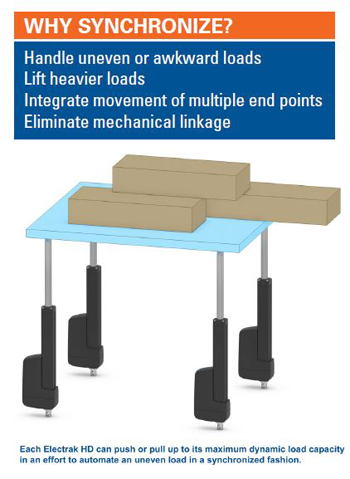

Add Even More Control and Power with the Synchronization Option

Electrak HD’s control features undergo thorough testing at Thomson to ensure your machines are prepared for countless application challenges – both expected and unexpected. With the new synchronization option, machine designers are now able to easily conquer not only heavier loads but the sometimes unforeseen obstacle of actuating uneven loads as well.

Not all applications present machine designers with ideal conditions in which to work. For example, a load requiring actuation may be much heavier on one end, which could lead to potential damage to the machine or its components if handled improperly.

To address situations such as this, the synchronization feature allows two or more Electrak HD units to share and evenly distribute a load. This capability, which can be utilized with the simple flip of a switch, opens up new application opportunities where a single HD actuator cannot handle the load.

At the same time, the use of multiple, heavy duty HD actuators allows users to electrify additional movement with their loads compared to hydraulic solutions.

Benefits of Synchronization

- No more “bouncing.“ When multiple actuators with synchronization are installed, designers can take advantage of a more stable and potentially quicker lift, no additional guides, and improved handling of uneven loads.

- Installation is simple and lowers the complexity of wiring up the system since the actuators have integrated controls for the synchronization feature (as opposed to an external sync control).