Designers for heavy duty motion control applications have traditionally specified hydraulic cylinders for their high speed, heavy load handling and resilience, while reluctantly accepting the accompanying need for supporting infrastructure, messy fluid handling and limited digital capability as necessary evils. However, recent advancements that embed hydraulic technology within electric linear actuators have been delivering the benefits of hydraulics without their drawbacks.

A prime example of an application capitalizing on this conversion has been the optimization of seed depth control for multi-row agricultural planters. Graham Electric Planter, a Colorado-based agriculture technology innovator, developed a solution using electro-hydraulic actuators from Thomson Industries, Inc. It equips conventional seeders for real-time, interactive seed depth control without the mess, intrusiveness or high maintenance of hydraulic cylinders.

Keeping things simple

Farmers planting corn, soy and other row crops usually know how deep to plant their seeds for maximum yield, but achieving that depth consistently amidst soil conditions that change daily from field to field, row to row and even within rows is a challenge. Planting seeds too shallow, for example, could cause rooting too close to the surface, while planting too deep could delay crop emergence.

Most tractor-pulled planting rigs in use today are equipped with mechanical springs that apply downforce on seed applicators to keep furrows at the right depth ̶ but have no way to adjust to changing soil conditions.

“We met a lot of farmers who weren’t ready to buy a new planter but wanted something that handled soil changes better than the springs they were using,” said Graham Managing Partner Marty Graham.

Graham set out to replace mechanical springs with actuators that would adjust quickly in near real time. Committed to a philosophy of keeping things simple, Graham determined that the actuation solution he needed would require the following characteristics at a minimum:

- Ability to withstand the elements

- Resistance to shock loading

- Minimal external infrastructure requirements

- Clean, low-maintenance operation

- Wireless integration

Traditional hydraulic cylinders met the first two requirements, but Graham ruled these out.

“We wanted to avoid hydraulic cylinders because they are messy, and there are lots of fittings, hoses and wiring all over the place,” he said, adding that cylinder support systems tax already overloaded hydraulic systems needed for handling other functions. They also require an elaborate fluid-delivery infrastructure, which has the potential to leak and create hazardous messes.

Ruling out hydraulic cylinders led him to electric actuators, but they didn’t have the resilience he needed.

“If you're going through the field and hit a pack of dirt or a rock, the actuator needs to be able to give a little,” said Graham. “Normal ball-screw-based actuators could bend, and you’d be replacing actuators all the time.”

A hydraulic system in electric actuator’s clothing

As he continued to explore options, Graham found that Thomson offered an electric actuator with an embedded hydraulic fluid chamber that delivered the durability and communications capabilities that his application required ̶without the need for a complicated, high-maintenance external infrastructure.

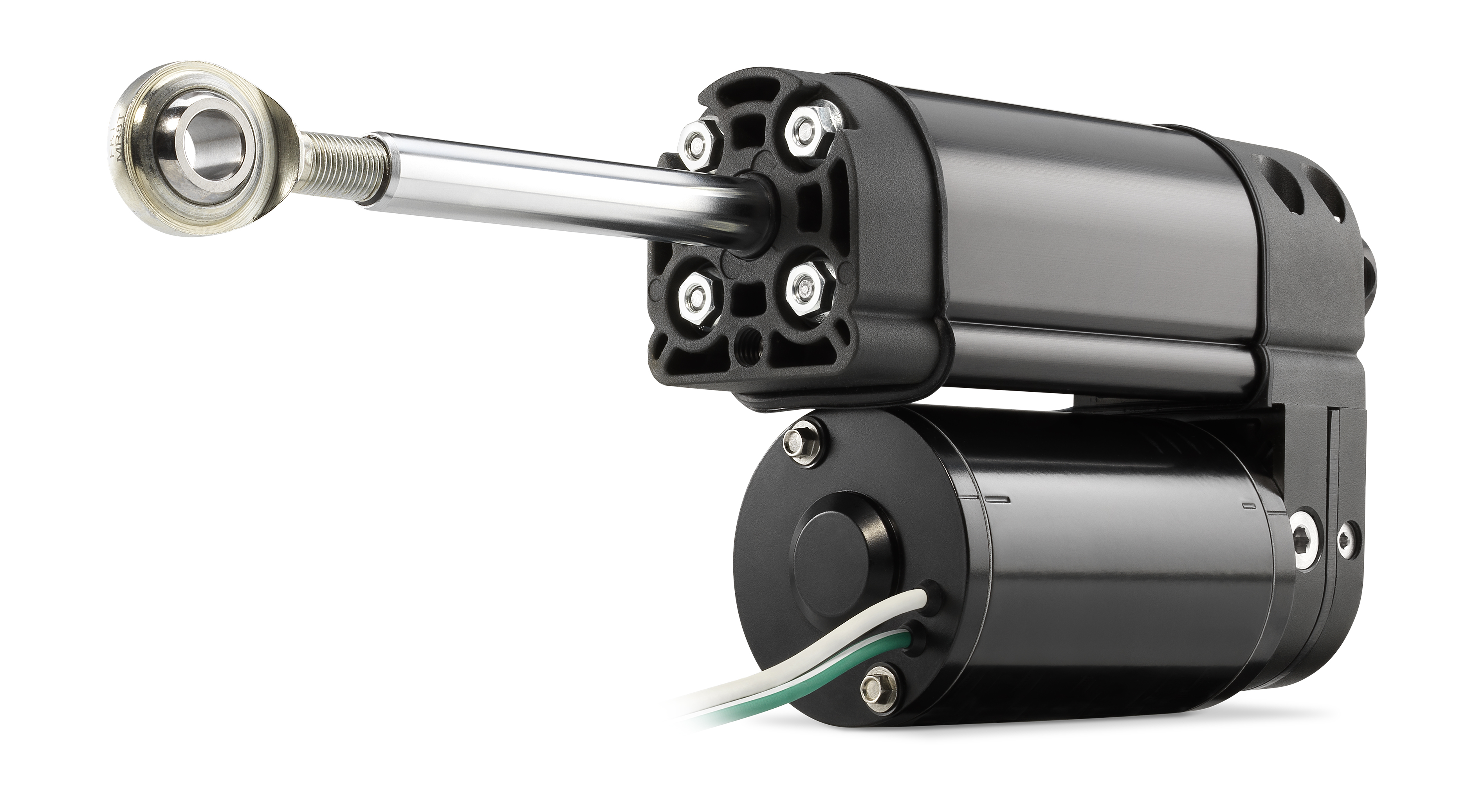

The Thomson H-Track electro-hydraulic actuator has the smallest mounting envelope in its class and uses a patented valve and reservoir design within that footprint. An attached motor controls the direction of the fluid flow within the actuator, and split tanks linked by a shuttle valve provide the back-pressure relief that gives the system its resilience.

The H-Track actuator itself takes up less space than a hydraulic cylinder but doesn’t require an external fluid reservoir for running fluid supply lines to each crop row.

H-Track actuator housings are completely sealed, weatherproof, dust-tight, corrosive resistant, and tested for IP67 static rated for temporary submersion and IP69K high-pressure washdown. The actuator also provides hydraulic fluid options of up to 180°F (82°C). Units are lubricated during assembly, requiring no adjustments or maintenance after they leave the factory and ensuring consistent performance for the life of the actuator.

“We couldn’t find any other product that does what the H-Track does,” said Graham. “The self-contained, hydraulic chamber is key. Other vendors are trying to accomplish what a relief valve in a hydraulic chamber does, but it is not nearly as good as what Thomson is providing to us today.”

The Thomson H-Track electro-hydraulic linear actuator enabled Graham Electric to implement a compact, wireless electric seed depth management system that could pay for itself within the first year of operation.

Electronic depth control in action

The Graham depth control system is paired with a vacuum-driven seeding disk that deposits the seeds in the soil. A typical planter seeds up to at least 24 rows per sweep with one depth control unit, and thus requires one actuator for each row.

Graham customizes a depth control unit for each farmer's application. In a typical configuration, gauge wheels ride in the seed trench behind the seeding disk. A load cell sensor monitors the gauge wheel depth and sends readings wirelessly to the control software. An algorithm determines whether the gauge wheels are riding too high or low and signals the actuator to expand or reduce the downforce accordingly. “If the H-Track electro-hydraulic actuator gets a signal that there is too much pressure, it just releases, which signals our electronics to reset it, and it goes back to where it was,” said Graham.

Customized per each farmer’s requirements, Graham Electric’s depth control system relies heavily on the Thomson H-Track actuator to maintain control of its seeders.

Only two wires connect each actuator to a companion wireless circuit board mounted behind it. In addition to enabling the actuator to receive data from positioning sensors monitoring the depth, the circuit board enables the sharing of real-time status updates with the control dashboard, integrating it with a full picture of the seeding operation.

With Graham’s depth control sytems, planter operators are able to monitor and adjust the pressure status of each actuator, which are represented by the yellow bars on the left.

“We're usually plus or minus one inch off our set point, varying actuator stroke between 1.24 and 3.25 inches,” said Graham. “If farmers are planting on terraces or have very loose soil, then they might pull it up to zero stroke, or if it's really hard ground, they might have to push it all the way, but very rarely will they have to use the full stroke capability of the actuator.”

The most pressure the actuators ever need to apply is typically 50 to 100 pounds above the 250-pound weight of the seeding unit itself. This is well below the H-Track’s load handling capability of 4800 pounds.

Graham installs the system with minimal disruption to legacy systems. It uses the 12-volt battery already on the system and requires no additional fluid handling systems or wires. There are also fewer mechanical parts that might break, leak or require additional maintenance. Electric control provides clean, smooth linear motion without hydraulic plumbing or other expensive componentry. The H-Track's power demands are significantly less than those of a full hydraulic system as the actuators require power only when in motion..

“And the wireless communication eliminates the harnesses, cabling and wiring that would otherwise be necessary, further keeping to our commitment to simplicity,” Graham said.

Reaping the benefits

Graham estimated that changing from springs to electric seed depth control will improve yield by at least 5 percent. He calculated that a farmer that gets 200 bushels of corn per acre should expect a 5-6 bushel increase, which would bring in $18 an acre or $18,000 per thousand acres in the first year ̶ far more than the cost of conversion. That benefit accrues each year, along with lower cost and simplicity from deploying the wireless features of the Thomson H-Track actuator, and greater resale value.

“The H-Track with the self-contained hydraulic chamber was the backbone of the entire product,” Graham added. “Once we had that, we were able to finish our design and turn it into the commercial product that we've been selling now for two years. Without the benefits of an electro-hydraulic actuator, the entire product would be dramatically different.”

Graham and his team are now addressing other seeding automation issues, including some that involve electro-hydraulic actuators, and others that employ traditional electric actuators ̶ all of which are wireless.

Farmers running multi-row seed planters (left) that incorporate Graham’s depth control system with Thomson electro-hydraulic actuators (right) have been experiencing improved yields and returns on their investments in less than a year.