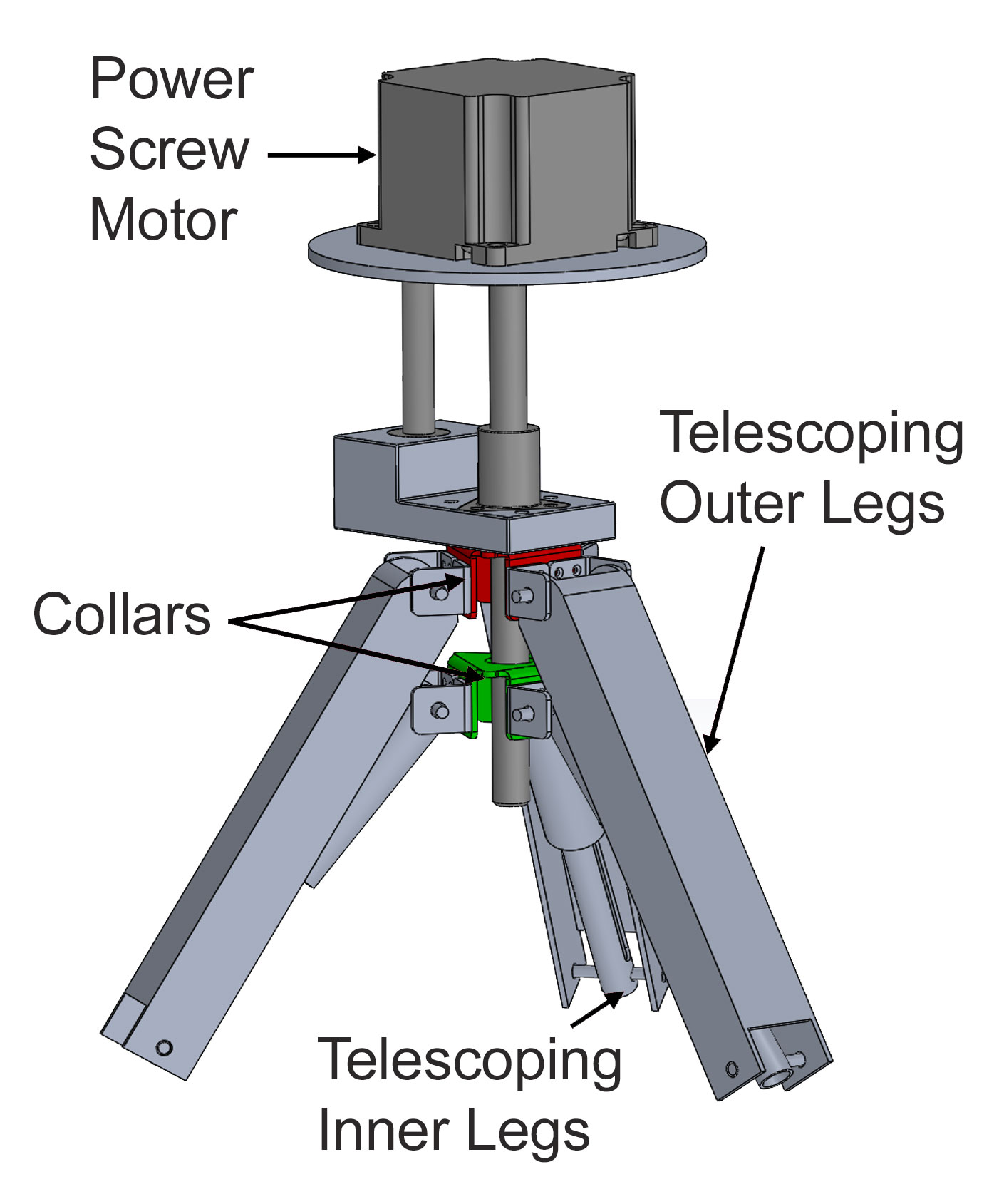

Figure 2. This stepper motor linear actuator assembly enables crutches to automatically stand on their own. A team of designers, interacting in real time online with motion engineers, was able to build a working prototype that included a custom anti-rotational guidance block in a fraction of the time that more traditional methods would have required. (Image courtesy of Waterloo University, FYDP Group 35)

Figure 2 illustrates a sample result of such discussions. This project started with an initial design consultation between a team designing a self-righting crutch under guidance from a linear motion expert from Thomson Industries, Inc. The designers wanted to use a single actuator to enable legs to form a supporting tripod whenever designated events such as letting go of the crutch handle occurred. On the Thomson site, the designers used online design tools to enter basic motion profile information and further refined the design after scheduling a live engineering consulation. The consultation streamlined the process significantly as the engineer was able to quickly view and address the need for custom anti-rotational guidance functionality that might have taken those without advanced linear motion expertise a long time to figure out on their own.

If the customer needs to bring colleagues into the process, they can use online calendars to schedule group sessions with colleagues. This approach is valuable in pinpointing the impact of tradeoffs on other members of the machine builder's team. Likewise, it gives the vendor engineer more opportunity to involve colleagues who might have complementary specialties.

Further improving this process’ communications, real-time collaboration enables augmentation of the virtual 3D models with cameras that can show the application that will host the motion products.

Managing the tradeoffs

Tradeoffs might include price, delivery time, select elements of the motion profile or any aspect of the project that may be contributing to the delay. The benefits of collaborating with a motion control expert in real time are especially evident in situations in which multiple elements of the configuration must change for maximum optimization. If the expected project load is heavier than the standard model allows, the vendor engineer can provide various options to boost it. They might suggest, for example, different gearing or screw lead, or altering the mechanical advantages. Or, if the customer wants position feedback, the vendor can help sort through the numerous options and their impact on the schedule. The solution might include opting for an available smart linear actuator. All adjustments could be in real time, so customers can instantly visualize each choice's impact on the overall motion performance.

Many tradeoff discussions involve customized products. Suppose the customization is extending the lead time. In that case, the customer and vendor engineer can work together to compare the features and benefits of a standard product that may have a shorter lead time. The customer may, for example, have specified a product with high temperature resistance that requires a high-temperature grease but must now evaluate whether the high-temperature capability is more important than having the part sooner. Or, if a particular connector is contributing to the long lead time, they may determine whether the expected benefit is more important than the delivery time.

Sometimes the customer may be looking for customizations specifically to accelerate time-to-market. They may, for example, order an actuator that is longer than their motion profile requires just because it can be installed and mounted quickly without modifying the host system. The vendor expert would help them evaluate and understand its potential impact on cost, performance and delivery schedules. If the customization does extend the timeline, the vendor may ship standard units the customer can use to validate concepts while the vendor builds out the customized units.

In most cases, the vendor engineer can present a good-better-best set of options for the customer. To a customer wanting to increase stiffness on a polymer bushing bearing they were considering, the vendor engineer might suggest a $2000 profile rail with slightly higher stiffness available in a week or a $4000 rail with maximum stiffness for delivery in six weeks.

Vendor responsibilities

Just as customers are responsible for providing accurate information on their motion requirements and application environments, vendors must come to the table with precise lead times for each solution based on a realistic assessment of their respective supply chains.

Vendors should also work closely with buyers on release schedules, understanding exactly what the customer may need and when. If they can't deliver the entire order on time, they may be able to ship enough partials to meet immediate obligations. Suppliers with multiple manufacturing plants might be able to transfer orders from one to another to meet urgent delivery requirements.

Returning to normalcy

It's not clear how long it will take the supply chain to return to normalcy, but if what we are in now is the "new normal," design engineers and motion control experts are armed with more capabilities to manage change together than ever before.