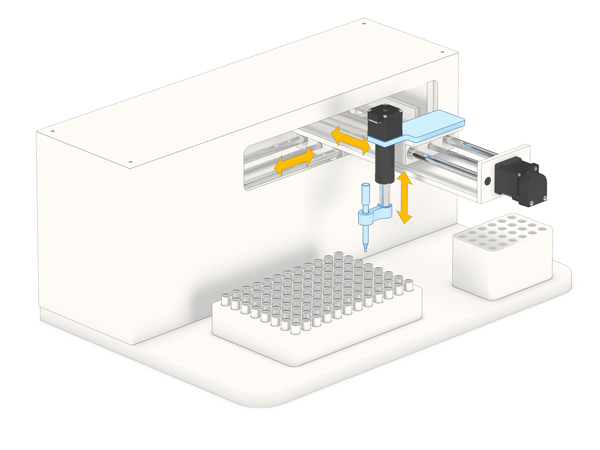

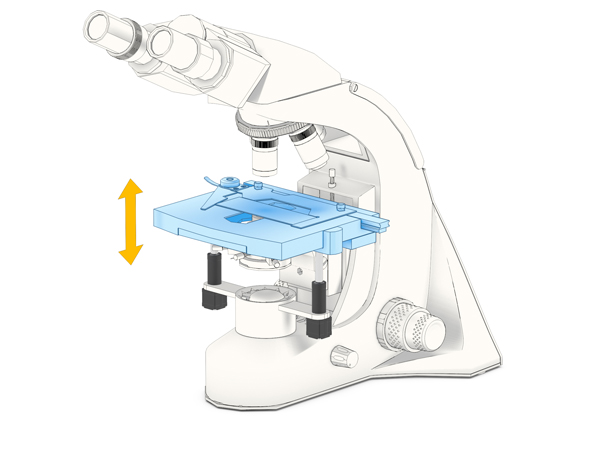

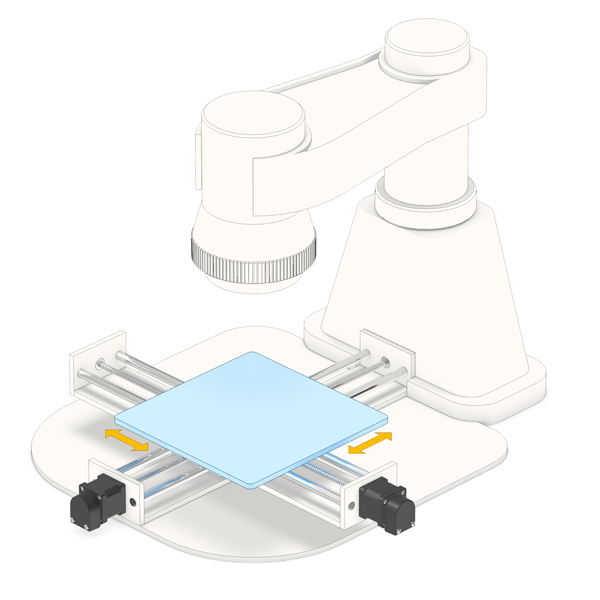

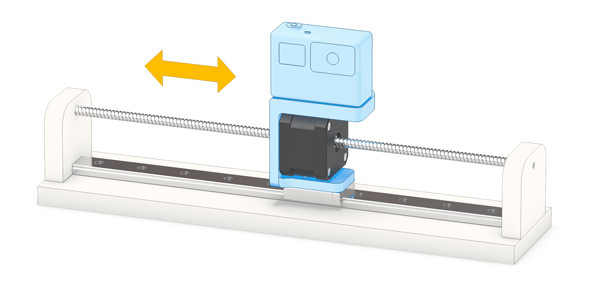

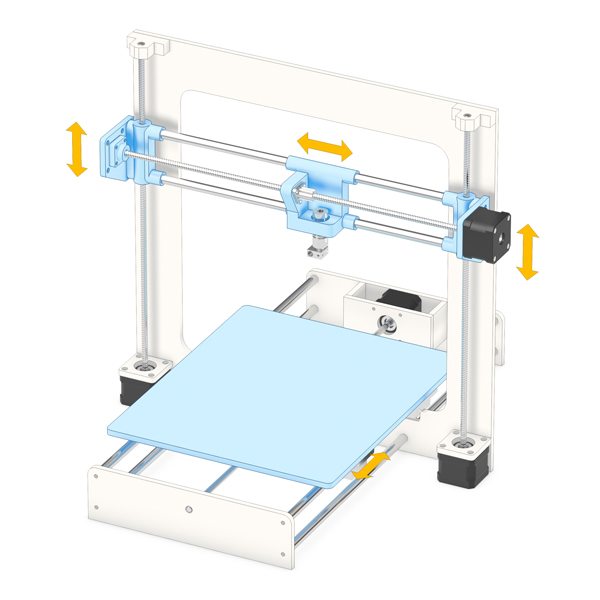

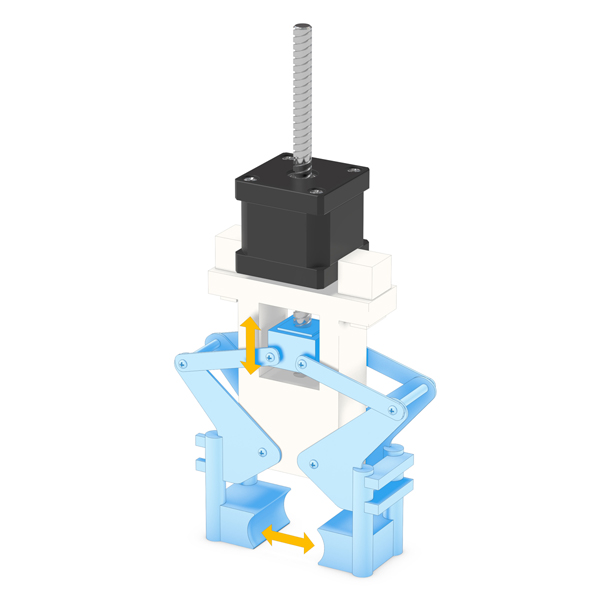

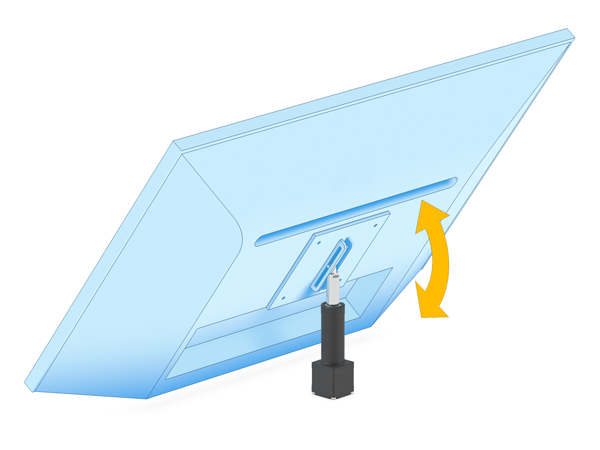

Where to Use Stepper Motor Linear Actuators

These common applications show that stepper motor linear actuators reduce the total number of components in your design, while minimizing space requirements, and making assembly and maintenance quicker and easier. Examples are shown for all three configurations – rotating screw (MLS), rotating nut (MLN) and actuator (MLA).